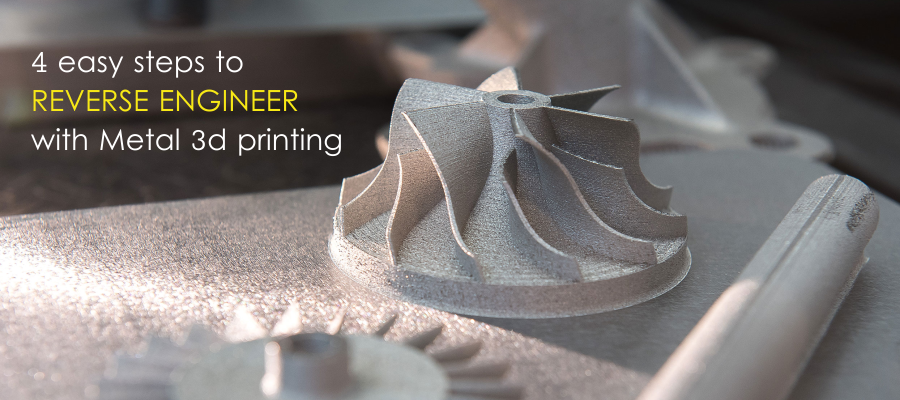

Reverse engineering is a method which enables users to replicate an object or a part with the help of 3D printing. With this technology, a user can scan a 3-dimensional object and convert it into a CAD file which can then be printed using a 3D printer to get an exact replica of the object or spare part.

In manufacturing industries, many old machines are idle as some parts have failed and the company couldn’t get them from their original manufacturer. In such cases, the parts can be scanned and 3D printed, which would make the machine functional again.

Reverse engineering has applications in many industries such as Aerospace, Defense, General Engineering, Oil & Gas, Energy, and Automobile spare parts. There are multiple benefits of reverse engineering such as the production of obsolete parts that are no more produced, to produce of complex existing parts without having to design them in CAD software, reduction in machine downtime, improve efficiency of existing parts and cost savings.

Steps for reverse engineering:

1. Determine units & take part dimensions

In reverse engineering, the first step is to determine units. Gather some information on where the part was made, and more specifically where it was designed, this will help you to understand that the part is in Metric or Imperial unit. Once you have a hunch about the units being used, capture the data from the existing part. Start with taking measurements on some key features like the length, width, and diameter of the main body.

2. Plan for your Design & Understand the object thoroughly

The next step is to start planning out your design for 3D metal printing. Some products have complex shapes so it is important to get a complete understanding of the object. If the part is of assembly, you need to check the critical areas of part application so that the functionality of the part doesn’t disturb the interrelationship between the various parts. When disassembling the object, be sure to keep an eye on fit and feel of the parts. If you have a strong understanding at the start, it will make the planning and design of your product much easier.

3. Laser-Scan & Start CAD designing:

Now physical part or object has to be scanned using 3D scanning technologies like Laser scanners, structured light digitizers, or Industrial CT scanning. The CAD software programs turn the point cloud or mesh that was received from the scanner into a polygonal model. The resulting mesh is cleaned up, smoothed, and sculpted to its required shape and accuracy.

Then you need identify the design flaws in the CAD model and also work on the design modifications if required. Also, you need to detect the areas where some modifications for the purpose of printing are required, for instance adding support structures where there is risk of breakage. The CAD model is then converted to an STL file and the object is sliced into 2D layers stacked on top of one another. The STL file is then transferred to the printer using custom machine software.

4. 3D Print the CAD file:

The last step is the simplest step as you just have to 3D print the STL file and wait for the output i.e. replicated 3D object. After the file and material are loaded into the printer, the printer is set-up with printing parameters. The 3D printer builds the model by depositing the material layer-by-layer. After the first layer of the physical model is done, the 3D printing machine builds another layer of powder on top of the first layer. This process is repeated until the object is completed. The completed object is then sent for post-processing where it is finished and completed for dispatch.

Conclusion:

3D technologies are enhancing not only because of ability to create something new but also because they can reverse engineer those products that already exist. Reverse engineering gives way for design improvement, reuse of old objects and increase productivity at lower costs.