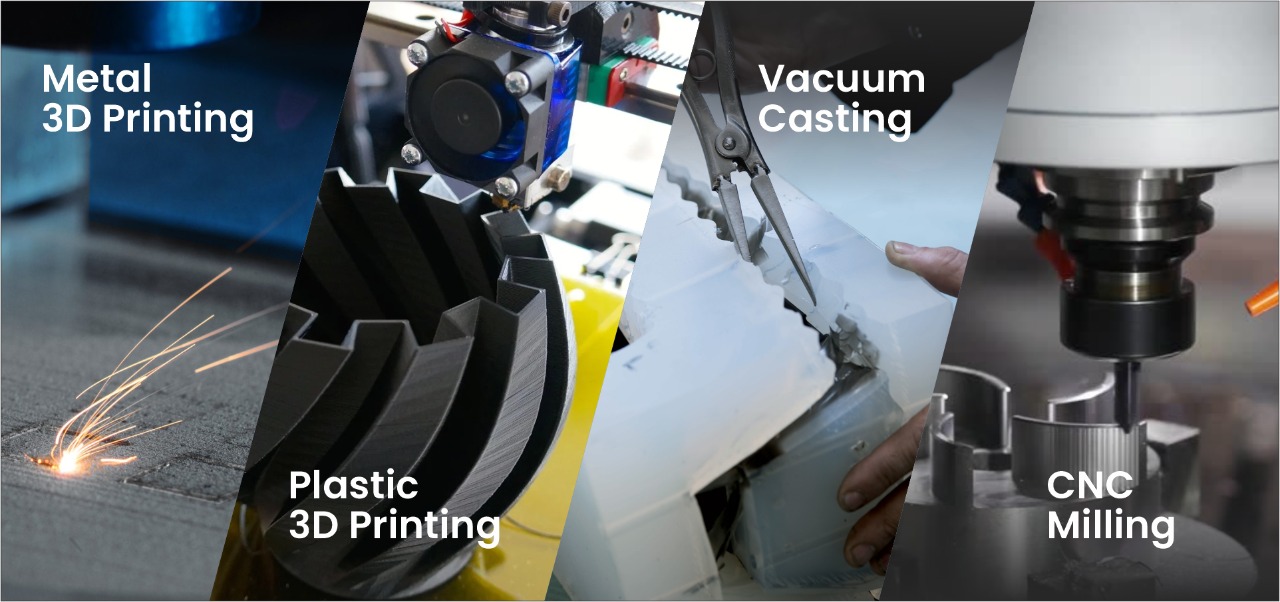

Metal 3D printing

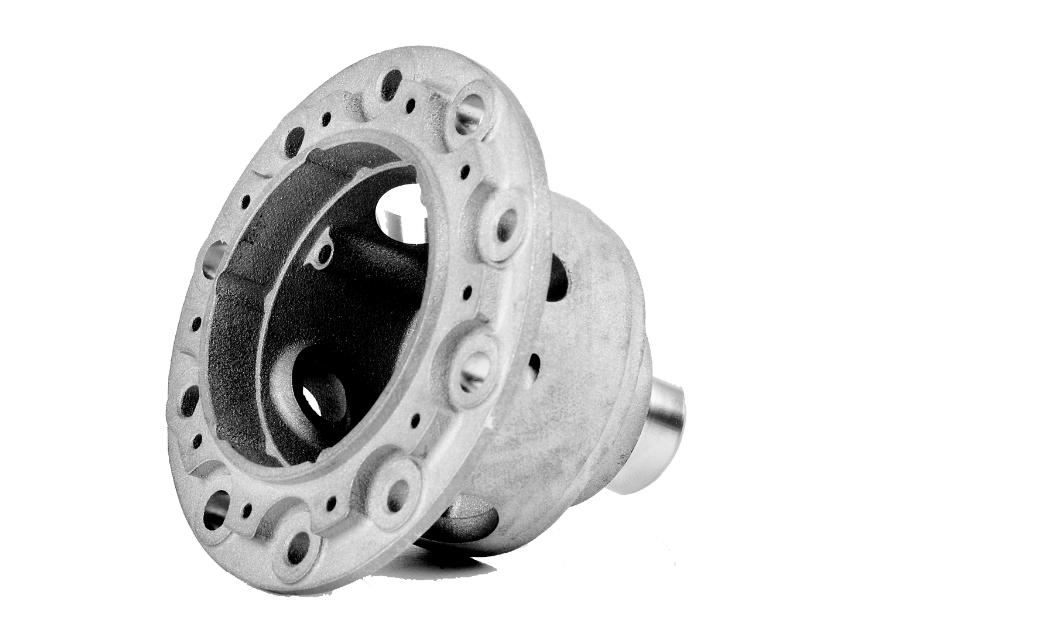

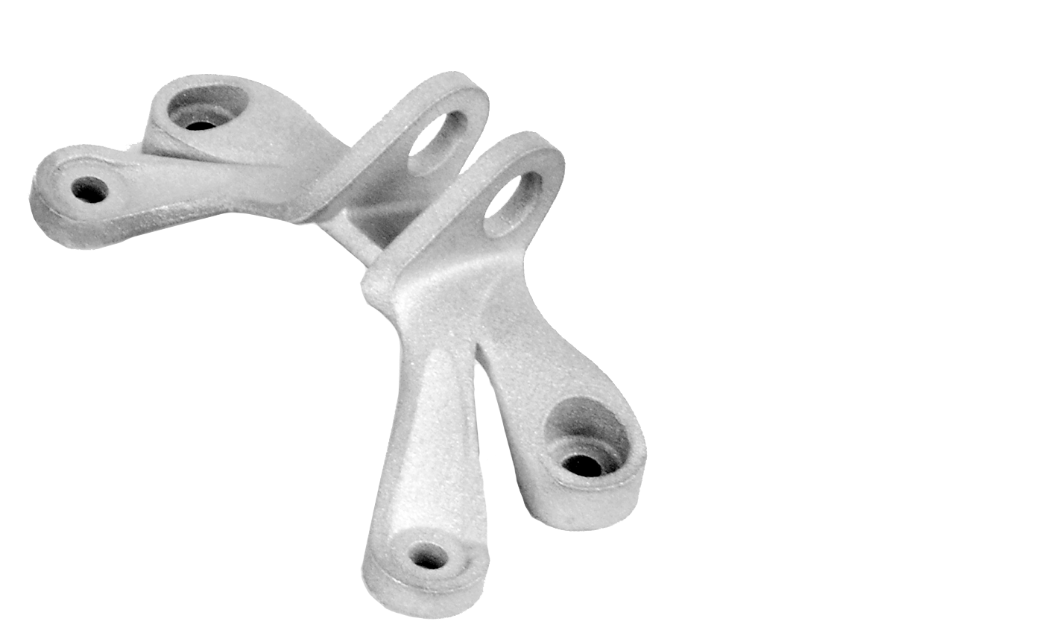

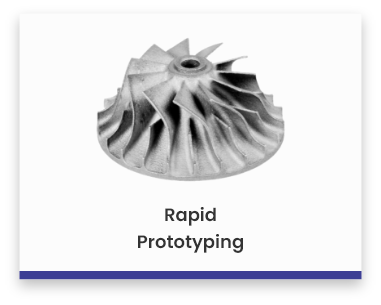

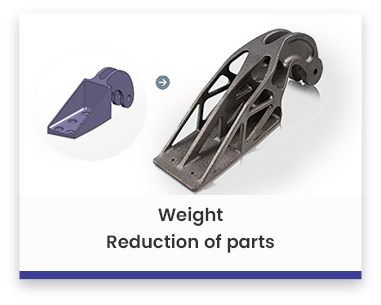

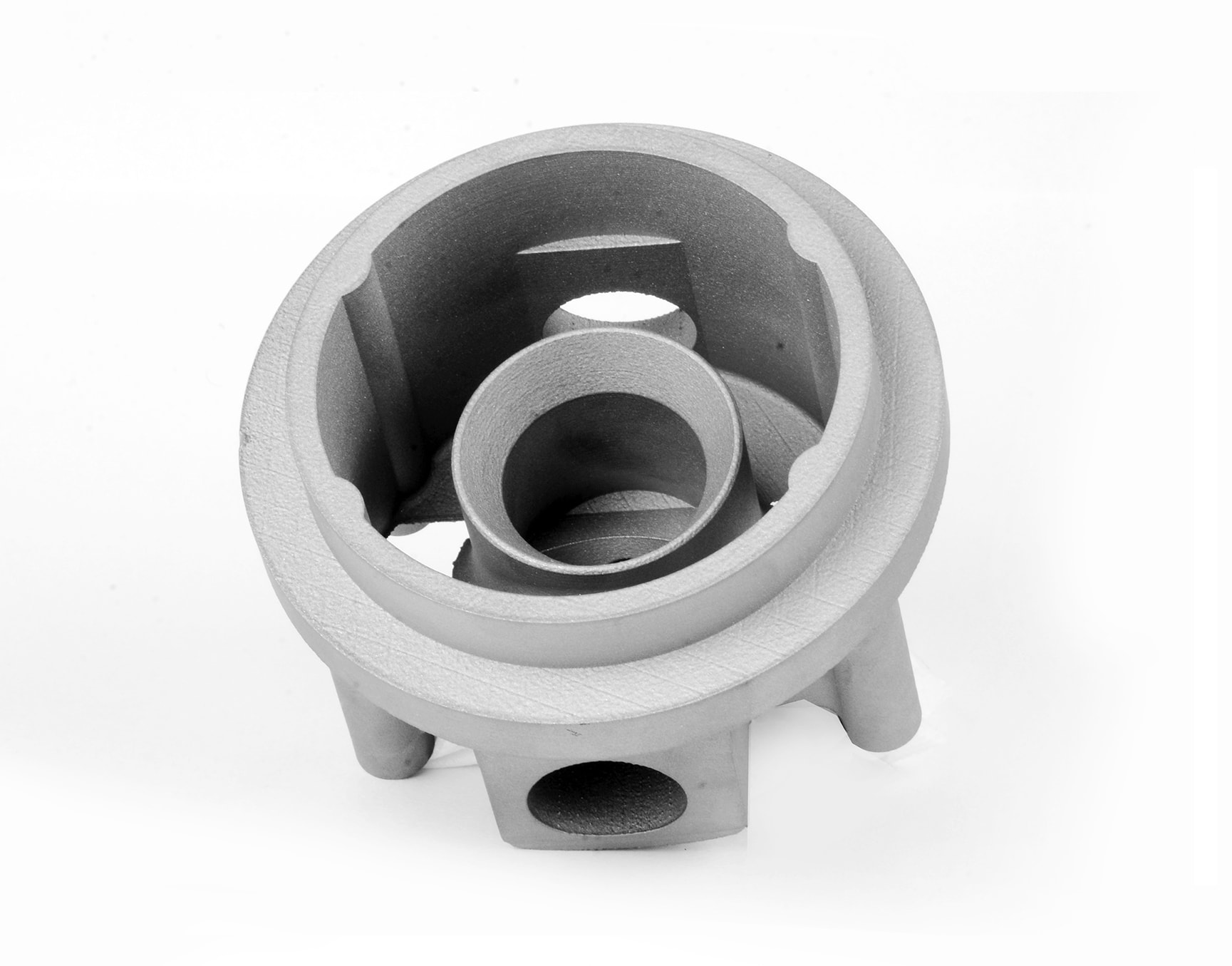

Metal 3D printing (Additive Manufacturing) is a novel manufacturing technology that has the potential to revolutionize the way metal parts are made conventionally. Selective Laser Melting (SLM), one among several sub-technologies of metal 3d printing, produces one-of-a-kind, robust, and lightweight parts, even for the most complicated 3d printing applications, by combining the mechanical qualities of high-performance metal alloys and the design flexibility of 3d printing. Metal 3D printing produces finished parts and perfect functional prototypes that might never have been possible to manufacture using traditional manufacturing techniques.

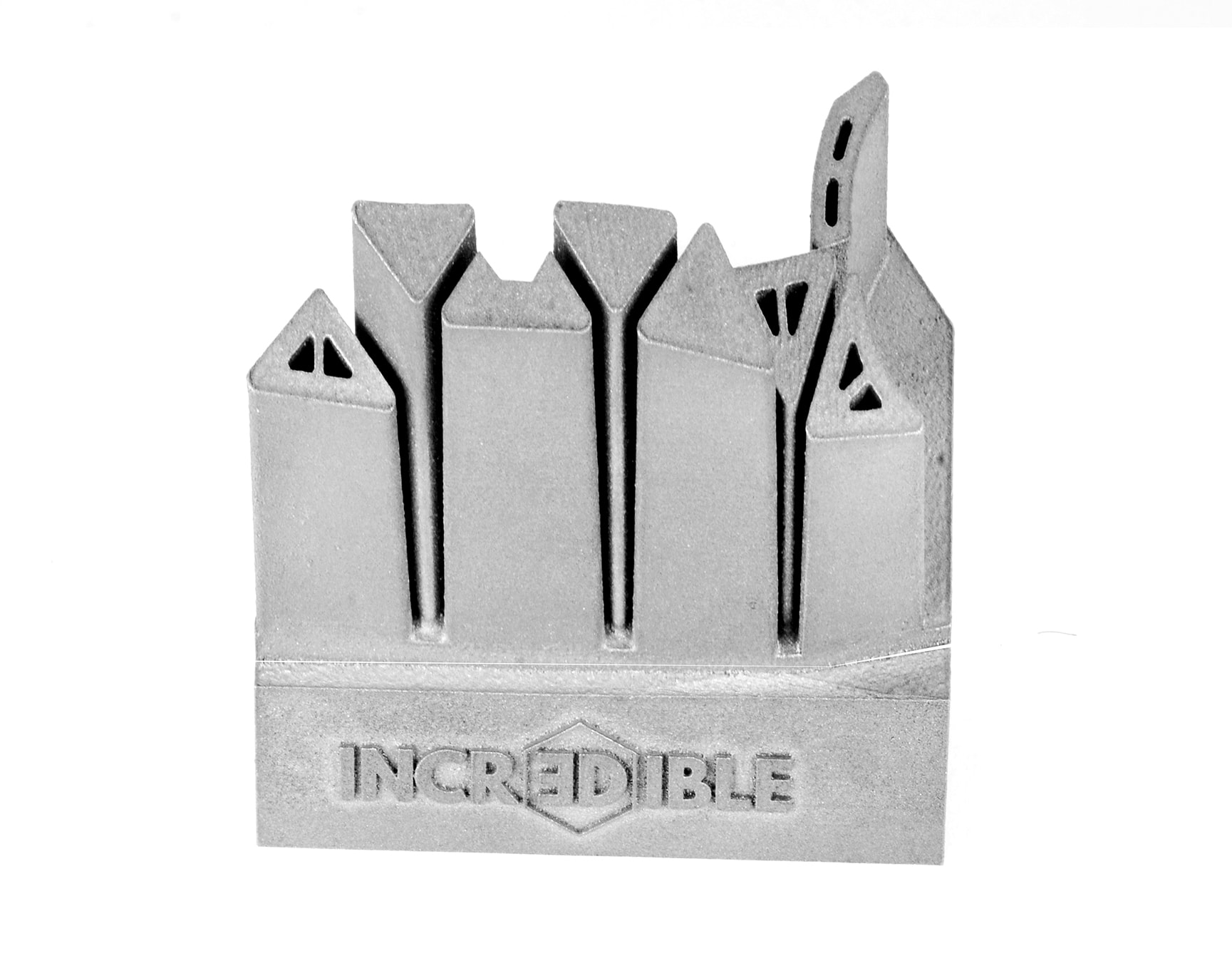

Incredible 3D is the leading provider of metal 3d printing services and products in India. Without using dies and tools, we are capable of producing complicated and elaborate shapes. Using the 'Near Net Shape' manufacturing process we produce parts that are made very near to the necessary dimensions, with 0.2 mm precision.

At Incredible 3D, we offer various 3d printing applications that are used in several industries. Here, our team starts the procedure by creating a CAD model of a part. The model is divided into 50-micron-thick layers. The 3D printer continually spreads a layer of metal powder on the build plate, which is melted by the LASER according to the CAD model measurements. Over time, the part is constructed layer by layer. The pieces are mechanically strong and dense, allowing them to be employed in engineering applications.

As the best metal 3d printing services provider, we create the most cost-effective parts in much reduced time.

Application Industries

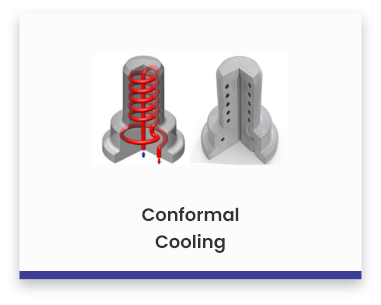

Benefits of Metal 3D Printing

at low cost

lead time

Optimisation

Development

Engineered parts

Management

What Our Client's Say

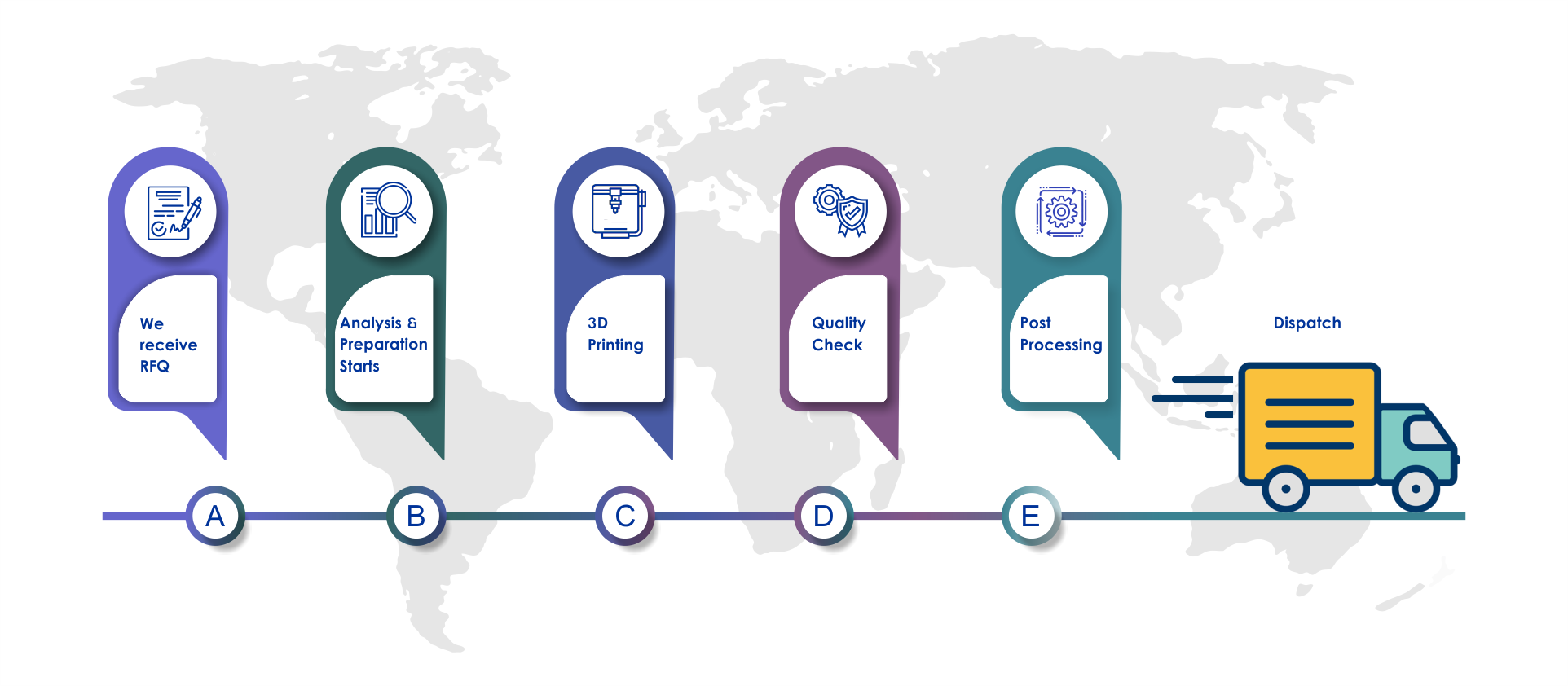

Process Flow