Introduction of Metal 3D Printing

Metal 3D printing (Additive Manufacturing) is a latest manufacturing technology which has the potential to revolutionize the way metal parts are being manufactured traditionally. Complex and intricate shapes can be produced without dies and tooling. It is a ‘Near Net Shape’ manufacturing process where parts are built very close to required dimensions, as precise as 0.2 mm accuracy. Metal printing has several sub technologies available in the market such as SLM, DMLS, DMD etc, and Incredible AM is working on SLM (Selective Laser Melting) process.

Our Process

The process of metal 3D printing begins with the CAD model of a part which needs to be produced. The model is sliced into thin layers of 50 microns, then the 3D printing device spreads a layer of metal powder on build plate which is melted by LASER as per CAD model dimensions continuously. The part gets built layer by layer over the period of time. They are mechanically strong and dense and can be directly used in engineering applications.

Features of Metal 3D printing

RAPID PROTOTYPING

A tool less process of manufacturing, basically for small quantities. Customers need to get CAD design file as an input to the printing device. Software packages slice the design into small layers and produce them into a fully functional that can be used for testing. This reduces the time, cost and efforts of product development process.

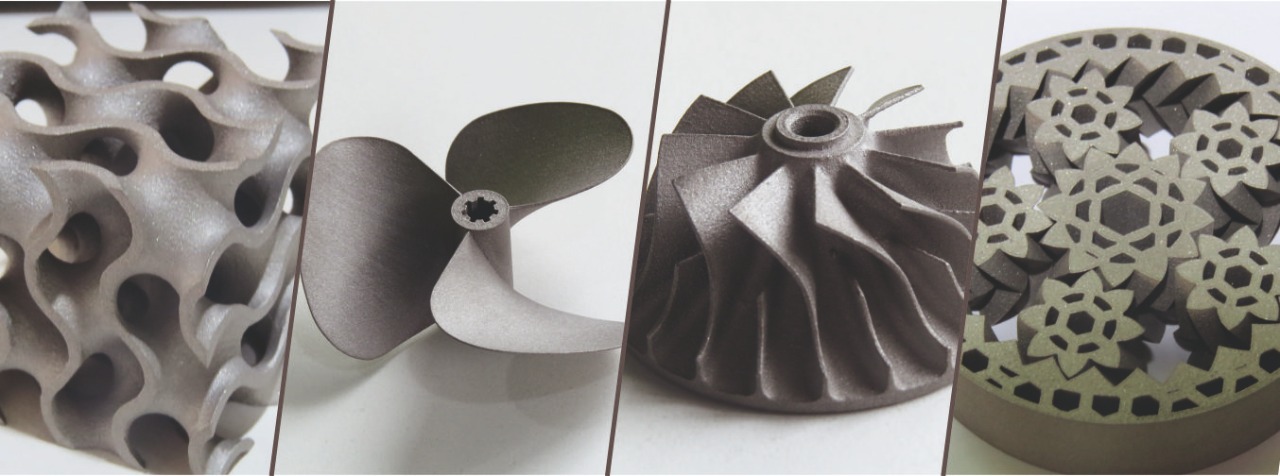

WEIGHT REDUCTION

Metal 3D printing has made it possible to reduce a part weight through innovative lattice structures. The material is structured in such a way that it can sustain heavy load at lowest part to weight ratio.

PARTS CONSOLIDATION

A group of parts joined together by a variety of means such as welding, bolting, riveting etc. These joining processes have limitations, and the chances of failure are high due to rise in temperature and pressure. In this process, parts are merged together in the CAD model with some design changes without compromising the functionality of the part.

CONFORMAL COOLING

Conformal cooling channels can be 3D printed in a variety of cross sections such as rectangular, circular, elliptical, half-circular etc. Cooling channels can be circular, elliptical, spiral etc. These complex cooling channels improve the overall efficiency of the plastic part process resulting in reduction of cooling cycle time by up to 40% along with improvement in surface finish.

REVERSE ENGINEERING

Advancement in laser technology has enabled manufacturers to scan a 3-dimensional part and convert it into the CAD file. Obsolete machines can be revived through reverse engineering by scanning damaged parts and producing them through 3D printing without contacting the original manufacturer.

VIRTUAL INVENTORY

OEM’s have to maintain a huge inventory throughout the year which incurs space as well as cost. However, with the advent of additive manufacturing, inventory can possibly be digitized and used whenever required

CUSTOMISATION

Additive manufacturing opens up the horizon for ease of customization of products.

Applications

- Defence

- Aerospace

- Automobile

- Tools & dies

- Education

- Energy