What are the main challenges in 3D printing with metal, and how do we overcome them?

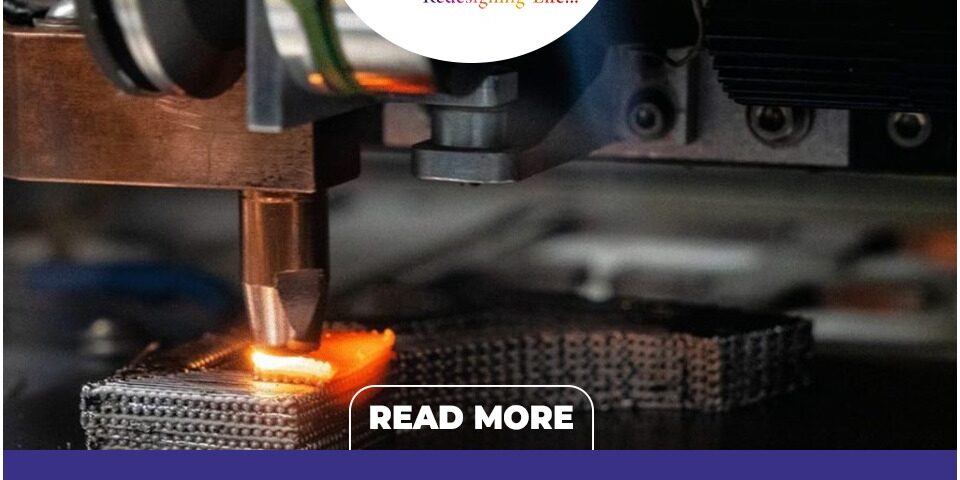

Metal additive manufacturing is a modern technology with enormous potential. However, it poses several challenges that engineers and researchers are trying to overcome for widespread adoption and successful implementation in various industries.

Metals behave differently under high temperatures. Other factors like melting point, thermal conductivity and powder size distribution of metal powder also influence the process. Overcoming this challenge involves extensive research to develop new metal alloys specifically designed for 3D printing.

Another challenge is obtaining high-quality, smooth surfaces in 3D-printed metal objects. Issues like porosity, uneven layering, and rough finishes are common. Advanced printing techniques, precise control of printing parameters, and post-processing methods improve surface quality.

Warping and deformation in the printed object due to thermal stress are common issues. Managing these residual stresses requires optimizing printing parameters, including temperature control, and utilizing support structures to minimize distortion during cooling.

Printing intricate and complex metal parts can be challenging due to the need for support structures, which can be difficult to remove and leave rough surfaces. Innovations in printing techniques, such as powder bed fusion and directed energy deposition, are being explored to address this challenge and enable the production of complex geometries without compromising quality.

3D metal printers and the metal powders are expensive. Researchers focus on developing more affordable printers and finding ways to recycle and reuse metal powders to reduce overall costs.

Ensuring the structural integrity and quality of 3D-printed metal parts is crucial, especially in industries such as aerospace and healthcare. Establishing standardized testing methods and certifications for 3D-printed metal components is essential to guarantee their reliability and safety.

After printing, many metal parts require additional machining and post-processing to achieve the desired specifications. Integrating 3D printing with advanced machining techniques can enhance the accuracy and surface finish of the final product.

By overcoming these challenges, researchers, engineers, and manufacturers are pushing the limits of 3D metal printing. Continuous innovation, research, and collaboration between industries and academia address these challenges and unlock the full potential of metal additive manufacturing.

Incredible AM Pvt Ltd, the pioneer in 3D printing in India, has a world-class manufacturing facility that aids in manufacturing 3D-printed metal objects. We have the best 3D printing machine and use the best metal powders. Besides, our skilled and knowledgeable team strives to overcome these challenges in the best possible ways.