As new materials, industries and processes emerge, 3D printing’s transformative potential will save robot designers time, resources, and produce better robot designs and manufacturing for years to come. While many robotics companies now use 3D printing in their robot designs, experts predict this partnership will expand as the advantages of additive manufacturing gain greater visibility as a smart manufacturing. In the months and years to come, the versatility and customization that 3D printing provides will be more commonly embraced by businesses. Both technologies complement each other to generate decent effects, which are carried on to consumers for a stronger and more efficient robot: additive manufacturing/3D printing and robotics.

3D Printing and Additive Manufacturing for Robotics Industry

3D Incredible knows well that there could be multiple industry requirements for robotics applications. Thus, with custom tool variants, we provide a comprehensive catalogue of product offerings. That may be part of why, for the robotics industry, additive manufacturing is perfect. Robotics engineers are still finding more flexibility, performance, and precision. Additive production facilitates prototyping, tooling, manufacturing which lowers costs and time to market and also helps robotics engineers accomplish their targets & goals. We can customise designs for robotic applications according to consumer requirements and optimise their designs based on research and testing using quick prototyping made possible by 3D printing. Throughout a multitude of markets, additive processing has unique benefits:

- New tooling for Robotics Manufacturers

In mainstream manufacturing, additive manufacturing is now being used to create tools, jigs, and fixtures to help manufacture complex products. The customization of components, fitted for a particular job, is an integral fixture within their landscape for the robotics industry. Robots are not always engineered and produced as robots of the same kind. More commonly, they are customized to a specific requirement. Tasks that are “dirty, dull, or dangerous” for humans are frequently performed by them, but their added benefit is derived as they execute particular tasks previously performed by a person. In recent years, 3D printing has been used widely to achieve efficiency and complex functions, allowing for the development of custom robotics. Because various robots have different operating specifications, the ability of 3D printing to produce personalised parts that are specific to the task and there has been a fantastic opportunity to print materials that can hold up. Making custom components illustrates how there are various applications for different markets for 3D printing and additive manufacturing.

- Rapid Manufacturing of grippers

Plastic and Metal 3D Printing can be used to print robot grippers easily with desired accuracy.

New design modification of the product which robot is handling demands new grippers as per modified design. Here 3D Printing can help in producing any shape size gripper.

- Robot spares

Most of the time the spares of the advance robots have to order and imported from abroad countries. Old robot models face difficulty as the spares manufacturers are not available or stopped manufacturing spares. This results in stoping of production lines. Hence 3D Printing proves here as boon because inventory can be quickly produced with the help of it.

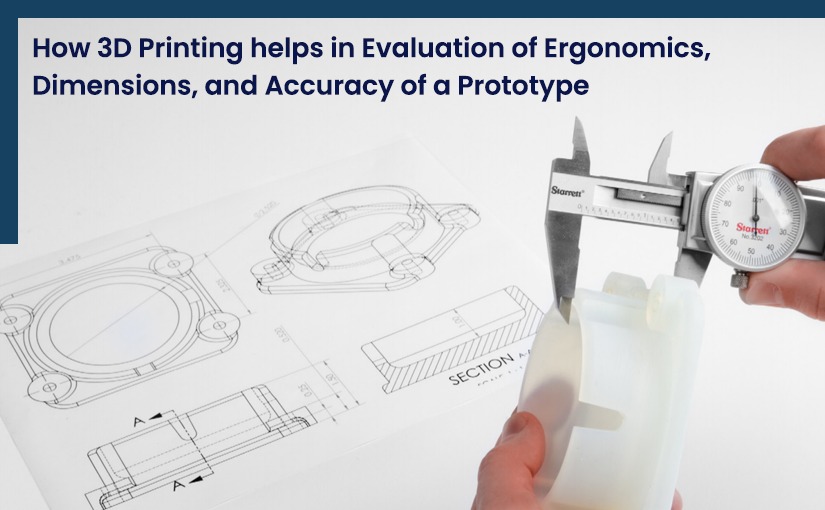

- Rapid Prototyping

3D printing is suitable for quick prototyping for robotics design. It takes a lot of trial and error to design robotics. This starts with a framework and various criteria of architecture that are used to meet a planned application or routine. Using a 3D printing process, prototypes can be produced easily, inexpensively, and with little overall risk. A 3D-printed prototype can be generated in a fraction of the time it takes to machine a part. The reduction of processing time and the simplicity of low-volume production associated with rapid prototyping provide unusual versatility in the manufacture of robotic machines. A competitive gain is expedient prototyping, helping robot makers perform better in a market that travels at lightning speed.

- Direct Fabrication

3D printing is not only used for prototyping, to manufacture machines and fixtures. It is very possible that the robot itself – or at least many of its parts – could be generated by 3D printing. Not only is 3D printing a replacement for injection moulding, but it can be used as a different way of building products. Everybody in the robotics industry should realise that with 3D printing, from components to wiring, you can be very imaginative. The potential is immense and will allow the industry to grow faster than using injection moulding with more power. Direct manufacturing through additive manufacturing provides the production process with many economic advantages. Since moulds with additive manufacturing are not necessary, low-volume builds can be productive. This, along with the plethora of 3D printing applications that the robotics industry will have, provides a very innovative future.

- Saving Time and Money

It is easier to satisfy the uncompromising demands of the robotics industry with 3D printing & additive manufacturing. Output usually equals or surpasses cast parts in metal printing. It is more process-dependent within polymers, but a variety of processes can provide parts with properties on par with injection moulded parts. When it comes to larger quantities, it needs the right 3D printing application to win out over conventional technologies. Consider extremely complicated components or sub-assemblies that could be incorporated as suitable candidates for 3D printing development into a single, highly complex component. For businesses, the greatest wins come as they recognise the potential of 3D printing to produce distinctive geometries to radically boost performance, not just to achieve the same performance more cost-effectively.

- Customized Parts Production

Although custom component production is a benefit for manufacturers of robotics, 3D printing can also be useful for repairing robots. On demand, replacement parts and spares may be made. In order to repair parts and designs that may not work, they can be reverse engineered and upgraded. With a 3D printer nearby, it is not important to order a replacement part. It is possible to make it on-site. The whole supply chain as well as the maintenance and repair of robots are literally turbocharged. This advantage may also be shared with other appliances.

Conclusion:

The robotics industry will also take advantage of generating smaller volumes without upfront costs, in addition to designing better tooling, exploiting design freedoms, customising robots, and getting to market quicker using additive manufacturing. With a multitude of uses, 3D printing will have a very innovative future for the robotics industry. Incredible AM Pvt. Ltd. situated in Pune India is a company which is offering solutions from idea, design, printing and post-processing to quality management and assurance by additive manufacturing for Industry 4.0.