Applications of 3D Metal Printing in Medical Industry

What is 3D Printing?

3D printing, also referred to as additive manufacturing is a process in which objects are made by joining or depositing different material such as plastic, metal, ceramics, powders, liquids, in layers to produce a three-dimensional object.Here are the several application of 3d metal printing in medical industry. 3D printing is capable of producing fully dense customised implants, direct from 3D CAD model using a high-powered fiber laser. Some 3D printers are similar to traditional inkjet printers; however, the end product differs in that a 3D object is produced. 3D printing is expected to revolutionize medical, engineering and other fields in the coming years.

Applications of 3D Metal Printing:

Medical applications of 3D printing are expanding rapidly and expected to revolutionize the healthcare industry extensively in the coming years. There are multiple benefits of using 3D metal printing in medical applications such as customization & personalization of patient specific implant, less surgery time, precise bone resection, and enhanced productivity.

There are four major applications of 3D metal printing in the medical field; bioprinting tissues and organs, surgical tools, patient-specific surgical models and custom-made implants & prosthetics.

Let’s discuss these major applications of 3D metal printing in detail:

1. Bioprinting Tissues and Organs:

Bioprinting is one of the many types of 3D printing that is used in the medical field. Bioprinters differ a little from other 3D printers, as rather than printing using plastic or metal, they use a computer-guided pipette to layer living cells, referred to as bio-ink, on top of one another to create artificial living tissues.

These artificial tissue constructs or organoids can be used for medical research as they mimic organs on a miniature scale. They are also being trialed as cheaper alternatives to human organ transplants.

2. 3D printing of surgical tools:

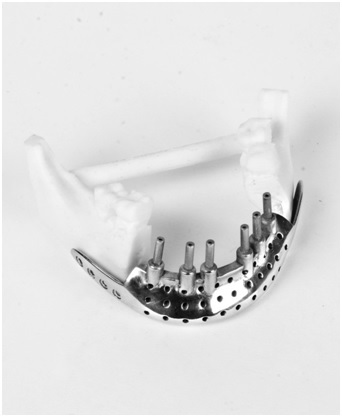

3D printing is an additive manufacturing process which allows the creation of solid objects directly from a digital file. With the recent advancements in this technology, 3D printing is also used for making various orthopedic tools, dental surgical guides & tools like abutments and implant supporting bar. With the help of 3D metal printing, physicians are now able to create guides that precisely follow a patient’s unique anatomy, accurately locating drills or other instruments used during surgery.

Some instruments are based on the ancient Japanese practice of origami, meaning they are precise and can be made very small. These instruments can be used to operate on tiny and complicated areas without causing unnecessary extra damage to the patient.

3. Anatomical models for surgical preparation:

Source: 3Dsystems

The human body is a complex structure and operating on it can get difficult sometimes for surgeons. Currently, physicians solely rely on MRI or CT scans to study or stimulate surgery, which isn’t completely instructive as they are viewed in 2D on a flat screen. However, having a tangible model of a patient’s anatomy will give surgeons a better understanding of each and every part.

3D printing helps in creating patient specific implant organ replicas that surgeons can use to practice on before performing complicated surgeries. The use of 3D-printed models for surgical training is also preferable than training on cadavers, which are costly and not readily available. Cadavers also often lack the appropriate pathology, rather than providing a near representation of a surgical patient, it is more of a lesson in anatomy.

4. Custom-made implants and prosthetics:

Another application of 3D metal printing in the medical field is that it can be used to produce prosthetic limbs that are customized to suit and fit the wearer. Amputees often have to wait for weeks or months to get their prosthetics through the traditional route, which can be troublesome sometimes. The use of 3D metal printing significantly speeds up the process and it also creates much cheaper products that offer patients the same functionality as traditionally manufactured prosthetics.

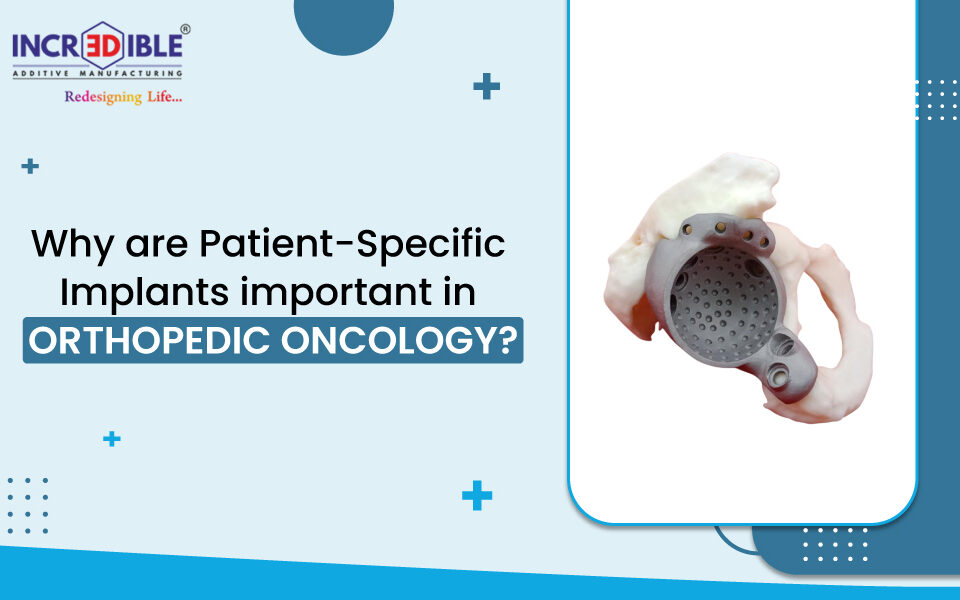

The ability to quickly produce custom implants and prostheses solves a clear and persistent problem in orthopedics, where standard implants are often not sufficient for some patients, particularly in complex cases.

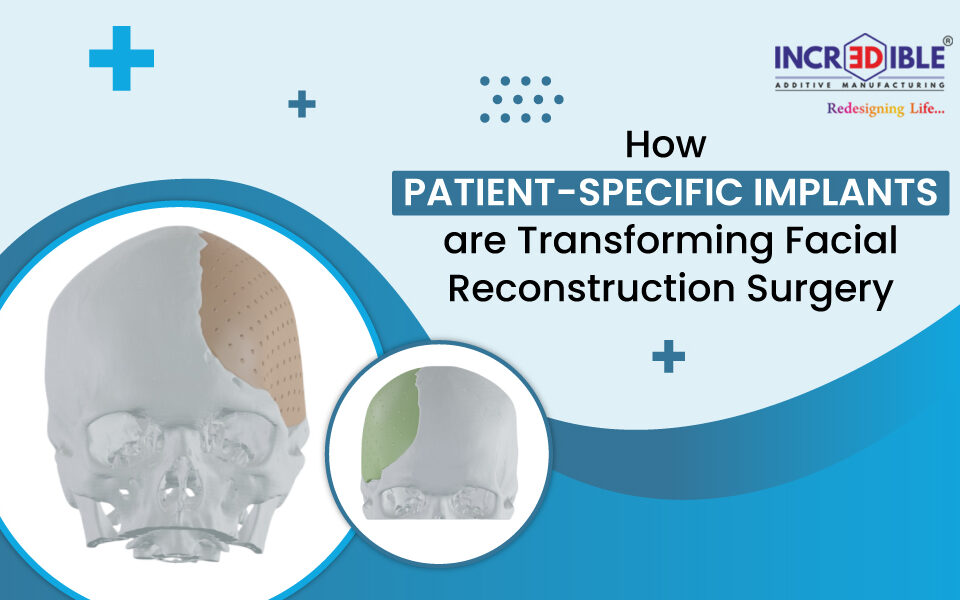

3D Incredible provides anatomically shaped patient specific Implants to reconstruct skeletal defects or enhance skeletal features, hence providing precision in aesthetics and functioning. The custom made implants includes Cranial Implants, Maxillofacial Implants, Mandible Implants, and Orthopedics Implants.

In neurosurgery, the use of these implants and prostheses is very important, as skulls have irregular shapes and it is hard to standardize a cranial implant. Head injuries are severe and when the bone is removed to give the brain room to swell, the cranial mesh that is later fitted must be perfect. Although some plates are milled, more and more are created using 3D printers, which makes it much easier to customize the fit and design.

Conclusion:

3D printing has already become a useful and potentially transformative tool in a number of different fields, including the medical industry and engineering industry. Researchers across the world continue to improve existing medical applications that use 3D printing technology and look to explore new ones. 3D metal printing has already made significant advances in different fields, but some of the more revolutionary applications, such as organ printing, will need time to evolve.

3D Incredible is one of the leading companies that are actively involved in 3D metal printing in India. We offer an extensive range of highly advanced and technologically updated rapid prototyping services across India. We have a state-of-the-art manufacturing facility in Pune, equipped with the latest machinery and 3D printing infrastructure to produce the best 3D printed products.