A Passion for Helping Patients

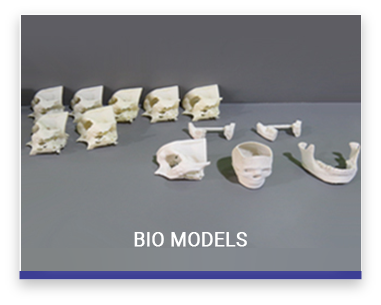

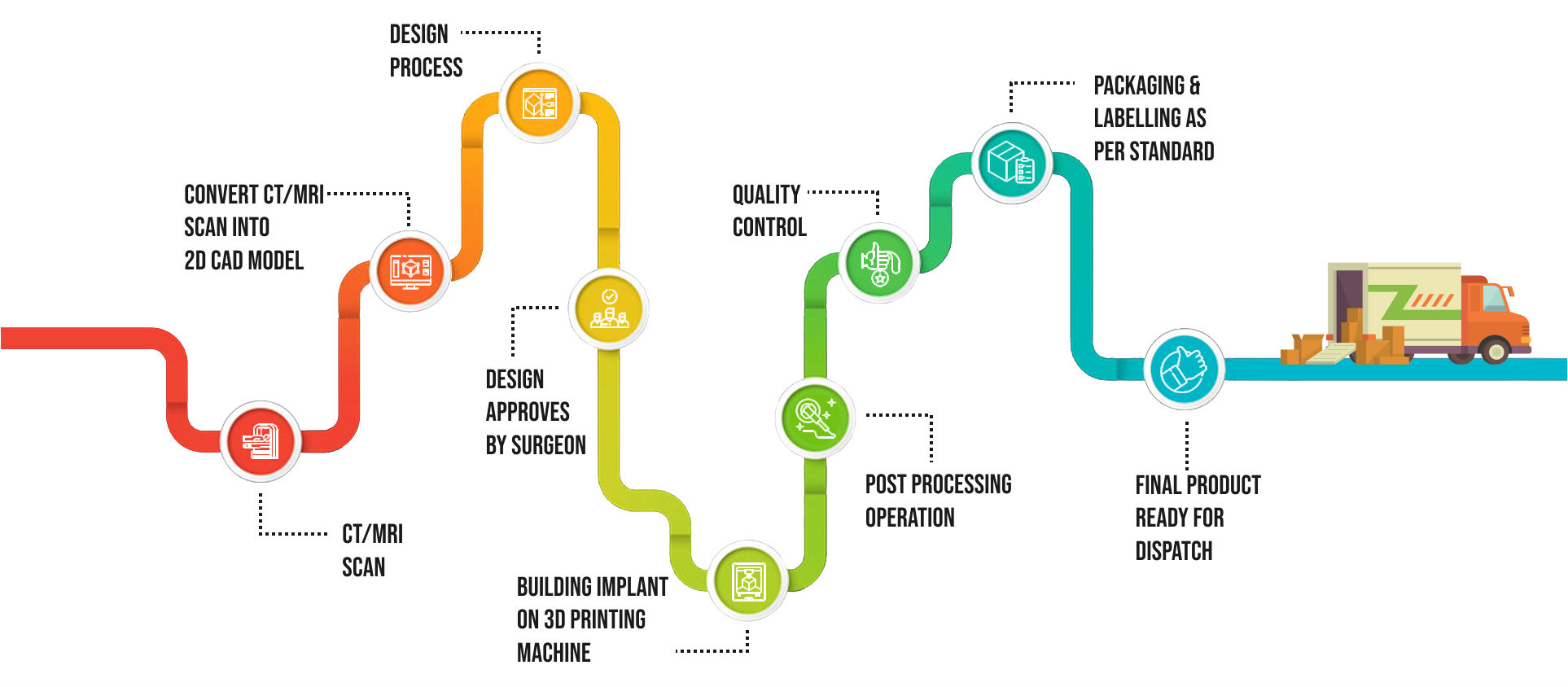

Additive Manufacturing, otherwise known as 3D Printing, is becoming a major tool in the medical industry. 3D Printing in healthcare is frequently used in clinical and research-based activities. The creation of patient-specific implants, organs and tissues, surgical tools and devices, and medicines are some of the 3d printing medical applications that are revolutionizing the medical field. The process starts by developing patient-specific digital models of the structures, to be printed. The model is developed using 3D imaging methods like MRI, CT scan and X-Ray. The adaptability, speed, and relatively low cost of the 3D printing method then allow for the production of small (even single-unit) quantities. In addition to helping hospitals and other point-of-care (POC) organizations plan procedures, the models themselves can be used to explain or clarify difficult medical topics.

Incredible 3D, the pioneer in 3d printing in India, caters to the demand for 3d printing in medical field. We understand that every patient is valuable and deserves exceptional treatment, therefore we offer patient-specific implants, models and surgical tools. We endeavor to develop implants that perfectly fit the anatomy of the patient and give them desired functionality and aesthetics. The 3d-printed implants, models, surgical tools and services help surgeons to effectively serve each patient and make him/her happy.

At Incredible 3D, our popular brands ULTIFIT creates patient-specific cranial implants, CONFIDENCE deals in maxillofacial and mandible implants, and LIMBSAL ORTHO specializes in creating ortho implants using 3d printing technology.

Metal 3D printing (Additive Manufacturing) is the most recent manufacturing technology and 3d printing in healthcare has the potential to transform the way the healthcare industry works. With 3d printing, we are capable of producing complicated and elaborate shapes without using tools and in much reduced time. We use the 'Near Net Shape' manufacturing technique, which is required in 3d printing medical applications.

Why Choose 3D Incredible

Benefits of Metal 3D Printing

at low cost

lead time

Optimisation

Development

Engineered parts

Management

Process Flow

Testimonials from Our Doctors

This is to certify that, I have used customized cranial implant printed with Additive manufacturing technology by 3D Incredible Private Limited. It has served the purpose in terms of Precision, quality of the implant and patient’s satisfaction.

Dr. Nikhil Talathi

M.Ch. (Nurosurgery), M.R.C.S. (Eng.)

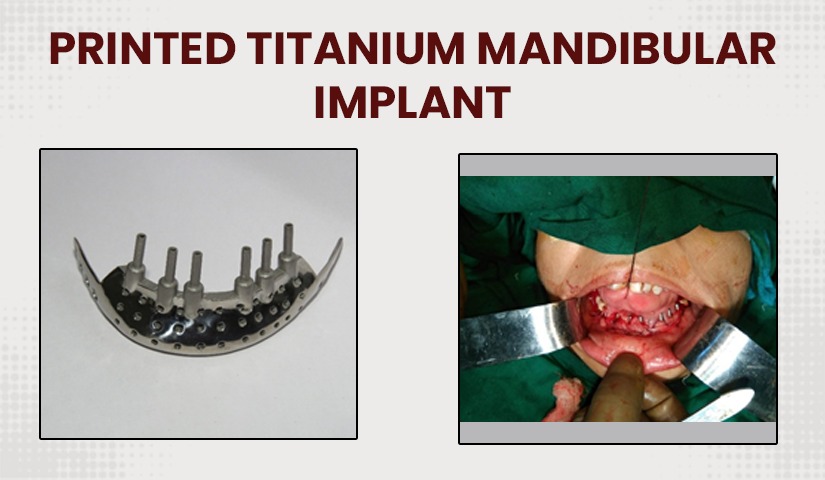

I have used 3D Titanium (Confidence) mid-face implants for reconstruction. I have found it very comfortable while placing the implant and the customization done by company is excellent. Hoping for further endeavour.

Dr. M. M. Vijapur

Cunsulting Oral and Maxillofacial Surgeon

This is to clerify that I have recently used a 3D Printed titanium cranioplasty implant for a petient who had a large cranical defect as a result of decompressive craniotomy following a new stroke This young boy after the operation showed remarkable improvement in his appearance. The 3D implant was prepared by the 3D Incredible Company.

Dr. Dilip Kiyawat

I have used Titanium 3D Printed (Ultifit) implants for cranioplasty from Incredible AM Pvt. Ltd. Pune. I found it very easy to manoeuver during surgery fitting was excellent and self tapping screws provided worked very well. Big size (14 cmx 12 cm) implant could be fitted in 40 minutes skin to skin. it is patient friendly also inert and fitting exactly over the defect. I am very happy with the implant.

Dr. Vinayak Joshi

Neuro Surgeon

Our Videos

Case Studies

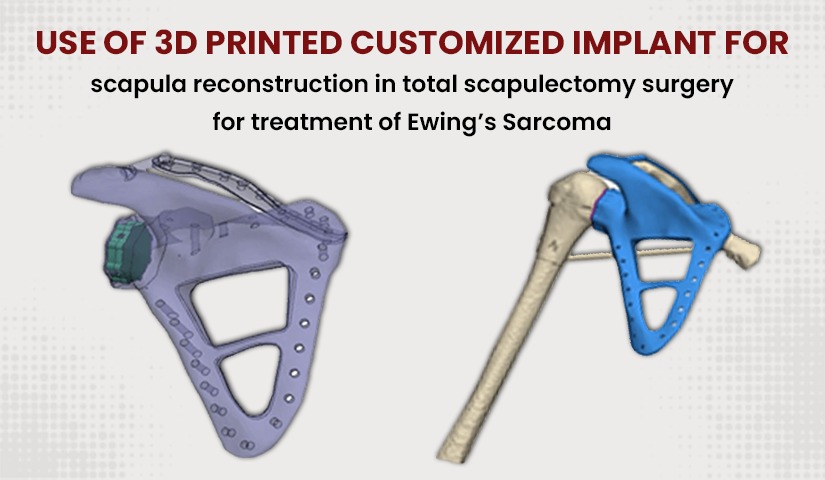

Use of 3D printed customized implant for scapulare construction mized Jigs and Implant for Internal Hemipelvectomy in Spindle Cell Sarcoma

Name of the surgeon : Dr. Ravi Sauhta

Place : Artemis Hospital, Haryana

Surface finish : Matt finished

Material : Patient specific anatomy model,patient specific scapula implant

Read more

3D Printed Customized Jigs and Implant for Internal Hemipelvectomy in Spindle Cell Sarcoma

Name of the surgeon : Dr. Hameed Abdulla

Place : Tanjawar, Mumbai

Surface finish : Mirror finished surface & matt finished abutments & Internal Extensions

Read more

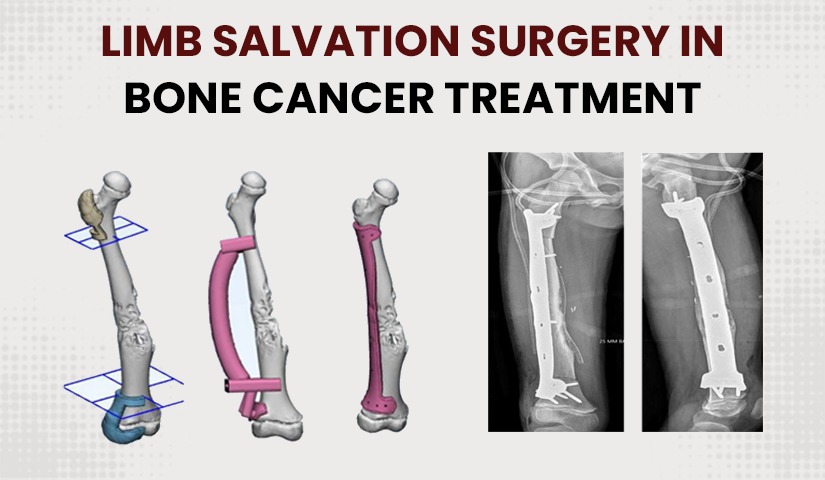

Limb Salvation Surgery in Bone Cancer Treatment

Name of the surgeon : Dr. Manish Agarwal

Place : P. D. Hinduja Hospital, Mahim, Mumbai

Implant size : 55.06*44.34*220.3223

Surface finish : Matt finished both side

Material: Patient specific anatomy model, customized bone resection jigs, patient specific implant

Read more

Contact Us

Plant Address

Gat No. 699/1, Koregaon Bhima,

Behind Kalyani Forge, Tal- Shirur,

Dist- Pune 412 216,

Maharashtra, India.

Mob No: +912047149879

Pune Office Address

SR No 221, Plot No 21, MIT Residency, Ground floor,Below Kashish Arts, Lane No 3B, Kalyani Nagar ,Pune – 411006Maharashtra, India.

+91 7030940790 (Engineering)+91 7030952720 (Medical)

info@3dincredible.com