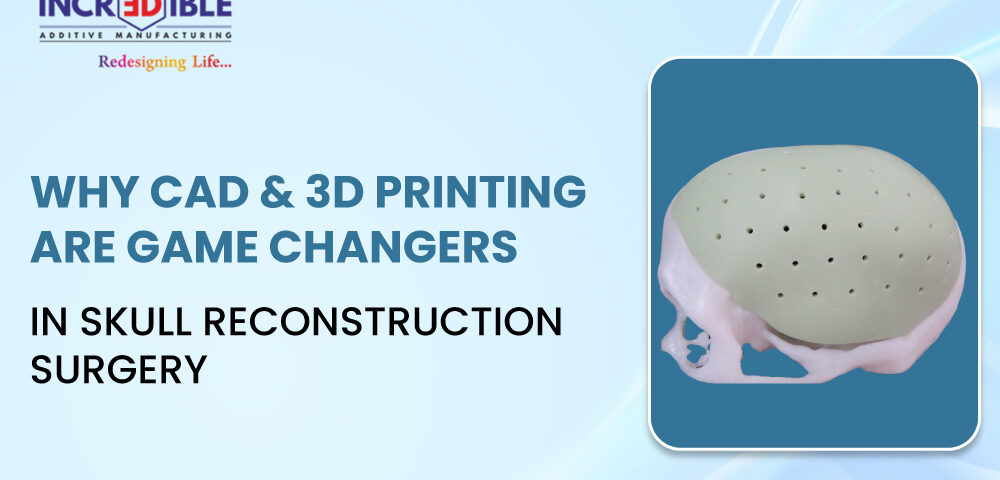

The practice of skull reconstruction has, in the past, used hand processes with the standard implants that have prolonged recovery periods and rough outputs. However, the use of CAD and 3D printers has transformed this area in a way that now surgeons can plan and conduct highly personalized operations. The fact that 3D printing services can allow designing implants compatible with a patient’s specific anatomy helps to increase the surgical accuracy and the recovery rate of a patient after a surgical process. Besides improving medical outcomes, this strategy also helps to cut down the time in surgery itself and is thus a game changer in the field of modern craniofacial reconstruction.

Customized implants result in better surgical outcomes

Among the most revolutionary applications of CAD and 3D printing in skull reconstruction surgery, making patient-specific implants is one of the most significant. The accuracy brings better bone integration and fewer complications after the surgery. The patients have the benefit of faster recovery and an improved level of satisfaction, whereas the surgeons can conduct the surgeries more confidently and expediently.

Minimally invasive solutions with higher accuracy and better aesthetics

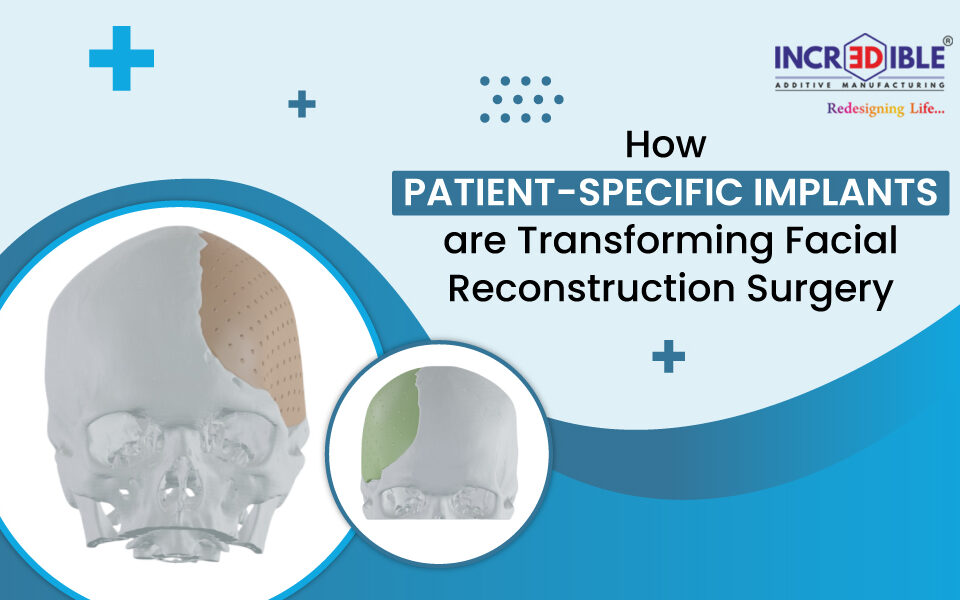

3D printed cranioplasty makes the production of the implants that are not only anatomically accurate but also less bulky, meaning that there is minimal invasion on the body. The possibility of designing implants that can harmonize with a patient’s natural contours creates better cosmetic results. This is particularly important in facial reconstructive surgeries, where both function and appearance are important. The technology enables superior symmetry and a natural appearance that attests to confidence and quality of life following the surgery.

How does 3D printing improve patient recovery and satisfaction?

Measures of post-skull reconstruction recovery are usually difficult, and having 3D Printing a cranial implant makes this process more expedient. With perfect anatomical skewing and biocompatible materials, the body accommodates well to the implant well, an effect that minimizes inflammations and postoperative complications. Consequently, hospitalization periods are reduced, and the cases of revisional surgery are reduced. The personalized fit and the improved cosmetic result lead to a more satisfied patient, and with that, 3D printing is a patient-friendly option in modern cranial procedures.

What is it that makes CAD-3D printing the future of skull surgery?

The accuracy, efficacy, and patient-specific benefits that arise from the use of CAD and 3D printing have created a new benchmark in skull reconstruction. Surgeons are now able to deal with complex cases with higher levels of precision and predictability. The transition toward digital fabrication from the traditional practice is fueled by the consistent achievement of success in the clinical outcome and improved surgical abilities. Furthermore, as technology advances and the availability increases, more healthcare centers implement this approach. Its capability to provide individual, specific solutions to real surgical obstacles not only proves it to be a trend but also a future-safe practice in the field of cranial surgery.

Conclusion

CAD and 3D printing services have indeed transformed the way skull reconstruction is addressed with so much accuracy, personalization, and faster healing than ever. From improved implant fit and improved aesthetic results to shorter surgeries and greater patient satisfaction, the advantages are obvious. With the increase in availability and adoption rate of the technology, it is revolutionizing the care of patients in craniofacial surgery. At the front line of this innovation is 3D Medical, bridging the gap between state-of-the-art digital design and a life-changing surgical outcome.