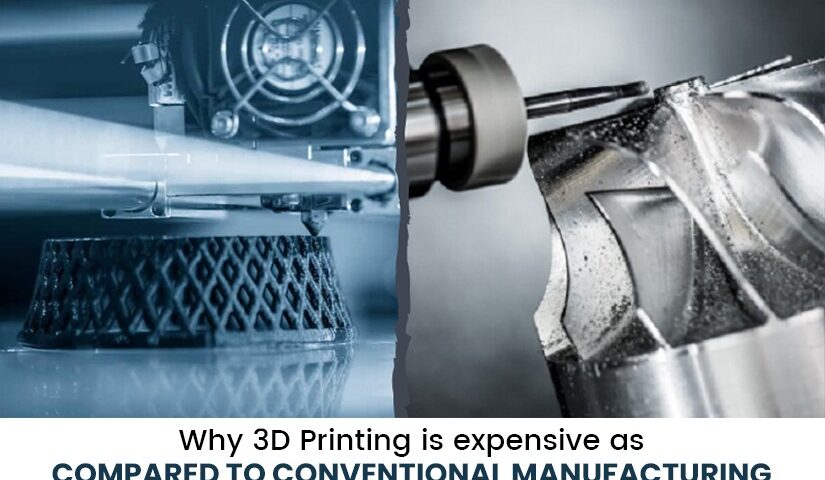

Additive manufacturing or commonly known as the 3d printing technique is an industrial computer-based manufacturing technique that deposits materials layer by layer to create 3D objects. The primary component of this technique is the combination of components to produce a new item. It is the latest manufacturing technique and a promising one. Though the technique is majorly used for prototyping and is suitable for batch production/custom designs, it has still not replaced conventional manufacturing methods. This is because the latest manufacturing technique has some limitations, and the cost of 3d printed parts is one of them. In this blog, let us know what makes 3d printing more expensive than conventional manufacturing.

What makes 3d printing expensive?

Several factors make 3d printing expensive. These include:

Machine and tooling costs

The initial investment in manufacturing machinery is, by far, the biggest cost driver in additive manufacturing. According to a recent study by the National Institute of Standards and Technology (NIST), initial machine expenditures make up between 45 and 74% of the overall cost to create a product additively. The initial investment in machines represents the biggest contributor to the cost of additive manufacturing since precision additive manufacturing equipment may be fairly expensive to buy and install.

A slow process

In 3D printing, the material is added layer by layer, which is time-consuming as compared to conventional manufacturing, where the material is subtracted. So, producing high-volume of parts with additive manufacturing will be too expensive.

Material cost

Compared to metal ingots or plastic for injection moulding, the material used in additive manufacturing procedures can be much more expensive. Materials for additive manufacturing can cost up to eight times more per unit of weight than conventional materials.

Sometimes, some parts with overhanging, holes or edges need support for successful fabrication and to achieve desired features. These support structures need additional material, which leads to extra raw material costs.

However, raw materials account for only 18% to 30% of the total production costs on average in additive manufacturing, these costs are expected to decrease as more material options will be available for additive manufacturing.

Post-processing

Also, there are various post-processing operations involved, such as support removal, primary cleaning and finishing, wire EDM, heat treatment and bead blasting/buffing after creating a 3D printing part.

In some cases, high accuracy is required in the part, and for achieving the desired accuracy we need to perform machining operation post-printing, which leads to additional cost.

Additionally, other factors like part orientation also affect the 3D printing cost. Parts with long length/height needs more printing time, as compared to small parts, and hence machine running cost goes high.

Conclusion

The above factors make 3d printing expensive as compared to traditional manufacturing methods. However, the technique is best for prototyping, batch production and custom design, since it does not require extra tooling and helps in fast iteration.

Incredible AM Pvt Ltd, located in Pune, is one of the first establishments to offer 3d printed products and services. Here, we collaborate with a group of knowledgeable and experienced Leaders, Engineers, and Doctors to make the vision a reality. Our cutting-edge facility has all the tools required to offer the best solutions to various industries at the lowest cost, greatest quality, and quickest lead times.

To get the best quality 3d printed products and services, feel free to connect with us.