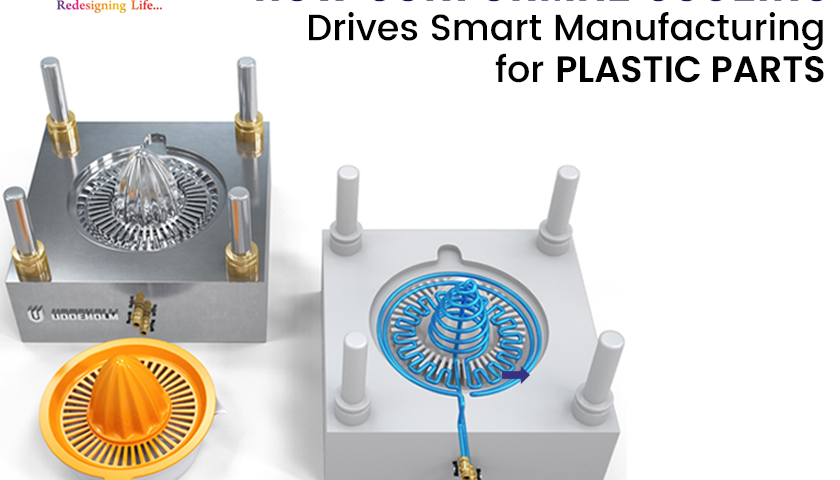

How Conformal Cooling Drives Smart Manufacturing for Plastic Parts

Innovation is crucial in reshaping traditional manufacturing processes to provide more effective and efficient manufacturing methods to make objects. Conformal cooling is one of the most advanced manufacturing methods of plastic parts. Industries have several advantages of incorporating conformal cooling into their production processes. These include increased productivity, sustainability, and better part quality. This article explores how conformal cooling helps in the smart production of plastic components.

What is Conformal Cooling?

In plastic injection, cooling systems are built with consistent, straight channels. Though these systems work efficiently, they often cause uneven cooling. It causes completed items to have flaws such as warping, sink marks, and residual tensions. Conversely, conformal cooling entails the formation of cooling channels that follow the contours of the component being produced. These channels provide consistent cooling and enhance part quality by following the mould’s curves.

How Does Conformal Cooling Enable Smart Manufacturing?

Enhanced Part Quality

Conformal cooling lessens the possibility of flaws like warping and shrinking by ensuring consistent cooling throughout the whole surface of the component. As a result, the items constantly fulfil high-quality standards and have better surface finish and dimensional accuracy.

Enhanced Productivity

Conformal cooling speeds up production rates by reducing cycle times and optimising cooling efficiency. Reduced cycle times allow for the production of more parts in a shorter amount of time, increasing throughput and overall productivity.

Cost Savings

Over time, conformal cooling’s enhanced part quality and shortened cycle resulted in considerable cost savings. With less material wastage, energy usage, and maintenance expenses, businesses can eventually increase their bottom line.

Design Freedom

New opportunities in part design are made possible by conformal cooling. Engineers can create better plastic parts by utilising complicated features and complex geometries without compromising cooling efficiency.

Sustainability

Conformal cooling helps to promote a more environmentally friendly method of production by streamlining the manufacturing process and cutting waste. Businesses may satisfy the growing demand for environmentally friendly manufacturing methods while reducing their environmental impact.

Applications of Conformal Cooling in the Manufacturing of Plastic Parts

Automotive Parts

Conformal cooling has changed how vehicle parts, like intricate engine parts and interior trim, are produced. Manufacturers may remain cost-effective while meeting the demanding standards of the automobile industry by decreasing cycle times and increasing part quality.

Medical Devices

Conformal cooling is essential in producing high-quality plastic components for medical devices in the medical industry, where accuracy and uniformity are critical. Medical devices are reliable and safe because of conformal cooling used in making syringes, surgical equipment, etc.

Consumer Electronics

Complex plastic parts utilised in consumer electronics, such as computer components and smartphone cases, may be produced thanks to conformal cooling. Achieving outstanding part quality and design flexibility is critical to satisfying the ever-evolving demands of the electronics industry.

Conclusion

Conformal cooling is a paradigm shift in plastic part manufacturing that promotes intelligent manufacturing techniques that improve sustainability, productivity, and quality. Businesses may produce better products and stay ahead of the competition by adopting this advanced technology and streamlining their processes.

Incredible AM Pvt Ltd in Pune is a pioneer in 3D printing in India. We have an experienced team and a world-class manufacturing facility that helps in the manufacturing of efficient plastic parts with conformal cooling.