Why Additive Manufacturing is Revolutionizing the Automotive Sector

Additive manufacturing is also known as 3D printing and is one example of developed technologies that is gaining use across the globe. It has turned out to be a transformative solution in different sectors, and the automobile industry is no different. This technology has made its way to different possibilities in production, design, and even performance in the automobile world. In the automotive sector, it has turned out to be a game changer in many ways. With its help, the designer can create incredible prototypes be it creating simple elements of the interior or scaling the model of the whole car at a faster pace. Here’s what makes 3D printing in the automotive sector a revolutionary change.

Transforming car designs and parts

Additive Manufacturing in India is in demand as it accelerates development while enhancing the creation of prototypes. It allows the new parts production which was not possible with traditional manufacturing methods. 3D printing allows vehicle manufacturers to create models, tools, and even small batches of parts on-site. This allows engineers and designers to work more effectively, test their ideas more thoroughly, and feel more confident in the production process.

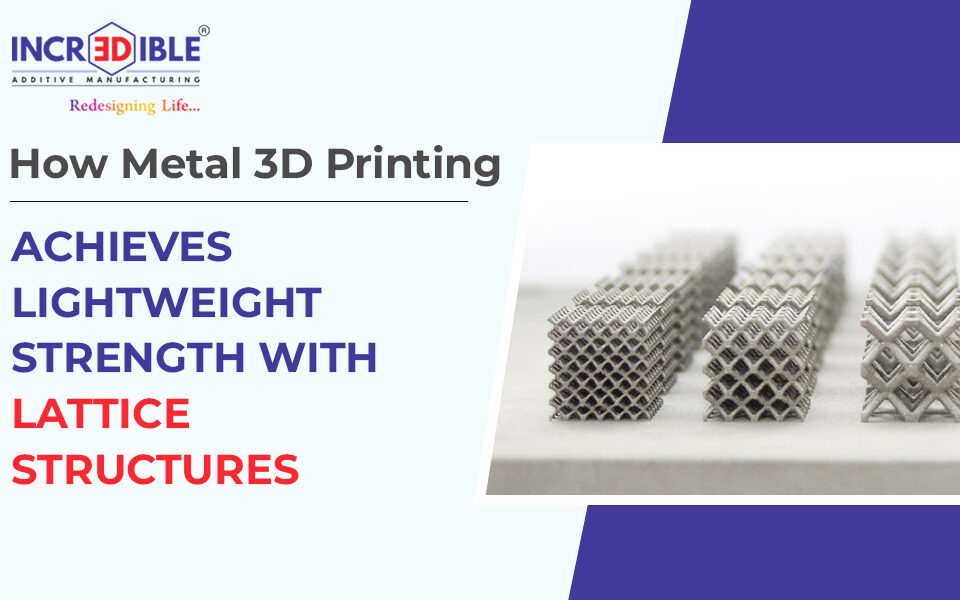

Freedom to Design with Flexibility

It is not just the new designs but also the freedom it offers the designers to create the pattern of the car is amazing. 3D printing in the automotive sector offers flexibility to design that lets engineers even create the most complex geometrics conveniently with a lightweight structure. Earlier with traditional manufacturing ways, it was quite challenging. But with the present technology development, the design freedom enhances the performance of the vehicle with better efficiency of the fuel.

Progress in electric mobility

The concept of electric vehicles has gained massive interest, especially after the introduction of Additive Manufacturing in India. Electric vehicles are quite an environmentally friendly way of transportation as compared to traditional vehicles. Even if there had been certain progress made in the present time to reduce the battery weight for electric vehicles it still is the heavy component. With more weight, there is likely to be an effect on overall vehicle performance. Engineers have always been considering ways to lessen down the individual parts weight when creating the vehicle components. The good part is additive manufacturing has made it possible to create parts using unique geometrics. This way engineers can create even those parts that were not available with traditional technologies.

Better Supply Chain with Less Waste Reduction:

3D printing, also known as additive manufacturing, can greatly improve the car supply chain. By making parts on-site or at smaller local hubs, car companies don’t need as much warehouse space or long-distance transportation. This not only saves money but also makes the supply chain stronger and more flexible Traditional manufacturing sometimes requires producing huge quantities of things at once, which can result in excess inventory and waste. Companies can use additive manufacturing or 3D printing to make parts only as needed. Such production eliminates the requirement for excess inventory while also lowering waste and expenditures.

Conclusion:

Certainly, 3D printing in the automotive sector has brought a better change in the present era of the automobile industry. It has been impactful, and the technology is likely to get advanced every day which will shape the future of vehicle design and customization. There are certainly high chances for 3D printing to further integrate into the automotive sector and if you want to enjoy more of its benefits then you can opt for Incredible AM Pvt. Ltd which has been providing this novel technology.