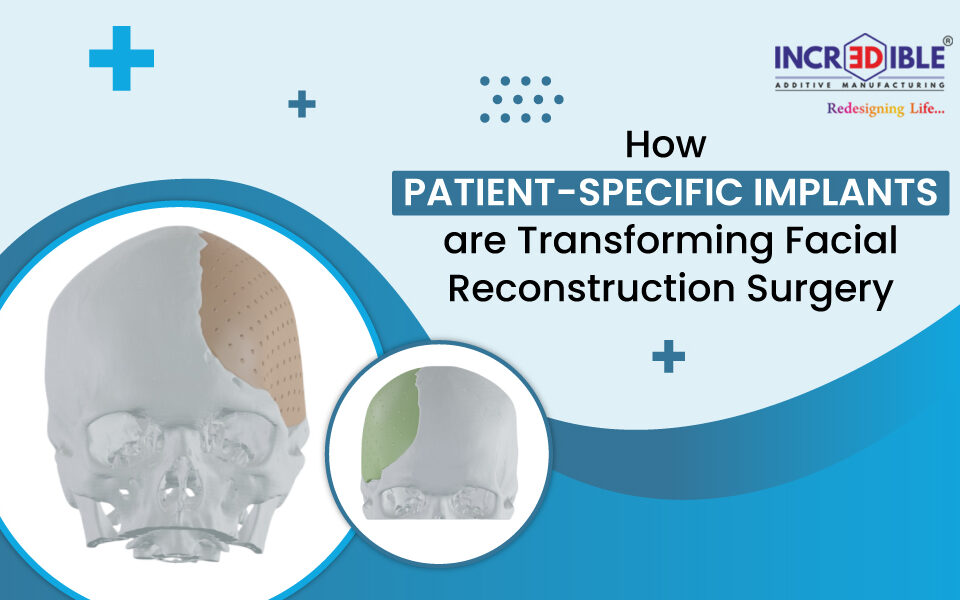

Technology has advanced greatly, and 3D printing has become a crucial part of medical history. One popular application is in mandible implants, which utilize 3D printing technology. These implants focus on healing injuries related to complex facial structures. Treating facial injuries requires expert guidance, and mandible implants enable smooth reconstruction while retaining functionality.

Facial injuries often result from cancer, accidents, or malformations, increasing complexity and requiring high accuracy in treatment. Additive manufacturing, or 3D printing, is used in such surgeries to create new jaws that promote faster recovery and match the patient’s anatomy. Mandibular implants with 3D printing help surgeons understand how to replace bone defects, eliminating the need for autologous bone grafts.

How 3D Printed Mandible Implants Make a Difference

Better Aesthetics:

One primary advantage of 3D-printed mandible implants is improved aesthetics. Traditional reconstruction methods often result in facial disfigurement and visible scars, which can affect a patient’s mental well-being. With mandible implants, there is greater potential to restore the original facial structure, boosting patient confidence and leading to a healthier life.

Perfect Fit:

Customization is possible with mandible implants using 3D printing technology. A properly fitted implant allows patients to regain normal jaw movement without difficulty, facilitating easier eating and chewing. This is a significant achievement in the field of jaw reconstruction.

Quicker Recovery:

Using patient-specific implants improves the accuracy of jawbone repair, minimizing the need for additional surgeries or bone grafts. Custom 3D-printed implants reduce recovery time by eliminating complications like swelling and inflammation.

Biocompatible Materials:

Research indicates that not all patients tolerate metal-based implants equally. Metals like nickel and chromium can cause allergic reactions in some patients. Titanium (Ti6Al4V-ELI Grade-23), used in mandible implants, is biocompatible and does not corrode in bodily fluids, offering a durable solution with fewer complications.

Reduced Operation Time:

Compared to traditional surgeries that require extensive manual shaping of implants, 3D-printed mandible implants streamline the process. This reduces surgical time, hospital stays, and critical care needs, enabling faster recovery for patients.

Conclusion:

Since the introduction of 3D-printed mandible implants, patients with jaw injuries and tumours have benefited from simpler treatment options. The future holds promising advancements in this technology, further revolutionizing medical care. Companies like 3D Incredible Medical are at the forefront of integrating advanced technology into complex treatments, ensuring precise results and improved patient outcomes.