Trauma and neurosurgical procedures like decompressed craniotomy, tumor resections, infections, and congenital defects are the most common causes of cranial defects. Protecting the underlying brain tissue, lowering any localized pain and patient anxiety, and enhancing cranial aesthetics are the goals of cranial vault repair. With the help of cranial prostheses made of materials like titanium, autologous bone, ceramics, and polymers, cranioplasty is a common neurosurgical procedure. The creation of implants frequently involves expensive intraoperative procedures. In contrast to other conventional techniques, implant-customized manufacturing for ciliopathies enables precise anatomical reconstruction in a faster surgical procedure. We offer a straightforward, affordable approach to implant production that guarantees surgical success.

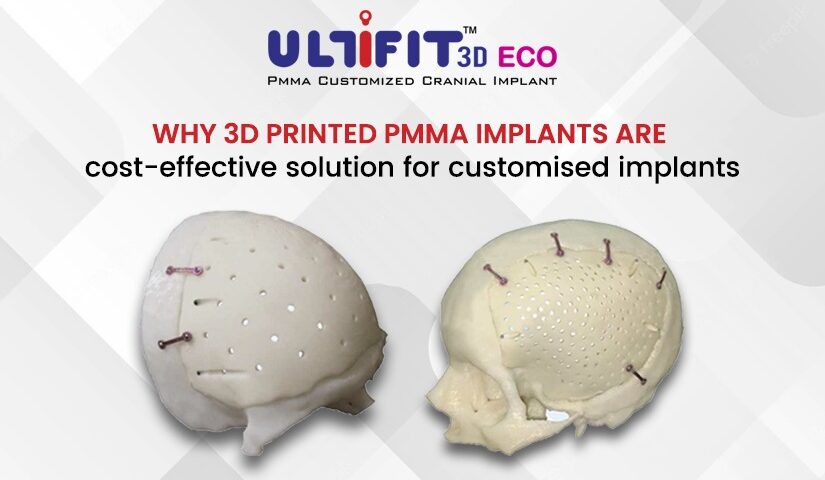

3D printed customized implants made using PMMA

For cranial reconstruction, we create 3d printed cranial implants. A 3d computed tomography is used to design and create a digital implant model. A 3D printer is used to create a physical model from the data of large cranial defects and implants. This model is then used in a lab to create the final, customized implants out of polymethyl methacrylate (PMMA).

PMMA, a cost-effective solution for creating customized implants

PMMA (poly methyl methacrylate) also referred to as acrylic and Plexiglas has earned the medical term “bone cement” due to its biocompatibility. This lightweight, inexpensive, adaptable material is also used in the medical field for bone implants, dentures, and other things.

Despite being created by polymerizing the irritant and potential carcinogen methyl methacrylate (MMA), PMMA is very biocompatible. PMMA is resistant to temperature stress, chemical reactions, human tissues, and bioprocesses and this makes it a fine biocompatible material.

Using PMMA for creating customized cranial implants, generally, no complications occur. Issues such as changes in rejection, toxicity, local or systemic infection, and appearance were all significant and satisfying. A customized 3D PMMA implant is more affordable, produces excellent aesthetic results, requires less time to operate, and is more biocompatible.

But from where can you get cost-effective customized implants?

Incredible AM Pvt Ltd of Pune, India’s first ISO 13485 and ISO 9001 certified company for manufacturing 3d printed customized implants, is the one-stop solution for all 3d printed medical implants, bio models, and surgery tools.

Incredible, the best manufacturer of cost-effective 3d printed implants

Incredible understands every patient has their requirement and needs personalized treatment as no two individuals have the same anatomy therefore it provides custom-made cranial implants that exactly fit an individual’s anatomy.

At its world-class manufacturing unit, Incredible has the latest and most advanced to provide a specific and accurate solution for additive manufacturing technology and utilizes USFDA and CE-approved licensed software, such as Materialise Mimics, 3Matics, Magic, Quant AM, and NX-Siemens to accomplish the complex task.

In addition, our medical device manufacturing performs in 10,000 cleanrooms and conducts validation/calibration of equipment on a regular basis through NABL accredited laboratory ensuring the quality of the product.

Above all, we have a team of skilled professionals, including engineers, designers, biomedical engineers, and doctors, who work together to create customized, high-quality 3d-printed cranial implants that completely satisfy our customers.

To end with

3D Incredible, with an experience of over 40 years, is the best manufacturer of cost-effective, customized cranial implants that provide the best aesthetic and functionality to the disfigured skull of the patient.

If you need cost-effective PMMA customized implants, connect with us.