The global additive manufacturing industry has developed very rapidly offering wider and high value applications. This speedy shift has been due to its advantages over conventional manufacturing.

Today, applications of additive manufacturing seem to nearly limitless. It is used to manufacture high-tech industrial (aerospace, medical/dental, automotive, electronic), consumer (home, fashion, and entertainment) products.

3D Incredible is a metal 3D printing service provider having advanced equipment. 3D Incredible is one shop stop solution provider who can assist customers regarding design, 3D printing to post-processing operations.

Team of Experience Engineers & medical Experts

3D Incredible originated from IMP manufacturer who has over than 48 years of trusted experience in manufacturing the unsurpassable quality product. The engineering staff at 3D Incredible have been involved in the industry form 2017. 3D Incredible pride ourselves on our updated training, skills, and experience related to the Advanced Manufacturing community.

World Class State-of-the-art Manufacturing Setup ISO 13485 and 9001 Approved facility

Regulatory requirements are increasingly stringent all over medical industry, including service and delivery. Increasingly, organizations in the industry are anticipated to determine their quality management processes and ensure best practice in everything they do. 3D Incredibles has fulfilled this internationally approved standard for a quality management system specific to the medical devices industry.

Ultra-modern Software Designing Lab

3D Incredible work in hand with the largest group of skilled and experienced Biomedical engineers, doctors, mechanical engineers who turn the vision into reality. Our modern laboratory design emphasizes features that enable flexibility for higher work efficiency, and sustainability as well. “Incredible AM Pvt. Ltd aka 3D Incredible is an Additive manufacturing (3D metal printing) company which deals in Selective Laser Melting process, capable of producing fully dense metal implants, direct from 3D CAD model using a high-powered fiber laser, by fine metal powders that are fully melted in a tightly controlled atmosphere, layer by layer

Quick turnaround Time

Additive manufacturing facilities today are more focused on offering services that are reliable and easily available. For product development, additive manufacturing increases speed-to-market and simplifies the multi-stage prototyping processes. The technology makes it possible to create samples in hours, rather than days or weeks. Hence, keeping time and quality on priority, our center is working towards reaching our goal of meeting 100% stated requirement of Customer and to provide 100% supply on time. While a few manufacturers emphasize more on error reduction with a slow process, Turnaround time (TAT) is a crucial aspect that defines the throughput, pricing and customer satisfaction.

Competitive Pricing

In comparison to traditional manufacturing processes, additive manufacturing reduces capital investments and volume requirements for a product line. This enables medical implant manufacturers to produce a broader assortment of products without adding overhead from extra product lines or more set-up time from switching between low-volume products. Additionally, additive manufacturing significantly reduces material waste inherent in traditional manufacturing processes, reducing 3D Incredible’s product-prices, to offset industry-wide cost cutting pressures in healthcare.

Products:

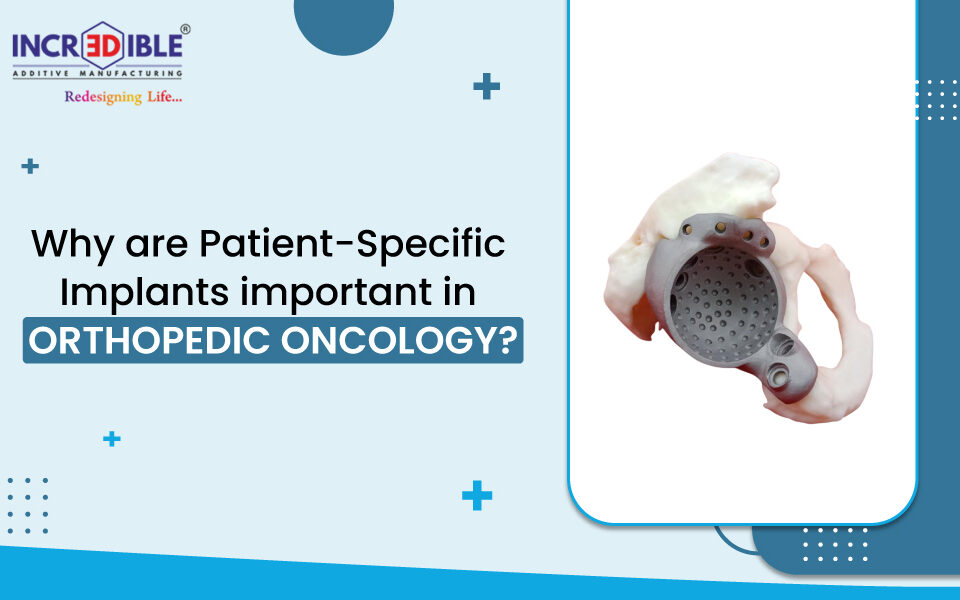

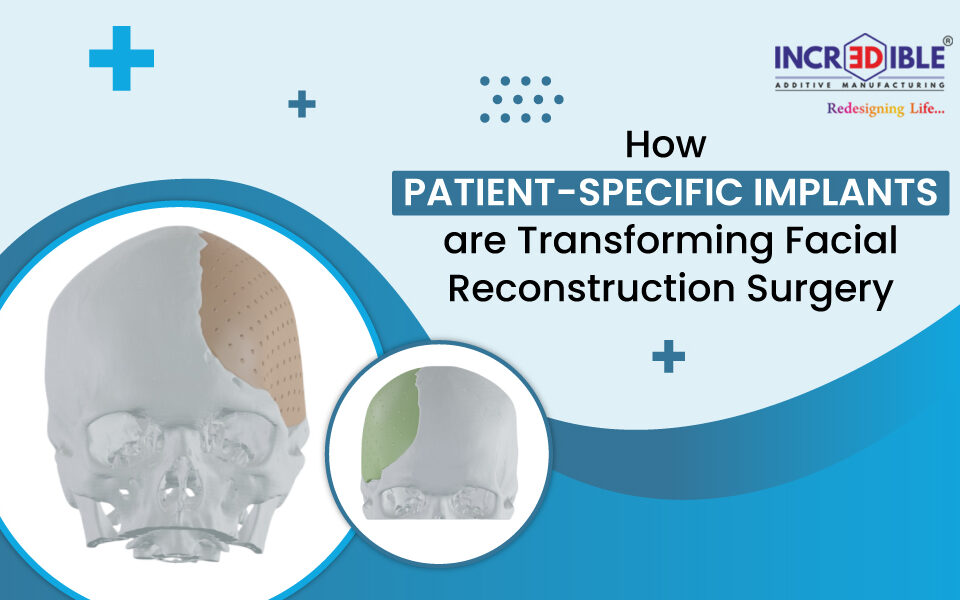

3D Incredible offers world-class precision products that are a perfect fit to the requirement, like the cranial implants. They are required to restore the skull contour, 3D printed patient Specific cranial implant helps in providing exact symmetry & maintain original aesthetics.

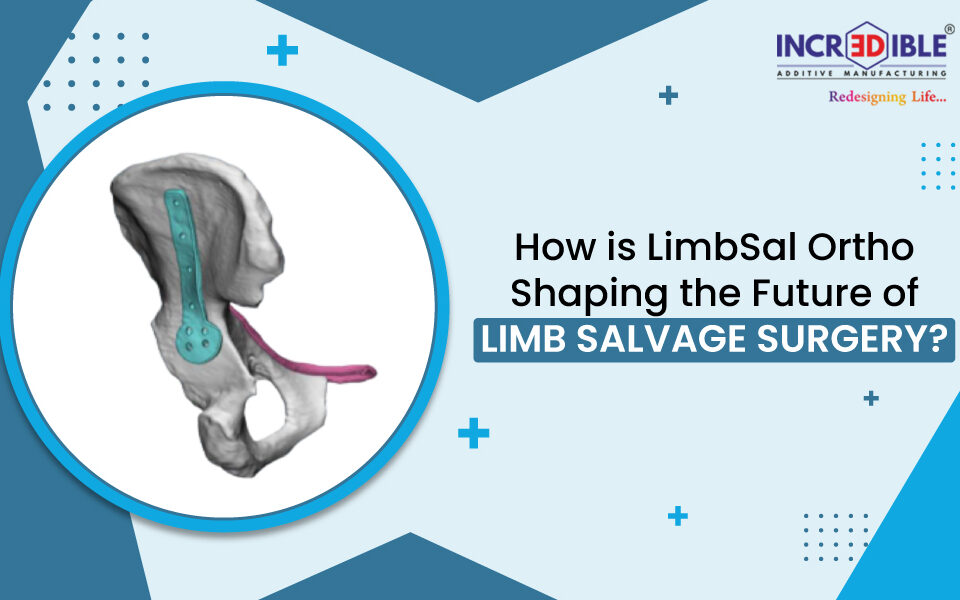

A 3D Incredible product like LimbSal Ortho is a 3D printed customized implant and needs high precision in designing. 3D incredible with its high-quality additive manufacturing has been able to produce on the best patient specific implants.

Conclusion:

Not only implants but 3D Incredible also manufactures patient specific anatomy models. It is available in material of choice as per indication and requirement like PLA, ABS, Nylon, Sandstone, silicon and proves an excellent tool to study and pre-surgical planning.

3D Incredible additive manufacturing thus offers a wide range of products, and all the products offered by 3D Incredible are with excellent detailing. The product range is completely patient friendly as it maintains all required features like low thermal conductivity, high corrosion resistance, high strength to weight ratio and biocompatible material