Additive Manufacturing is the potentially disruptive manufacturing technology in which a structural component is fabricated layer by layer via digital information. Fabricating structural components layer by layer from digital information provides the benefits of increased design freedom, including the ability to exploit the results of topology optimization algorithms to significantly lightweight parts, eliminating system part count by consolidating assemblies into fewer parts, reducing the lifecycle time between concept, design, manufacture, and validated component delivery, a buy-to-fly ratio that approaches unity thereby leading to significant raw material cost savings. AM also has the ability to incorporate added functionality, such as internal cooling channels and thermowells into components; manufacture highly complex geometries that would be impossible or very difficult to be realized with traditional methods.

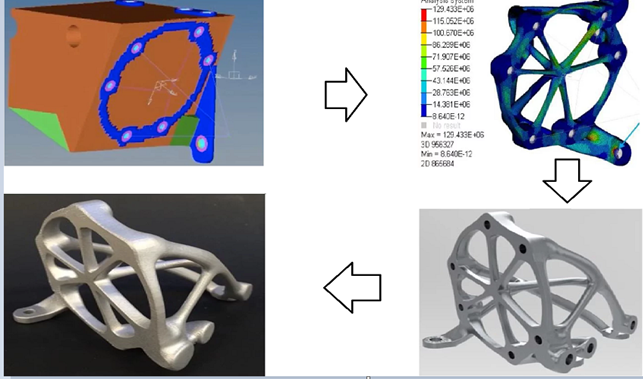

Process Flow for the fabrication of AM components

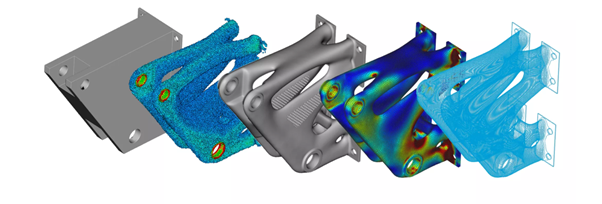

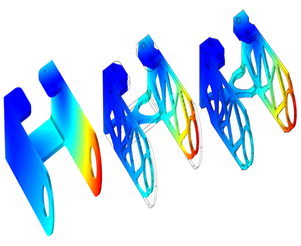

Topology optimization makes the lightweight parts without compromising their strength. Topology optimization can help to produce parts with enhanced performance and mechanical properties. It is a technique that optimises the geometry of an object using mathematical calculations. Using topology optimization software, designers can optimise the material distribution in specific places as the software tool analyses the stresses on the shape and removes any unnecessary material from the design. Which areas of the part are to be optimised is based on several requirements, such as load, deformation, stiffness constraints and boundary conditions. In other words, topology optimization helps to create the best possible structure of a given part.

The benefits of topology optimization

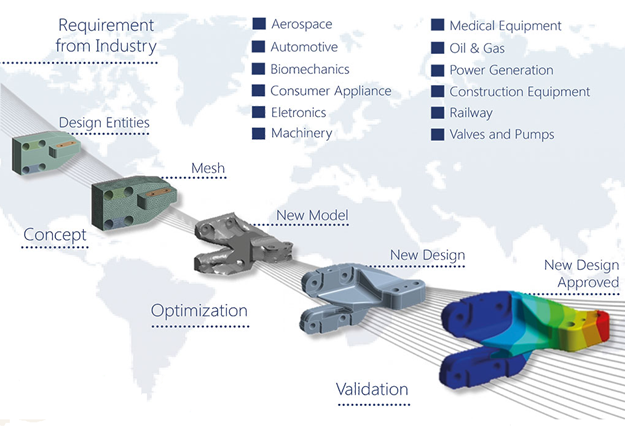

Topology optimization pushes the boundaries of design freedom even further, offering a range of benefits and opportunities for additive manufacturing in the most demanding industries. Additionally, topology optimization tools enable the ability to maximise thickness in the areas that need it most, as well as reduce the mass of a part by removing the material in areas that are not exposed to boundary loads. Aerospace is one of the top adopters of topologically optimised designs, thanks to the benefits of creating lightweight parts, reduced support structures and preserved strength of the parts produced. Optimised and additively manufactured components prove to be highly valuable in cutting down costs for launching satellites and space vehicles. A good example is that of aerostructure manufacturer STELIA Aerospace, which has used topology optimisation to produce aeroplane fuselage panels with enhanced stability. There is also an added ecological benefit, with the topology-optimised design leading to less material waste. Since topology optimization allows additional features such as pore diameter, density, and mechanical properties to be incorporated in specific areas of the engineered component, it is now possible to create functional parts with optimal weight and mechanical properties.

Steps involved in the topology optimization of an engineering product

- Discretized domain is provided as the design space materials are defined:- For each element in the design space, the optimizer will attempt to find a density value that minimizes compliance (i.e., maximizes stiffness) while satisfying a simple volume constraint.

- Interpolation of data fields :- Interpreting the results of density-based topology optimization is where most software applications begin to divert from each other. Interpolation schemes are used to convert the element densities into continuous design variables better suited for optimization algorithms. This results in element densities that can range from 0 (no material) to 1 (solid material) but also vary in between.

- Geometry Reconstruction:- The geometry reconstruction problem is addressed by implicit modelling technology. With only a few inputs, an implicit geometric representation can be derived straight from a topology optimization result. Manual reconstruction of geometry after topology optimization is generally viewed as a major impediment. The resulting smooth geometry is generated in seconds and can immediately be used in downstream modelling, simulation, and manufacturing functions.

- Boundary conditions are applied for finite element model :- TA convergence study was not carried out in this work; however, the results are validated through a material test campaign that is the final step of the holistic process flow and is described in subsequent sections of this work.

- 5. Contour slices for manufacturing :- Slicing is an important step for all layer-based additive manufacturing (AM) processes. The improved and robust slicing algorithm with efficient contour construction can be used to reduce the slicing time and be able to slice a complex StereoLithography (STL) model with millions of triangle.

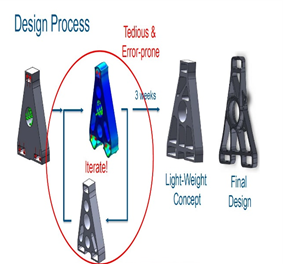

Process

Design Process

Design

Application of topology optimization

Topology optimization of camera star bracket

Summary

Topology optimization combined with Additive Manufacturing lead to fabrication of light weight complex part. It relocates the material within the design space and did not require the incorporation of the exterior boundaries into the design, thereby resulting in an organically shaped component that bears little resemblance to its heritage counterpart and it is significantly lighter in weight. Significant weight savings occurred in the topologically optimized version. Remarkable design freedom alongside enhanced functional performance are only a few of the advantages topology optimization software offers engineers and designers.