Technology and medicine are ever-growing fields. Fusing both of them is bringing a lot of innovative solutions for the betterment of patients. One of the newest and popularly used technologies in medicine is the 3D patient-specific implants (PSI).

The application of 3D printing has enabled and eased out many medical procedures for saving, enabling, and changing lives. 3D PSI can be significantly produced faster and has proved to be an effective solution. Without even sacrificing the quality it has uplifted the pace of the whole treatment, right from creating the 3D CAD models to the recovery process.

Fast Manufacturing

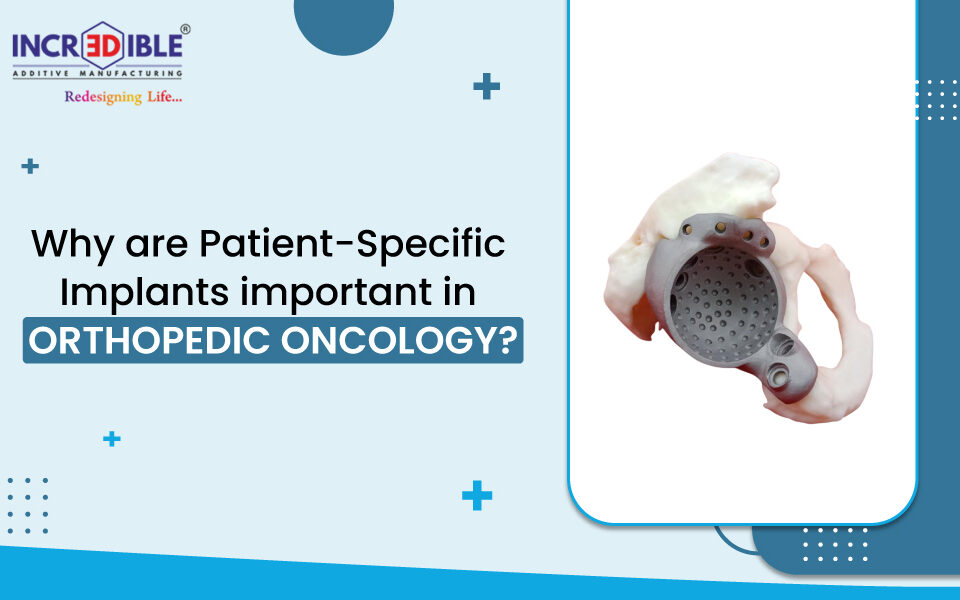

The traditional implant manufacturing process involved hand-manipulated layered biomaterial casting. There were higher chances of misjudgement and the cast had to be re-making again and again. Getting the right specifications to make the cast model was also really rare. This made the process really lengthy. But with the new technology doctors gets a 3D model to understand the exact anatomy of the patient and make the prototype accordingly.

The surgical guides have also even boosted the manufacturing process. These customized implants, prototypes, wheelchairs that can be produced according to the patient’s needs. The leading producer of 3D PSI, Incredible AM Pvt Ltd has a streamlined manufacturing set-up with 2 Renishaw AM 400 metal printers having a capacity of 400 W laser which has a build volume of 250 x 250 x 300 mm. Renishaw AM 400 is world’s best metal printing machine available currently to handle any complex tasks. Incredible AM Pvt. Ltd. have successfully completed over 300 surgeries in India.

Faster Operation

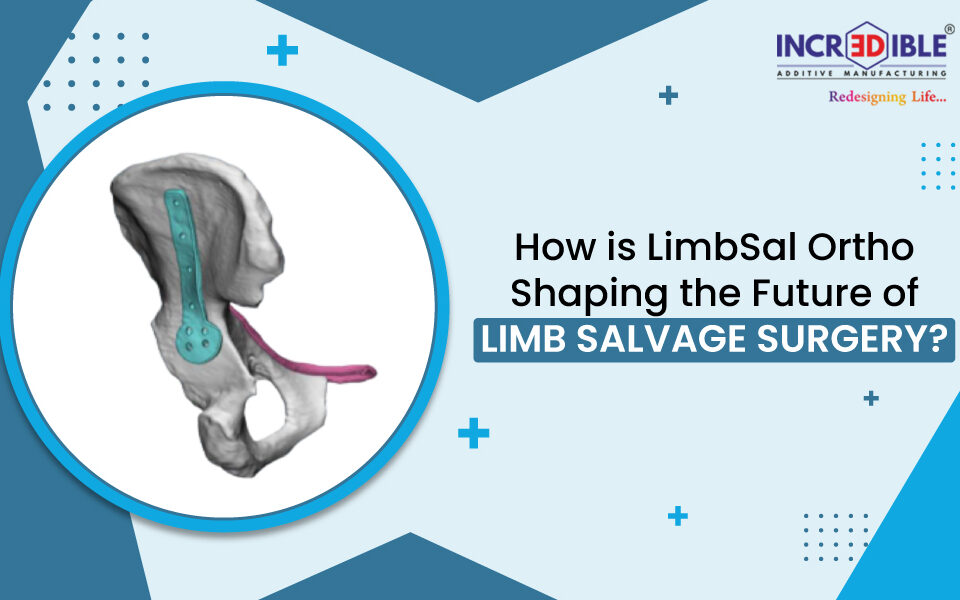

In the old manufacturing process fitting the customised implant was a big deal for the doctors and took multiple attempts as the only 2D image of the patient’s anatomy was available. It was hard for the doctor to gauge the right position of the patient’s anatomy. But with the 3D CAD models, doctors can pre-plan the operation and save the duration of surgery. Plus the surgeon takes fewer attempts to fit the implant saving the patient from further chances of post op infection.

The operation procedure takes less time as it allows skipping some steps and saves up the doctor’s time. In case of following the traditional procedures, the doctor has to perform a pre-op assessment on a patient and then visually inspect the placement of the implant. Plus the doctor has taken multiple attempts to adjust the implant properly. Opting for 3D technology gives you a high success rate. But the 3D PSI implants are long term solutions to the patient’s problems.

Fastest Recovery

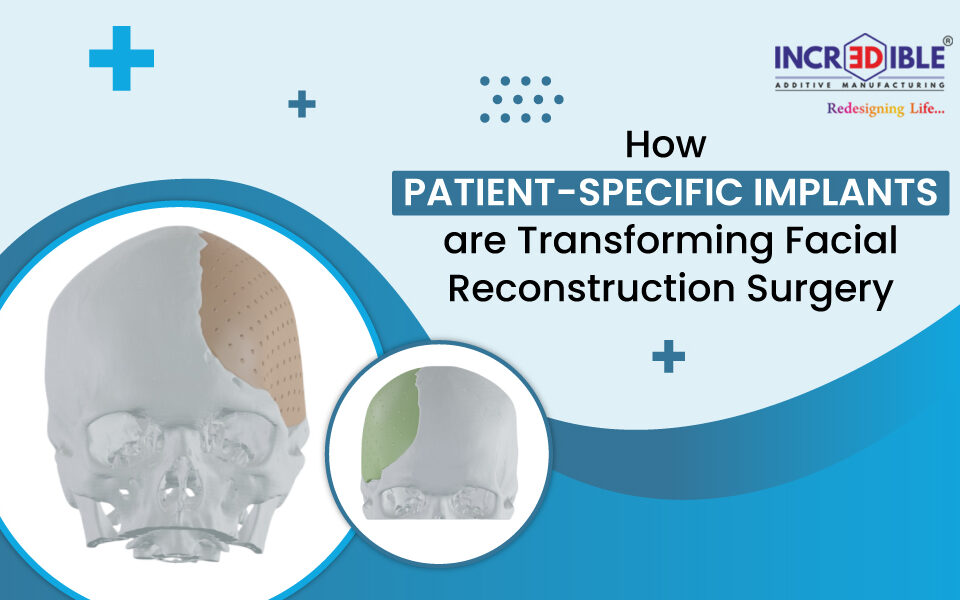

But the 3D PSI implants are so precise and made of biocompatible materials that it starts the functions soon.

The recovery process is the fastest as the operation causes less damage to the patients. The surgeons can attempt well-planned and meticulous surgeries. Because the implants fit properly doctors do not have to resect large bony tissues and soft tissue to fit implant perfectly. This helps the patient recover faster. 3D printed implants are coming with scaffold like structures called lattice results in faster osteointegration and fastest recovery.

Conclusion

Taking into account the growing demand and so many benefits of customized 3D PSI, Incredible AM Pvt Ltd, established in 2017 has been making groundbreaking innovations in the field. The flagship company Industrial Metal Powders (I) Pvt. Ltd. has been supplying its products to over 33 countries worldwide which has nutritional, Pharmaceuticals, Engineering, Chemical, Water Remediation, etc.

Incredible AM Pvt Ltd provides 3D PSI cranial reconstructions, maxillofacial implants, mandible implants, orthopaedics, anatomy models, as well as standard implants. These implants are a perfect fit, good aesthetics, low thermal connectivity, high corrosion resistance.