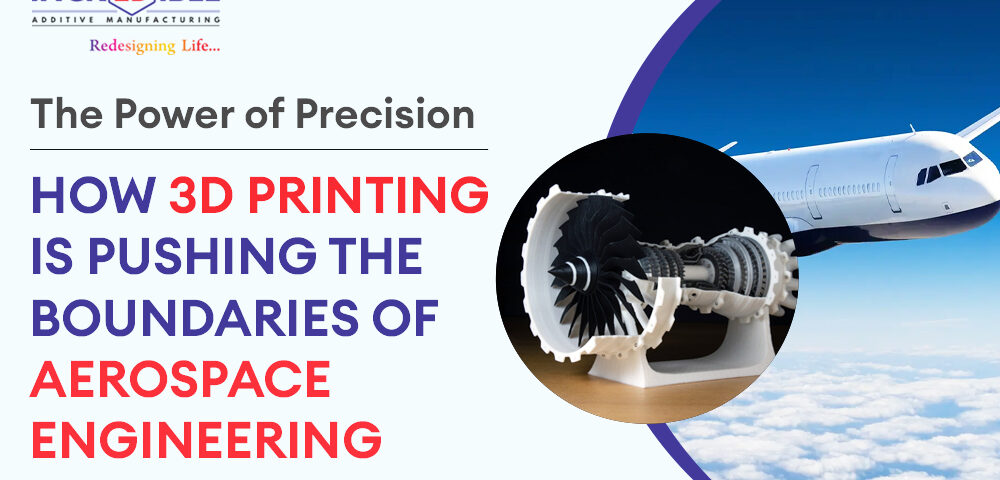

The Power of Precision: How 3D Printing is pushing the Boundaries of Aerospace Engineering

In the world of aerospace engineering, every gram matters and every detail counts. Additive manufacturing, under its name 3D printing, enables engineering practices with superior precision. 3D printing in aerospace utilizes a distinct approach over traditional manufacturing since it creates parts through consecutive layer additions. Organizations can now create groundbreaking designs together with slender components while quickening their manufacturing processes. The advanced technology helps aerospace companies create revolutionary production methods that extend aerospace possibilities both in airspace and in more distant realms.

Lightweight Components

Aerospace receives its most vital benefit from 3D printing through its manufacturing capability to produce strong but lightweight components. The weight reduction of aircraft components such as brackets structural frames and fuel nozzles can be achieved by engineers through 3D printing methods without sacrificing durability. The environmental advantages of using lighter aircraft result in reduced fuel use together with lower pollutant emissions that lead to enhanced sustainability performance. Weight-saving proves essential to 3D printing because it improves fuel efficiency while lowering emissions which means aircraft operate more economically.

Design Flexibility

Through 3D printing solution, engineers gain exclusive design independence to create complex designs that former manufacturing methods could not achieve. A single manufacturing operation enables the printing of sophisticated internal routes together with tailor-made cooling elements and integrated operational components. The manufacturing process now requires fewer assembled parts due to which the number of potential failures decreases which results in better system performance. Engineers achieve more creative freedom to innovate through design flexibility which permits them to meet industry-specific aerospace standards.

Cost-Effective Production

Elaborate production for both aged aircraft designs along with unique components results in significant expenditures and lengthy delays for part acquisition. The ability of Aerospace 3D printing helps aerospace companies convert their blueprints into digital format to make parts as needed which results in lower storage costs and reduced material consumption. Teams can lower expenses and shorten maintenance periods as well as support discontinued product lines more effortlessly through on-demand manufacturing.

Faster Prototyping

Aerospace development demands speed so 3D printing plays a significant role in speeding up the prototyping process. By using 3D printing technology engineers can create and test revised designs through fast printing cycles which take hours or days for each round. The rapid iteration method speeds up experimental testing even as it decreases the time needed before market entry. 3D printing serves NASA and SpaceX for component tests and refinement procedures so they can evaluate rocket parts in high-stakes space missions. The industry advances rapidly with precision because designers can convert their conceptual work directly into physical objects.

How Is 3D Printing Fueling Innovation Beyond Earth?

Aerospace 3D printing displays its most thrilling application when used for space exploration purposes. NASA, together with SpaceX, prints rocket components that need fewer segments while minimizing weight with less complicated design requirements. Team members conduct studies about printing operations inside space facilities to produce mission-specific equipment during missions. The innovation presents the potential to modify the way people travel through space for extended periods. The aerospace industry selects innovative material research and oversized creative designs, which motivate the healthcare sector and automobile industry to pursue similar developments.

Conclusion

3D printing represents more than an industry trend because it has changed aerospace engineering into a groundbreaking discipline. Thanks to its weight-reducing ability, design enhancement capability, and production speed-up features, the industry achieves unprecedented achievements. As testing and materials continue to improve, even more possibilities will unfold. Consider 3D engineering for the best 3D printing solution and experience how precision can power progress.