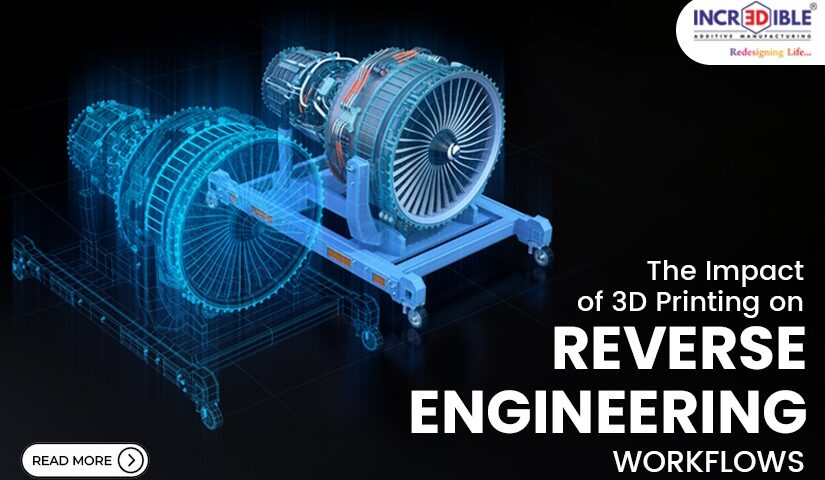

THE IMPACT OF 3D PRINTING ON REVERSE ENGINEERING WORKFLOWS

Reverse Engineering includes separating a real item to grasp its plan, usefulness, and development. It is pivotal in different industries, such as manufacturing, automotive, aviation, and healthcare, for item development, quality control, and innovation. By dismantling items, engineers can make progressed versions, duplicate ceased parts, and guarantee compatibility with existing frameworks.

The presentation of 3D printing in reverse engineering has altogether upgraded these processes. 3D printing empowers the creation of exact digital models through filtering and then produces exact physical replicas. This capability streamlines prototyping, testing, and refining plans, making reverse engineering more productive and cost-effective.

3D Incredible excels in utilizing 3D printing technologies for reverse engineering applications. With their ability, they help clients transform scanned data into high-quality 3D printed models, encouraging fast development and emphasis. 3D Incredible innovative solutions empower industries to use the total potential of 3D printing in reverse engineering, driving advancements and guaranteeing prevalent results.

Enhancements in Reverse Engineering Workflows with 3D Printing

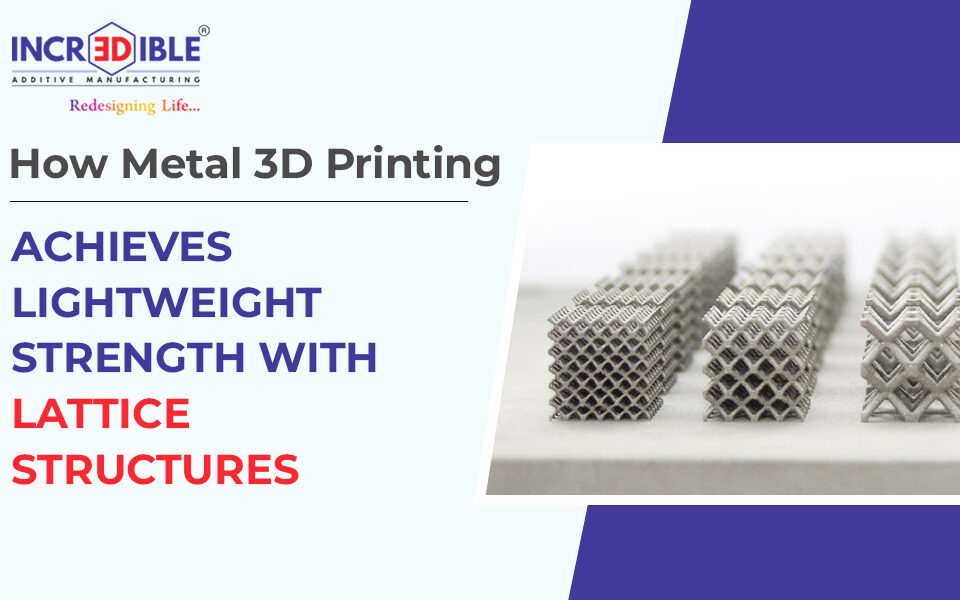

3D printing revolutionizes reverse engineering by simplifying the digitization of physical objects and creating exact replicas. Scanned data is transformed into digital models, empowering fast prototyping and testing. This streamlining saves noteworthy time and costs compared to conventional strategies. 3D printing enhances accuracy, guaranteeing each detail is faithfully reproduced, which is crucial for businesses like aviation and healthcare. Moreover, it provides engineers with enhanced design capabilities, facilitating cycle and advancement. For illustration, in car reverse engineering, 3D printing empowers fast prototyping of parts for testing, accelerating the development process. Essentially, in therapeutic device manufacturing, 3D printing produces precise models for surgical planning, improving patient results. Generally, 3D printing optimizes different tasks within reverse engineering workflows, driving efficiency and innovation.

Day-to-day applications of reverse engineering.

Product Improvement: Reverse engineering helps in analyzing existing products to enhance features, performance, and usability.

Interoperability: By understanding the plan of different systems, reverse engineering ensures compatibility and smooth integration between various technologies.

Legacy System Integration: It helps in the coordination of old systems with modern innovations, amplifying their usability and functionality.

Security Analysis: Reverse engineering recognizes vulnerabilities in programs and hardware, empowering better security measures and protection against cyber dangers.

Intellectual Property Protection: It helps in confirming that items do not infringe on existing patents, shielding intellectual property rights.

Reverse engineering, subsequently, plays a significant part in technological advancement and everyday application

Conclusion

The integration of 3D printing has revolutionized switch-building workflows, offering exceptional efficiency, precision, and development. Through digitization of physical objects and the generation of accurate replicas, 3D printing streamlines forms, reduces costs, and accelerates development timelines. The benefits extend over businesses, from aviation to healthcare, where 3D printing upgrades prototyping, testing, and customization.

3D Incredible Engg stands at the forefront of this change, offering 3D printing solutions to optimize reverse engineering processes.

Their mastery and innovative approach enable clients to overcome challenges and accomplish superior results. By collaborating with 3D Incredible Engineering, companies can unlock the total potential of 3D printing, driving innovation and remaining ahead in their respective industries.