Powders for Metal 3d Printing

Metal additive processes such as metal powder bed fusion and directed energy deposition are potentially capable of producing high-quality, functional and load bearing parts from a variety of metallic powder materials.

Today, metals are the fastest-growing segment of 3D printing. The growth of additive manufacturing is tied to business opportunities and, directly, the materials available and their cost. Low-cost metal powders are the key enablers for 3D printing, to realize its potential and transform industrial production.

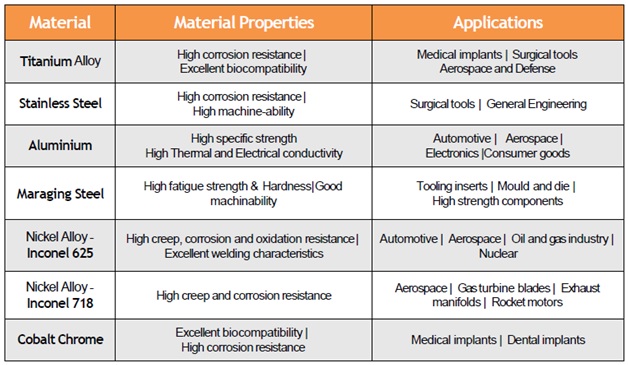

Available metallic powders for additive manufacturing are mostly those being used in a range of applications (medical, aerospace, jewelry, automotive, etc):

- Maraging steels

- Stainless steels,

- Aluminum

- Cobalt-chromium

- titanium

- Inconel

Metal powders can vary widely in size, but also in shape (spherical to irregular). As a consequence, processing characteristics in AM metal systems vary, as well. To ensure consistency and repeatability of the quality of metal powders and AM processes, the machine manufacturers are working closely with powder suppliers.

Metal powder for additive manufacturing (3D printing, rapid prototyping) are characterized by a spherical morphology and high packing density, which confer good flow properties. For powder bed processes these are essential when applying fresh powder layers to the bed to ensure uniform and consistent part build.

Metal powders used in additive manufacturing should have:

- spherical shape to ensure good flow/coating ability and a high packing density,

- particle size usually below 50 μm or 150 μm depending on machine type and surface finish or productivity required,

- particle size distribution tailored to the application and properties,

- controlled chemical composition and gas content.

The particle size distribution of metallic powder particles impacts the density of AM parts. Although it’s possible to attain high densities with different powder types, the parameters of the process must be adjusted accordingly. Ultimately, the productivity varies. Moreover, the particle size distribution does not only affect the density but also the mechanical properties and surface quality of the parts.

In search of a low porosity, fine microstructure and uniform properties!

Repeatedly obtaining additively manufactured materials with 100% of the reference density is doubtlessly challenging. Metal additive manufacturing techniques can yield densities in excess of 99%. Some materials are reported with a full density while some others present a spread of densities.

Density is influenced by the development of pores or entrapment of unmelted powders during the layering. Occasionally, hot isostatic pressing is used to increase as-fabricated densities.