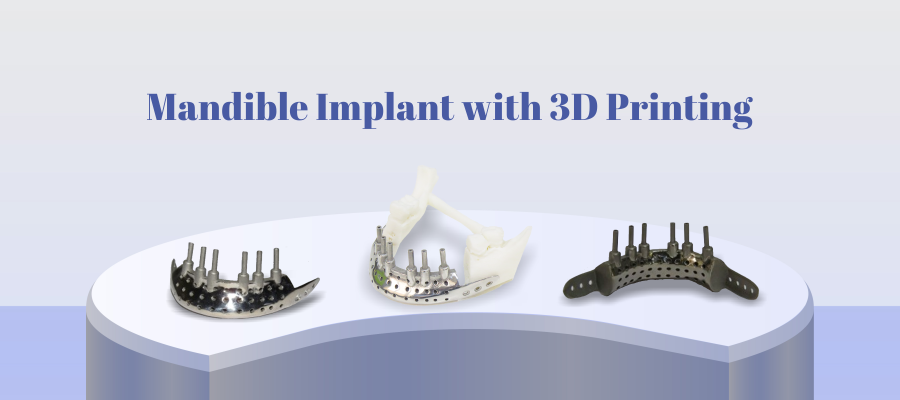

With evolving technology, 3D printing is becoming a great asset to the medical industry (Mandible (jaw) Implants with 3D Printing), especially for facial injuries which are very complex and treating them is a big challenge for any surgeon. The mandible is one of the facial parts which need reconstruction prominently to bring functionality back. It can happen after an accident, cancer or a malformation. They are complex in shape and needs accuracy and Additive manufacturing technology is really useful for such surgeries. With 3D printing, one can create parts of the new jaw of the patient, adapted to his anatomy and movements.

What is a 3D Printed Mandible (Jaw) Implants?

The jaw is a pair of bones that form the framework of the mouth, usually containing teeth and including a movable lower jaw (mandible) and fixed upper jaw (maxilla). Mandible (Jaw) or Mandibular implants are the implants that replace the present bone defect providing exact anatomy and aesthetics along with functions. Also, such implants will help to fix autologous bone graft at the defect.

Why Prefer 3D Printed Mandible Implants Over Traditional Implants?

Mandibular reconstruction is a complex process as it requires different operations. With the traditional procedure, treatment of jaw tumours required the removal of a section of the jaw through an incision on the side of the face that could be up to four inches long. Then a piece of bone taken from the leg (fibula) or hip would be grafted into the space. It is a critical process with a low possibility of getting the perfect result as it requires utmost precision.

With 3D printing technology, the process gets relatively easier with the advanced visualization offered by 3D modelling software. It is now possible to get a CT scan of the patient and to convert it into 3D model that one can be simulated for surgical planning. It helps in 3D visualization of jaw defects and understanding different possible simulations. Once the design is finalized, the implant can me simply 3D printed with utmost precision and quality. These implants even provide better aesthetics and faster recovery time.

Benefits of 3D Printed Mandible Implants

3D printed mandible implants are beneficial for surgeons as well as patients in numerous ways-

- Good Aesthetics : This is one of the major benefits of 3D printed mandible implant. After the mandibular reconstruction, often chances are high that patients are left with a disfigured face along with visual scars which can leave a lasting impact on patients mental state. 3D printed mandible implants are capable of providing a complete original facial structure which makes patient more confident and lead a regular life.

- Perfect Fit : With 3D printing technology, it is possible to design customized mandible implants according to the anatomy of the patient. The perfect fitting of implants helps the patients in retaining their natural oral movements (functional rehabilitation) during eating and chewing of food, which is considered a huge success in jaw reconstruction surgery.

- Fast Recovery of Patient : Another potential benefit of computer-assisted surgery is the improvement of accuracy of mandibular reconstruction. The patient-specific 3D printing implant eliminates the process of bone grafting and the associated months of recovery. It saves the patient from possible inflammation and provides the patient with much faster recover.

- Biocompatible Material : Several studies indicate that not all patients can tolerate metallic (especially those containing Nickel, Cobalt, and Chromium) based implants expressing immunological allergy indications due to metallic ions. The mandible implants are made from titanium (Ti6Al4V Eli) which is considered the most biocompatible metal due to its resistance to corrosion from bodily fluids, bio-inertness, and high fatigue limit.

- Less Surgery Time : The traditional freehand surgery is a serious undertaking which often requires on OT table bending/molding of standard size implants to adapt it as per patient anatomy. This results in longer surgery time due to which patient spends more days in intensive care or in the hospital. With 3D printed implants, where the surgery takes just a few hours and recover takes lesser days. .

- Precise resection : 3D printed implants make reconstructive surgery less painful for patients. Suppose, if a patient has a tumor at his lower jaw and reconstructive surgery is required, doctors will have to remove the tumor from his lower jaw, but it won’t be possible without removing the left side of the jaw which means removing a lot of teeth. But with 3D visualization, doctors can clearly see the issue and try to solve it. They can make 3D printed surgical guides and titanium plates for precise jaw reconstruction. The jaw can be then reconstructed using a part of the patient’s fibula. . Usually, when doing jaw reconstruction, different operations are required but with 3D printing technology, it can be done in single time causing less damage to the patient.

Conclusion:

3D printed mandible implants are making life better for a whole lot of patients suffering from tumors or jaw injuries. 3D printing technology continues to take the medical field to new heights with its innovative advancements. While this is a boon for scientists, surgeons, and hospitals—patients are often the ones emerging as the real winners.