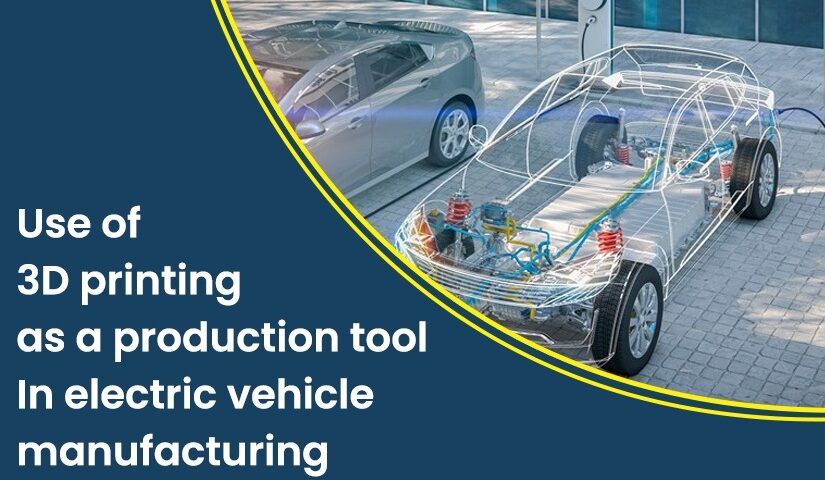

3D printing or additive manufacturing helps create a physical object from a CAD file. Since this is a material addition process, very little or no material gets wasted during produced production. Layer after layer is added to the object until it is printed in its whole.

Since 3D printing is inherently a promising manufacturing technique, it is becoming a common production procedure for electric car manufacturers. The several advantages of 3d printing allow EVs to expand, lower the cost of items for common consumers, and contribute to a future where the globe is more environmentally friendly and sustainable. It also provides a more sustainable and safe manufacturing option to OEMs.

Incredible in Pune, a pioneer in 3d printing in India, aid electric vehicle manufacturers by offering different 3d printed parts and components used by them. Here, let us find out how 3d printing is a production tool in electric manufacturing.

3D printing has several advantages, and electric vehicle manufacturers are actively leveraging these advanced services to streamline various operations with higher agility. Scroll below to know the critical aspects where 3d printing plays a significant role.

Manufactures car shell

The production of automobile shells is one of the crucial industries where this technology is employed extensively for electric vehicles. It facilitates a faster and less expensive prototype process.

With conventional manufacturing, prototyping and testing for a fully functional car are expensive affairs. The process can be sped up, and the number of iterations can be decreased with 3-D printing. Companies are able to create a huge number of test shells quickly and efficiently with the use of 3d printers.

Produces mass customization

Mass customization of auto parts is another application for 3D printing. Without the need for costly tooling, it makes it easier to generate distinctive and one-of-a-kind components.

It allows manufacturers to better serve the needs of specific clients, which is a big advantage.

Any pattern or shape can be made, and it can be customised to the needs of the buyer. The market for customised vehicles is enormous, and 3D printing is essential if you want to meet clients’ requests on a large scale.

Produces parts and components

Electric cars have a lot of 3D-printed parts. The most popular ones include AC ducts, gears, fasteners, and brackets. 3D printing improves the strength and durability of these components while also helping to reduce their weight. The best thing about 3D-printed components is that they are affordable and practical for batch production and provide a viable solution for the mass production of small and critical parts.

Produces heat-resistant battery fixtures

Keeping the battery cool is one of the biggest problems with electric cars. The battery’s life may be shortened and damaged by the high-temperature environment. 3d printing can create heat-resistant battery fixtures that aid in heat dissipation and battery cooling.

Uses a wide range of material

A broad variety of unique materials for electric vehicles are now available. Thanks to 3d printing technology! With 3D printing, OEMs can utilise a variety of additive printing materials in a single print job, each of which has advantages and features of its own.

As a result, it offers businesses the freedom to select the ideal material for the job and aids in lowering production expenses and time.

Produces molds for casting parts

Molds are also made via 3D printing and then utilised to cast items. It aids in minimising the time and expense involved with conventional procedures.

Companies are able to create molds with specific shapes using three-dimensional printing. In addition, it enables the low-cost, mass production of moulds. It makes it a practical choice for producers of electric vehicles.

Using additive manufacturing, it becomes simpler to create flawless, high-quality molds. As a result, it aids in enhancing the quality of the finished product and satisfies the exacting standards of electric vehicles.

Digitizes inventory

With this technology, businesses no longer need to mass-produce parts and store them for later use. Inventory management is made simpler as a result of OEMs’ ability to produce parts as needed. As a result, it aids in cutting down on manufacturing time and expense.

Designers are able to create CAD files and make the team’s digital inventory available. By lowering the number of components that need to be stocked, it enhances the supply chain.

For businesses, the logistics supply chain represents a rising overhead, which 3D printing can assist to alleviate. By assisting in the on-demand production of parts, additive manufacturing reduces the logistical burden.

Enhances braking system

The manufacture of brake components for electric vehicles also uses this technology. The performance and lifespan of the brake system are both enhanced by the use of additive manufacturing.

Brake parts are made of materials like titanium, aluminium, and stainless steel. They are sturdy and light, which aids the electric vehicle’s braking performance. It enables producers to make brake parts in greater quantities and at a reduced cost.

Enhances futuristic aesthetics

Body panels and other exterior components for electric vehicles are created via 3D printing. It enhances the car’s appearance and gives it a futuristic look. Additionally, it enables mass production of body panels at a significantly lower price.

Utilizing three-dimensional printing, businesses might examine fresh design options for electric autos. Additionally, it aids in the development of original exterior designs that might distinguish your goods from the competitors. It improves the company’s reputation as a brand and aids in attracting customers.

Wrap up

Electric vehicles are the latest trends in the automobile industry and the future of transportation. All automakers will eventually switch to full-scale EV production. This process is accelerated by additive technologies since they are less expensive, safer, and quicker. The development and success of the electric car sector are greatly aided by 3D printing.

Incredible AM Pvt Ltd with a state-of-the-art infrastructure makes use of the latest high-quality printers, licensed software, and other machines to develop 3d printed objects. Our skilled staff continually attempts to develop goods with better characteristics. We make use of all of the 3d printing sub-technologies, including SLM, DMLS, DMD, and a wide range of 3d printing materials at our manufacturing facility. So, we are the one-stop 3d printing solution for all manufacturers including electric vehicle manufacturers. For any queries related to 3d printing, contact us.