The rapid advancement in 3D printing has transformed the medical field. Among the numerous applications of this modern technology, 3D-printed implants stand out as a beacon of innovation. From customised prosthetics to complex orthopaedic implants, 3D-printed implant technology is rapidly evolving. In this blog, we’ll learn about 3D printed implant technology which is rapidly evolving and its current applications in the healthcare sector.

Personalization and Precision

One of the most significant benefits of 3D-printed implants is their ability to offer tailored solutions to the specific needs of individual patients. It creates patient-specific implants based on the patient’s anatomy, ensuring a precise fit and reducing the risk of complications.

Complex Geometries for Enhanced Functionality

Implants with intricate and complex geometries are challenging to produce using traditional manufacturing processes. 3D printing excels in this regard. Hip and knee replacements, for example, can be designed with complex structures that mimic the natural anatomy of bones and joints. It improves implant functionality and promotes better integration with the patient’s existing tissues.

Bioabsorbable Implants for Temporary Support

3D printing allows the creation of bioabsorbable implants that provide temporary support before gradually dissolving the body. It is useful when the implant aids in the healing process in the early stages. The patient’s natural tissues take over as the implant dissolves, reducing the need for a second surgery to remove the implant.

Advancements in Materials

The materials available for 3D printing are constantly expanding, allowing for the creation of implants with a wide range of properties. Biocompatible and bioresorbable materials, and composite materials that closely mimic the mechanical properties of natural tissues, are examples of innovations. These developments help to create implants that are functional, safe and compatible with the human body.

Accelerated Prototyping and Iterative Design

3D printing helps in rapid prototyping, allowing researchers and engineers to quickly iterate designs. This expedited design process allows for more efficient exploration of novel implant concepts and the incorporation of feedback from healthcare professionals. As a result, the development cycle is faster and more agile, benefiting patients with improved and innovative implant solutions.

Dental Implants and Maxillofacial Reconstruction

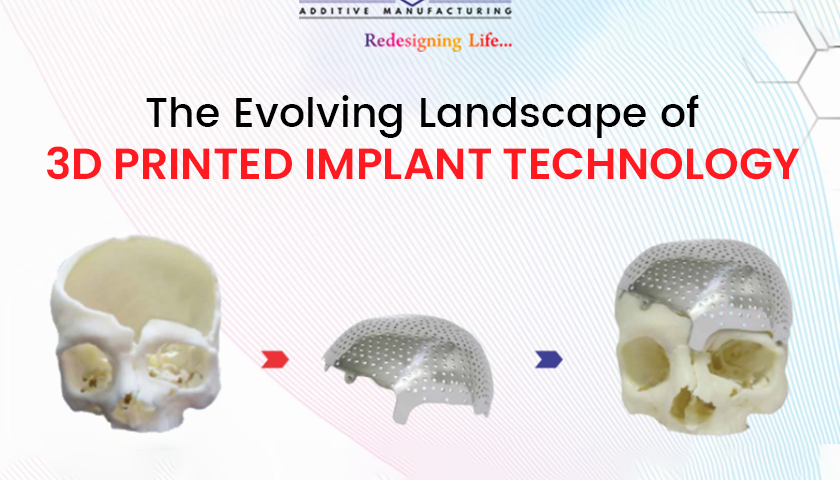

For the production of dental implants and prosthetics, dentistry has embraced 3D printing. The ability to create customised crowns, bridges, and even entire dental implants 3D printing has transformed the landscape of restorative dentistry. Furthermore, 3D-printed implants are used in maxillofacial reconstruction to restore facial structures with remarkable precision.

Future Directions and Challenges

Despite the remarkable progress, there are still challenges, such as the need for standardization, regulatory considerations, and production scaling for widespread adoption. Nonetheless, ongoing research and collaborations among medical professionals, engineers, and regulatory bodies pave the way to overcome these challenges. Further breakthroughs in materials, manufacturing techniques, and the integration of 3D printing with other advanced technologies, such as artificial intelligence, await.

Conclusion

The 3D-printed implant reshapes how healthcare professionals approach patient care and medical interventions. 3D-printed implants are a testament to the transformative power of innovation in healthcare in this exciting journey of technological advancement.

Incredible AM Pvt Ltd. in Pune, the pioneer in 3d printing in India, offers several 3d printed implants that perfectly fit the patient’s anatomy. We use the best bio-compatible materials, such as titanium alloy (Ti6Al4V ELI Grade 23), PEEK and PMMA, to create these implants. Our world-class manufacturing unit supports us in achieving the best result.