Rethink with 3D Metal Printing

Metal fabrication is no more limited to cutting and forming components or parts. Thanks, 3d printing has opened new ways to fabricate metal parts. The idea of building up raw material into the desired shape is not just a concept but a reality. Additive manufacturing techniques are not replacing the traditional manufacturing methods, but the emergence of advanced and efficient 3d printers is compelling us to rethink how we can bring changes in metal fabrication.

3D metal printing has several advantages over conventional manufacturing, so it is wise to expand and grow your business using the latest technique. 3D Incredible AM Pvt Ltd of Pune is the pioneer of the latest technique in India. With the experience of over 45 years, we are well aware of the vast potentiality of this incredible technique and use it to develop parts, right from designing to the finished products.

Let’s be informed about the latest manufacturing technology so that you can make the right decisions.

How does 3D metal printing benefit us?

Freedom in creating complex geometric shapes

3D metal printing allows you to create complex geometric shapes. Any kind of overhangs or intricate geometries is created with ease, in less time, and cost-effectively. The additive process where parts are produced by layering eliminates the need for complicated machine setup and excessive material removal.

No tooling and fixtures required

Unlike traditional manufacturing, 3d printed parts do not require tooling and fixtures. Fabricators can create parts with minimal overhead. This reduces part costs for low-volume production. Moreover, in traditional methods, tooling costs have been prohibitive in creating innovative parts and for low-production parts, but the lack of tooling allows fabricators to create new components.

Automation

In conventional manufacturing, skilled operators are required at every step. It leads to extra costs and time. While 3d printing produces parts automatically from design files. It requires minimal human intervention, making production fast and cost-effective.

Customization

The production of customized parts is one of the most important aspects of metal 3d printing. The technology aids in making alterations or modifications in the existing products or in creating new products as per the requirements of the customers. It thus helps to customize your prototypes without any added cost.

Eco-friendly

The conventional manufacturing processes generate a large amount of waste materials and consume a lot of energy. In contrast, additive manufacturing utilizes less energy, and the waste is reduced to a bare minimum. Hence, it proves to be cheap and environmentally friendly.

Metals that are used in 3d printing

Additive manufacturing uses a wide range of metals in its powdered form for metal fabrication. Low-cost metal powders used in 3d printing are helping in transforming industrial production. Important metals used in the process are:

- Maraging steels

- Stainless steels

- Aluminum

- Cobalt-chromium

- Titanium

- Inconel

Metal powders vary in shape and size. These are characterized by a spherical morphology and packing density that confers to good flow properties. In addition, it also affects the mechanical properties and surface quality of the parts formed.

Features of metal 3d printing

Rapid Prototyping: Metal 3d printing begins with the creation of a CAD model of the part that needs to be produced. A prototype based on a CAD model is produced using the layering method for testing. The prototypes reduce the time, cost, and effort required for product development.

Weight Reduction: Metal 3d printing produces light-weight parts through innovative lattice structures. The method helps to sustain heavy loads at the lowest part to weight ratio.

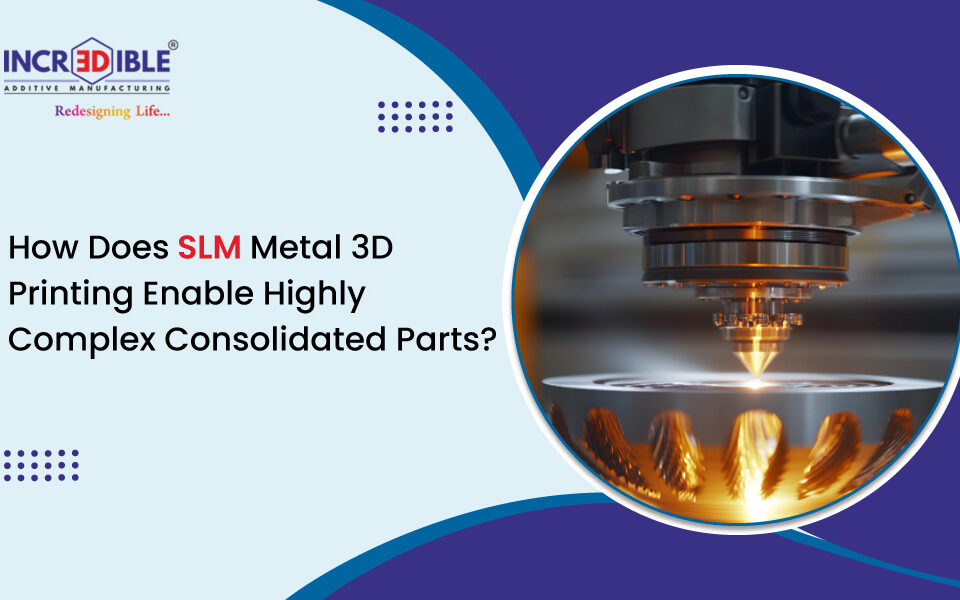

Parts consolidation: Additive manufacturing helps in merging the parts in the CAD model instead of joining parts through welding, bolting, riveting, etc.

Reverse engineering: Reverse engineering helps in reviving obsolete machines by scanning damaged parts. The defective parts are replaced by 3d printed parts without contacting the original manufacturer.

Virtual inventory: The advent of additive manufacturing has made the concept of digitalized inventory a reality, which can be used whenever and wherever required.

3D Incredible AM Pvt Ltd provides you with the solutions for your metal 3d printing requirements

The well-equipped plant of 3D Incredible in Pune makes use of the latest high-quality printers, licensed software, and other machines to develop 3d printed metal parts. Our well-adept workforce consistently works to produce products of enhanced qualities. At our manufacturing plant, we make use of all the sub-technologies of metal 3d printing, such as SLM, DMLS, DMD, etc., available in the market. We use a wide range of metals to produce parts that are required in diverse industries such as aerospace, defense, automobile, energy, healthcare, tooling, etc.

Conclusion

Thus, if you’re now considering making the best use of metal 3d printing for your business, our world-recognized 3D Incredible is always at your service. Do contact us, for your metal 3d printing requirements.