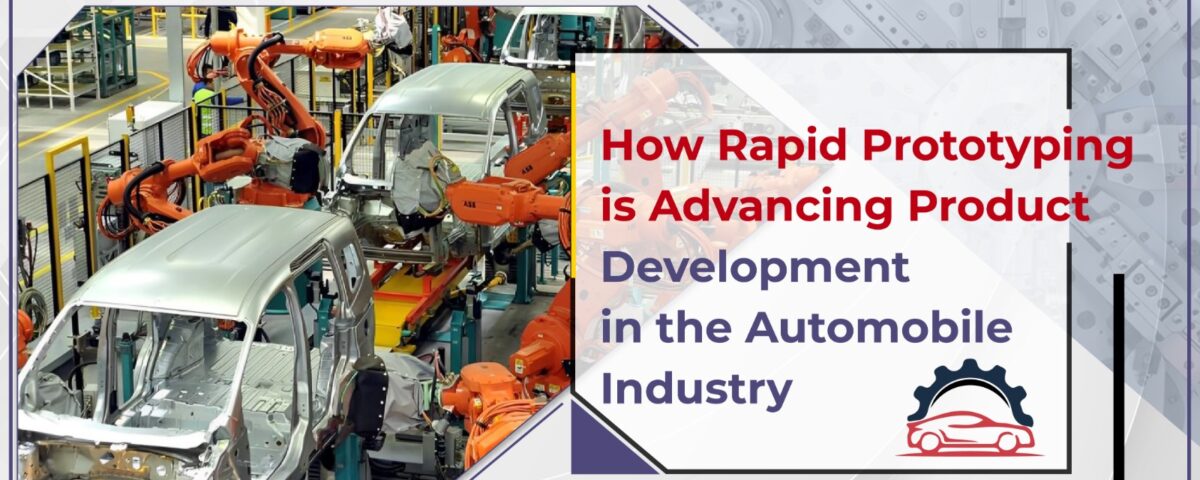

How Rapid Prototyping is Advancing Product Development in the Automobile Industry

Customers are demanding change in car manufacturing and joining a rapid transformation due to ongoing breakthroughs in safety, environmental, and technical issues. In this highly competitive market, producers must design value-functional items while meeting the constraints of quick production times and cheap production costs. Rapid prototyping can be named the revolution in the technological process as it enables the creation, prototyping, and examination of automotive parts with minimum risks. With technological advancements such as 3D printing and computer numerical control machining services, the industry has adopted higher standards in the development of products by meeting higher accuracy and productivity standards.

The involvement of rapid prototyping in automotive stylish design

Automobile Rapid Prototyping is the development of representations of improved or new parts and subsystems through additive manufacturing technologies. Unlike many other approaches, it accumulates layers of material to make something such as a prototype, which requires little tooling. The automotive industry uses rapid prototyping techniques to test car part designs for effectiveness, sturdiness, and style before going to full production. It eliminates the chances of many products being returned and increases product quality and safety.

Why is Rapid Prototyping a Key to Success for Automobile Manufacturers?

- Faster Design Iterations

Rapid prototyping cuts down immensely on the time required to switch from a mere idea to an experimental model. As an example, using 3D printing, it is possible to model something that has never been designed before without having to go through molds or much preparation. This enables automotive manufacturers to test designs from different angles, ensuring optimal results in record time.

- Enhanced Testing and Validation

By creating functional prototypes, automakers can conduct rigorous testing to ensure components meet safety and performance standards. For instance, prototypes can undergo stress tests to evaluate strength or fit within the overall vehicle structure. This type of validation assists engineers in determining design errors before production, reducing the costs that are associated with corrections at this stage.

- Cost-Effective Solutions

Conventional production systems are very costly in terms of tooling and setting, particularly when the required production quantity is low. Rapid prototyping reduces expenses by being cheaper than traditional methods. Its use of shared digital models for multiple projects also enhances cost-effectiveness, making it attractive to budget-conscious automotive manufacturers. Rapid prototyping eliminates certain expenses, as it is significantly cheaper than traditional methods. Additionally, using the same digital models for multiple projects increases economic benefits compared to costly shop tools, making it an appealing option for cost-sensitive automotive manufacturing companies.

Technologies of Rapid Prototyping

3D printing plays a crucial role in defining rapid prototyping, enabling the creation of highly accurate models using various materials such as plastics, metals, and composites. This technology is most suitable for carrying small and detailed designs and lighter forms of structural designs, which are rapidly becoming common in current car models. When a manufacturer requires two or more tools or requires precise samples, rapid tooling, such as injection molding, can sufficiently answer the requirements.

Applications of Rapid Prototyping in the Automotive Industry

- Design Verification

Techniques like automobile rapid prototyping can test new ideas effectively by eliminating guesswork and providing tangible models. This decreases the chances of designing an imperfect product and guarantees that the end product is functional and safe.

- Market Research and Feedback

Prototypes are essential for gathering consumer feedback and conducting market research. Automakers can present prototype models at auto shows or focus groups to gauge public interest and make improvements based on insights.

- Enhanced Accuracy and Safety

Automotive production requires a high degree of accuracy because any deviation might cause catastrophe on the roads. Rapid prototyping means accurate dimensioning and material specification, minimizing the chance of defects being transferred to mass production.

Conclusion

Many product development processes in the automotive industry have been greatly enhanced by the integration of rapid prototyping technology that has made design cycles faster, manufacturing cheaper, and product testing improved. It enables the players in the automotive sector to proceed to innovation securely and to launch new vehicles that need to be safer, smarter, and more sustainable. Rapid prototyping from 3D engineering is therefore expected to remain a fundamental pillar of the advancement of automotive technology as the industry moves towards the possibilities of a seemingly limitless world.