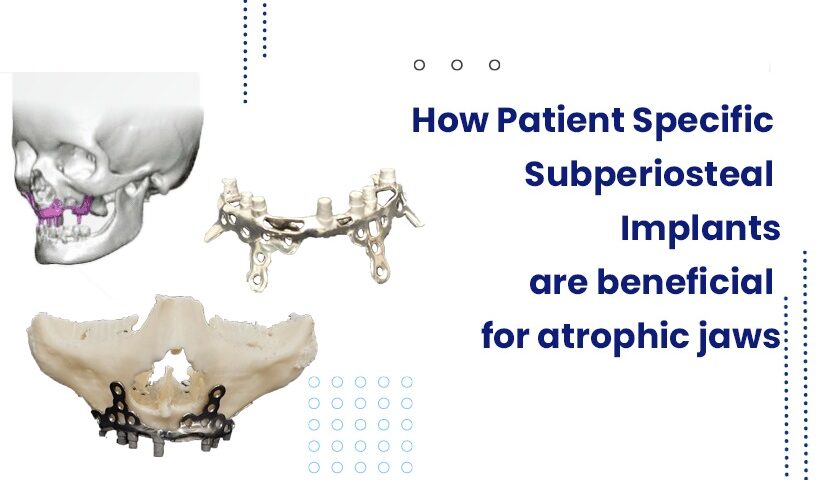

Patient-specific subperiosteal dental implants are prepared from a metal framework and inserted into the bone. The placement of this framework is done under the gum tissue but above the jawbone. Patients with atrophic jaws or patients suffering from bone loss in their jaw need to go for subperiosteal dental implants.

The 3d printed implants have several advantages for patients with atrophic jaws. The subperiosteal dental implants are set on top of the bone, and therefore, it does not depend on the shape or amount of bone present in the mouth. The technique eliminates the steps involved in conventional methods, such as bone grafting, and helps in a speedy healing process and working of implanted teeth.

3D Incredible Pvt Ltd, located in Pune, offers patient-specific implants and services to assist a surgeon and patients in the best possible way. Here, we use 3d printing, the latest manufacturing technology for developing complex and intricate shapes without tooling. Using the ‘Near Net Shape’ manufacturing process, we built parts very close to the required dimensions with an accuracy of 0.2 mm.

Challenges to the rehabilitation of atrophic jaws using conventional methods

Rehabilitation of atrophic jaws using conventional methods poses several challenges. Autogenous bone grafting and guided bone regeneration are common reconstructive procedures, but these have limitations. While autogenous bone grafting requires a second surgical site, implying additional morbidity, and immediate loading is avoided, guided bone regeneration is often limited in gain and is also associated with possible complications in total atrophic jaws. These techniques require months for graft maturation.

Other techniques used in the rehabilitation of atrophic jaws are tilted implants and zygomatic implants. Though these techniques provide stable long-term results they are also not totally reliable as atrophic jaws are associated with anatomical changes. Due to this, there is an increased risk of injury to noble structures and increases the need for specific surgical skills during surgery. Zygomatic implant procedures require local or general anaesthesia and a favourable zygoma bone are essential to support the implant.

Patient-specific subperiosteal implants are fast emerging as a better solution for the rehabilitation of atrophic jaws, suitable for both maxillary atrophy and mandibular bone deficiencies. These implants are made using additive manufacturing techniques which begin by creating a computer-aided design (CAD) file and then obtaining 3d printed implants using biocompatible material such as titanium alloy. The implant made by the layering of material has several advantages.

Advantages of using patient-specific subperiosteal implants for atrophic jaws

- These implants give good aesthetics as they are created according to facial symmetry. Patients with atrophic jaws are greatly benefitted from this implant.

- Patient-specific implants are made based on the anatomy of the individual patient hence they provide a perfect fit for the patient.

- Because these implants provide perfect fit it results in fast recovery of the patients.

- Typically these implants are made using titanium alloy hence they are lightweight and have high strength.

- The patient-specific subperiosteal implants have high corrosion resistivity and low thermal conductivity.

- The custom-fit implants created by 3d technology help surgeons in performing surgery with high accuracy and precision.

- These implants cause no damage to the patient and help them in fast recovery after the surgery.

Conclusion

Additive manufacturing technology using 3d printing is revolutionizing facial reconstructive surgery. The 3d printed subperiosteal implants help both surgeons and patients. 3D Incredible is a pioneer in 3d printing technology in India and is helping various sectors, including medical and dental, with its incredible products and services. Connect with us to get 3d printed patient-specific subperiosteal implants for atrophic jaws with great features.