In the past few decades, demand for patient-specific implants has increased significantly worldwide due to the use of implants in total joint reconstruction, total knee reconstruction, total hip reconstruction, spine fixation, etc. In addition, these arthroplasties are becoming common in younger people. Surgical implant devices in orthopedic surgery are not new but the modern patient-specific orthopedic implants have emerged as a promising treatment due to many factors, perfectly matching an individual’s anatomy being the best reason. Customized 3d printed jigs and cutting guides have improved the accuracy in various orthopedic reconstruction procedures.

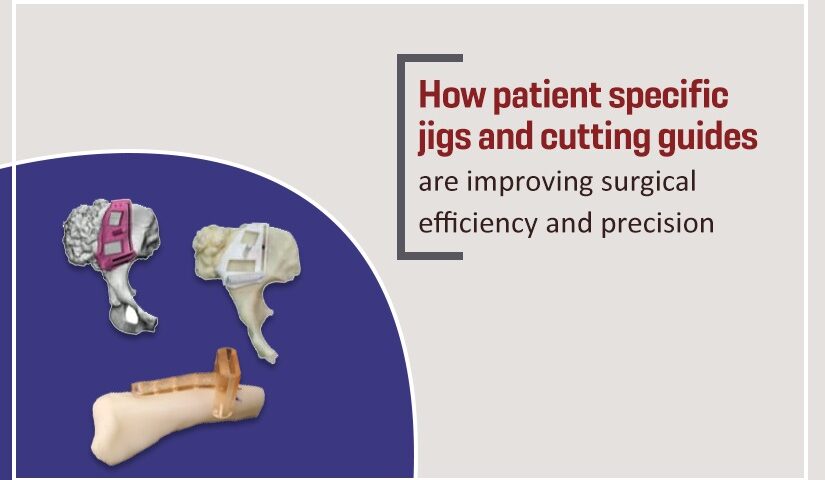

Incredible AM Pvt Ltd located in Pune with its brand LimbSal Ortho is facilitating the reconstruction of large joints such as hip and knee and also shoulder, wrist, elbow, ankle, etc. with its high-quality additive manufacturing technique. It provides customized jigs and cutting guides that are improving surgical efficiency and precision. Let’s have a look at how these 3d printed jigs and guides work and benefit in orthopedic reconstruction surgeries.

Benefits of using patient-specific jigs and cutting guides

Customized jigs are used to produce a preoperative plan for the surgeons during surgery. Since these jigs are designed on the basis of preoperative CT scans or MRIs, they are customized and thus fit the surface of the bone only in one configuration. This helps the surgeon in placing the jig at the correct location. The customized jigs also help the surgical cutting tools reach the site of the defect. This enables the surgeons to reproduce an ideal preoperative plan.

Customized cutting guides or surgical guides help in osteotomy drills at the right position, angle and depth. They facilitate placing the implants at their designated positions and also guide in the amount of reduction of bone and bone harvesting. In addition, they eliminate the errors confronted during the manual placing of the implants. Surgical guides allow minimal intervention and hence they minimize post-surgical problems. These psychologically benefit both the patient and the doctor.

At 3D Incredible Pune, we use Magnetic Resonance Imaging (MRI) and computed tomography (CT) scan and US FDA and CE approved licensed Materialize Mimics software to get anatomical models. These models maintain a 1:1 ratio with the anatomy and hence show detailed defects. These are used to design jigs and cutting guides and also help in pre-surgical planning.

Why are customized jigs and cutting guides of 3D Incredible the best?

3D Incredible of Pune is the first company in India that works in Medical 3d printing in a certified world-class facility. Our customized jigs and cutting tools help the surgeon to give an accurate cut and complete the surgery in one go. These patient-specific surgical tools are made of biocompatible materials such as PLA, ABS, Nylon, Ti6AI4V – ELI, etc.

They help in the precise resection of bone tissues to perfection. They are customized as per surgeon requirements, are easy to use, and conserve bone tissue.

Our customized surgical tools help to reduce OT time as there is no adaptation of standard implants at the time of surgery.

Our state-of-the-art infrastructure at Pune is well-equipped with the latest and the most advanced technology to provide a specific and accurate solution for additive manufacturing technology. The unit is designed and built as per FDA requirements. Here, the jigs and cutting tools are manufactured under ISO 13485 guidelines and tested to give the best result.

Since we deal in invasive medical products, we take extra care in maintaining quality and regulatory requirements. Our medical device manufacturing performs in 10,000 cleanrooms. In addition, we conduct validation/calibration of equipment on a regular basis through NABL accredited laboratory to ensure the quality of the product.

Conclusion

The modern method of medical implants has made the task of doctors much easier and assured patients’ satisfaction. The patient-specific jigs and cutting guides help in attaining precision and accuracy. These have eliminated many problems that are faced by surgeons in manual implantations. 3D Incredible of Pune collaborates with the world’s most skilled and experienced biomedical engineers, mechanical engineers, doctors, etc. to manufacture patient-specific jigs and cutting guides to attain precision and accuracy during surgery. So, if you require customized jigs, cutting guides, and implants we are the best manufacturer who offers you patient-specific products at a cost-effective rate.