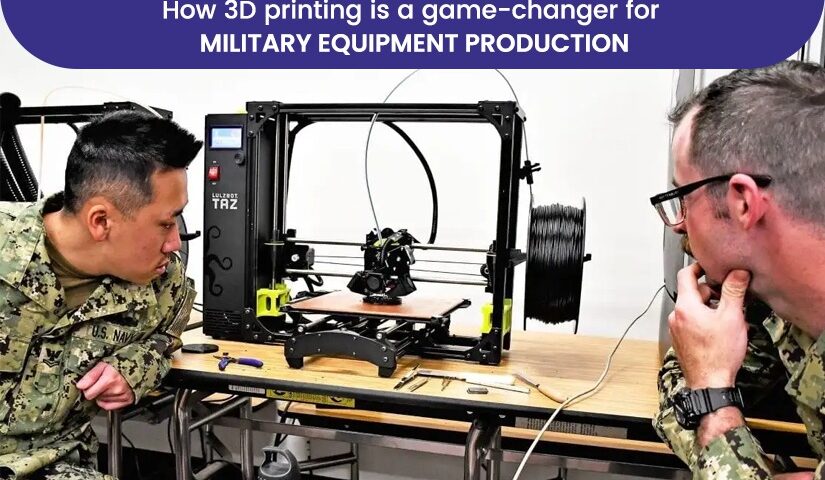

Additive manufacturing has the potential to open up a slew of new opportunities for the defence industry, including lower production costs for tools and components, increased design flexibility, and localised manufacturing. At the same time, additive manufacturing can significantly improve military system maintenance by producing spare or obsolete parts. The defence industry is a major contributor to the ongoing development of additive manufacturing technologies and materials.

Incredible AM Pvt Ltd of Pune is a pioneer in 3d printing in India offering incredible 3d printed products and services for application in different industries. It caters to serve defence and manufactures various tools, machinery and equipment used in the military. Like other sectors, 3d printing is also revolutionising the defence and military sectors.

In this blog, let us see how 3d printing is a game-changer in producing military equipment.

Advantages of using 3d printed military equipment

- Fast product development

Because no tooling is required in additive manufacturing, it significantly speeds up the design process. Traditional manufacturing methods take months to produce the tools required for creating end parts and prototypes. As a result, the defence industry can use the technology to avoid costly and time-consuming tooling, reducing the time required for product development.

- Freedom in designing

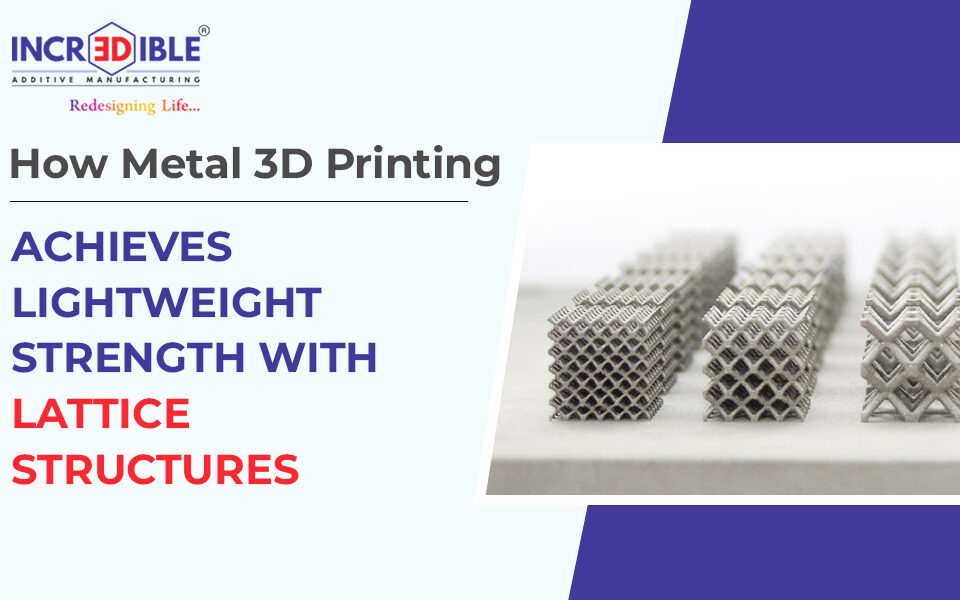

The defence industry can also benefit from 3D printing’s ability to produce freeform, optimised objects. Additive manufacturing significantly reduces the weight of a part and saves material costs and production time. Design engineers use advanced design tools to decrease the number of components and greatly simplify the assembling process.

- Personalized equipment

Besides, allowing for more design freedom, 3D printing offers the opportunity to create customized products that are tailored for specific applications. Instead of carrying parts and pieces for all possible configurations, the 3d printing system is helping soldiers by manufacturing parts on demand. Customisable 3D printable designs are vital to achieving greater levels of agility and flexibility within the military.

- Localized production

Any military budget includes a sizeable portion for coordinating logistics and transportation. The use of additive manufacturing, which prints custom parts, tools, and spare parts close to the point of use, may prove to be more cost-effective for a sector that spends billions of dollars on logistics alone.

This may imply that soldiers stationed in distant locations can also benefit from the use of 3D printing.

Other applications of 3d printing in defence

Modelling, testing, and prototyping: Additive manufacturing is a great way to make quick concept models and prototypes, and it’s frequently used in the defence sector to make prototypes quickly and affordably. It is possible to complete design concepts and validation testing much more quickly, shortening the time needed for product development.

Replacement and maintenance of parts: Military equipment frequently requires replacement and maintenance. For many years, outsourcing was the most popular method for obtaining these components, with thousands of spare parts and tools for military equipment coming from outside businesses. Additive manufacturing brings with it viable options as it makes it possible to produce tools and parts quickly and affordably.

Produces structural components: The process of producing final components for military equipment can be significantly impacted by additive manufacturing. Since the technology can help lower production costs while producing complex lightweight components in small volumes, the defence industry is currently looking into the capabilities of direct additive manufacturing even more. The uses of additive manufacturing in this context are diverse, ranging from intricate brackets and tiny surveillance drones to jet engine parts and submarine hulls. In addition, grenade launchers made from 3D printing are already a reality, and missiles are in the works.

To wrap up

3D printing has the potential to address important defence needs in an environment where the military is becoming more complex. An industry that depends on quick innovation and technological advancements will find additive manufacturing to be the ideal technology because of its quick, localized, and flexible manufacturing capabilities. In the long run, additive manufacturing will make it possible to produce, maintain, and repair military systems and equipment more effectively. This will cause an unprecedented change in logistics and military supply chains.

3D Incredible with its well-equipped facility, latest software, advanced 3d printer, and dedicated and experienced workforce is capable of manufacturing precise geometries in the quickest time. We are a one-stop solution for all 3d printed products and services including the manufacturing of military equipment.

For any queries related to 3d printed products and services, connect with us.