Hydraulic drive is most powerful drive compare to pneumatic, electrical and mechanical drives when it comes for heavy duty applications. The oil is pressurized with the help of pump and directed to various machines and actuators for creating driving force. From pump to actuator, an oil has to pass through various hydraulic components like valves, manifold, cylinders, pipes, filters, chillers, reservoirs, etc. To handle the oil having the pressure of 100s of bars, the high strength components are required. This makes the components much heavier reducing the fuel efficiency of machines. Also the hydraulic components manufactured by conventional techniques has lots of design limitations which affects the flow of oil and performance of machine. The components manufactured by conventional ways are also bulky and heavy in mass which makes it unsuitable for space applications. Conventional manufacturing doesn’t allow to make smooth oil flow path, light weight component and single piece component.

Here comes the role of 3D printing which solves all challenges in manufacturing and design of hydraulic components.

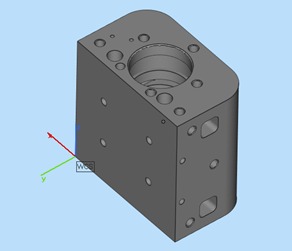

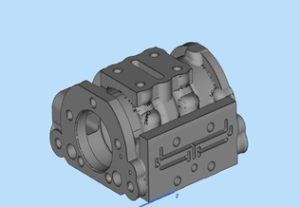

Fig Hydraulic block manufactured by conventional method

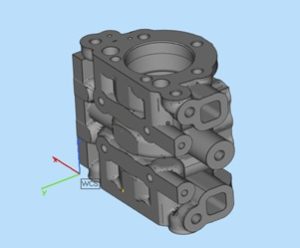

Fig: Hydraulic block made for same application with 90 percent weight saving by 3d printing

- Smooth Flow Paths:

An ability to print complex shape designs enables 3d printing technology to produce valves, and manifolds with short and smooth curvature flow path, than sharp corners. This reduces the pressure drop tremendously and improvises the efficiency by 30 to 50 percent. Sharp corners in flow path create turbulence problems in the system. This is avoided by 3D printing. Also the conventional manufacturing method can only circular cross section flow paths which has limited flow rate. This is overcome by 3D printing which can print channels having square cross section with increased flow rate.

- It reduces the weight and size of the hydraulic components

Fig: Part designed for conventional manufacturing method

Fig : Part designed for 3d printing manufacturing method. 38 percent material and weight saving

In conventional manufacturing, the straight channels are drilled in solid metal block to create the flow path. Hence lots of excess material is left with the block which makes system bulky and heavier. Whereas 3d printing prints the flow path with thickness sufficient to handle fluid pressure which can save upto 60 percent of material in component and also the space. Also the troughoutly drilled channels has to be closed from one end hence plugged. Which after some times start leaking the oil. This is overcome in 3D printing by printing continuous channels in required profile without needing the plugging.

With the help of 3D printing, hydraulic components manufacturers can make parts smaller in size and lighter to handle. This assures lesser usage of metal as compared to the CNC machining. 3D printing also enables compact parts to fit better into the particular designed-constrained spaces. This is an advantage of 3D printing used for hydraulic components as its applications require higher precision & lighter weight.

- Consolidation of Parts

3D printing allows the integration of multiple parts into one making them smaller. This simplifies the complex processes involved with large assemblies of components and also enhances the structural integrity and composition of a part as there are very few joining points that can result in leakage.

- Beneficiary industries:

Many hydraulic component manufacturers look to these technologies for their products as they see the benefits in lead time, weight and cost savings cost and better functionality that 3D printing offers.

Automotive, aerospace, oil and gas industries and numerous other industries who look for smaller, more energy-efficient hydraulic components are the key beneficiary of this technology.

Ford has successfully developed special air intake manifold for supplying air from turbocharger to engine cylinder which was made in just 5 days. UK-based hydraulic systems manufacturer, Domin, has turned to 3D printing to redevelop its high-performance direct drive servo valves, used for transforming signals into pressure, which was made in 60 percent cost saving and 80 percent time saving. A380 tested with 35 percent lighter hydraulic valve block made by 3D printing.

Conclusion-

Looking at the advantages of 3D printing in the lead time, it saves costs, conserves energy, and reduces weight making manufacturing processes function smoothly. It is hence, that many prominent manufacturers are exploring the 3D printing technology for their products. Incredible AM Pvt Ltd India is a leading company offering one stop solution from designing to development of engineering products by metal and plastic 3D printing solutions potentially helping leading companies within the hydraulic industries to keep up with the trends.