3D printed implants are currently commonly used in medicine for a variety of applications like Orthopedic surgery. Its applications range from printing patient-specific surgical models, surgical equipment, and bespoke prosthetics. The ‘patient specific implant,’ which has various benefits for both doctors and patients, is one of the most popular uses. It assists doctors in simplifying surgical operations by providing a perfect fit, while it decreases discomfort and enhances recovery time for patients.

Through enormous example it’s proved that 3D printing is a blessing to medical industry. This article by 3D Incredible AM Pvt. Ltd., discusses how 3D printed implants prove a boon in hip replacement too.

The human hip is a ball and socket joint. It is the most flexible and free-moving joint in the body, and can move backwards and forwards, to the side, and can perform twisting motions. Full function of the hip is dependent on the coordination of bones, muscles, tendons, ligaments and nerves.

Hip pain can be caused by a variety of factors, including:

• An injury that does not heal properly.

• A chronic illness.

• Normal wear and tear from years of constant use.

• Orthopedic surgery

• Severe arthritic conditions, especially osteoarthritis.

• Injuries as a result of trauma, such as a hip fracture or dislocation caused by a fall.

Hip replacement surgery can help you live a pain-free life.

The ability to walk and move without chronic and excruciating pain is the main reason people have Orthopedic surgery –and the main benefit of the procedure. Hip replacement surgery restores movement and activity. After recovering from a total hip replacement, many people resume the activities and hobbies they had before hip pain interfered. They enjoy biking, hiking, swimming, golf and other activities, again. Being able to move with less pain is a definite benefit of Orthopedic surgery. Hip replacement surgery lowers the risk of developing chronic health problems. Being active also has long-term side effects from the procedure.

What is 3D Implant?

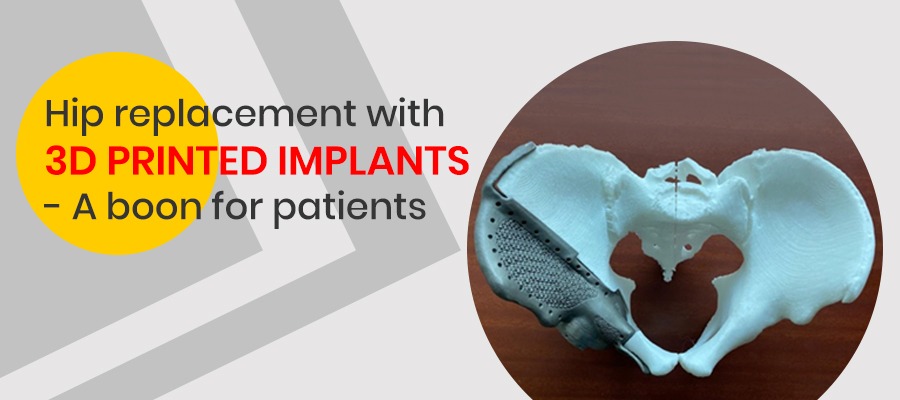

Rapid prototyping, often known as three-dimensional (3D) printing, is a technique for swiftly fabricating a scale model of a physical product using 3D computer-aided design (CAD) data. Since the early 2000s, 3D printing has been employed in the medical business, initially for the manufacturing of patient-specific prostheses and dental implants. 3D printing of a bone model, custom prostheses, and patient-specific tools are among the medical applications of 3D printing technology in orthopaedic departments (PSI). Orthopaedic surgeons may now readily deal with complex Orthopedic surgery by incorporating 3D printing into various situations of hip joint ailments.

Benefits of 3D Implant in hip replacement

1. 3D printing technology can be utilised to manufacture a metal surface with a porous scaffold for custom prostheses. To accomplish a stable biomechanical repair, the porous scaffold allows the host bone to grow inside the construct.

2. Furthermore, non-custom implants can create substantial difficulties due to significant bone resorption due to stress shielding; nevertheless, as compared to a fully solid implant, a fully porous 3D-printed titanium implant can reduce bone loss due to stress shielding by 75%.

3. Using built-in reservoirs and a network of micro-channels, as well as adding antibiotics directly into the polymer during the manufacturing stage, a 3D-printed polymeric implant might operate as a controlled drug delivery vehicle.

4. The shape of 3D-printed prostheses can adjust to different types of diseases without the limitations of traditional prostheses. 3D-printed prostheses, with their outstanding design capabilities, can help when it’s difficult to lay and fasten many traditional prostheses together.

5. Without the use of computer navigation, patient-specific devices can make a speedy and accurate osteotomy, allowing for exact implant matching and reducing operational time, invasiveness, and intraoperative surgeon decision-making.

6. The combination of a 3D printing model for surgical planning, engineering software for implant design and validation, and 3D printing technology for implant and PSI fabrication allows for the development of a personalised, biomechanically evaluated implant for accurate reconstruction following a pelvic tumour resection in a single procedure.

Conclusion:

3D Incredible AM India Pvt. Ltd. has a uncompromising commitment to innovate a wide variety of 3D printing applications. It has the aim to make the world better and healthier. Our state of art plant provides all the facilities that inspire us to utilize the 3D printing technology for the specific and accurate solution for AM technology.

3D Incredible is an ISO 13485:2016 accredited company!