Additive Manufacturing delivers custom-made, flexible, patient-specific solutions for orthopaedics applications. The technology is not only quick and cost-effective but also creates high-quality implants and disposable surgical instruments.

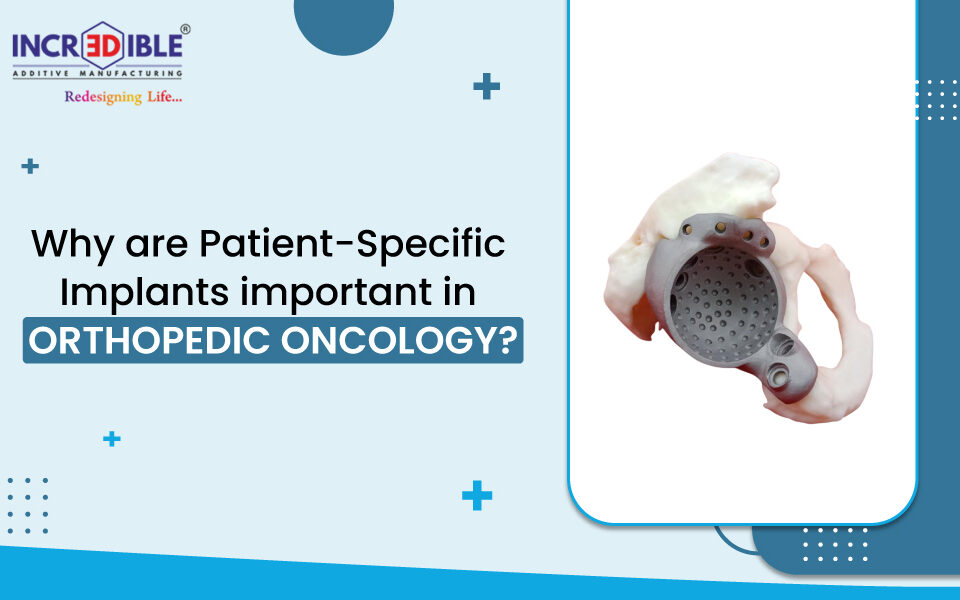

Orthopaedics companies are significantly turning towards 3D printed implants as it solves many present-day challenges of manufacturing of complex countered design implants as a solutions to unique problems, fitting, adaptability, slow recovery process, and hampering penitent’s quality of life. As compared to the traditional process, 3D printing technology has better chances of eliminating these challenges.

Additive Manufacturing has a lot of benefits like creating patient-specific implants, proper positioning of the implants, increasing the success rate. It is also an affordable option for the hospitals because it saves up the costs of extended OT time, surgery time. The production of more advanced anatomical prosthetic and implant is encouraged due to additive manufacturing.

The implants obtained by a traditional procedure like casting require a lot of tools and is expensive for small or unique issues, plus difficult to cast in complex shapes.

One-stop-shop for Additive Manufacturing Solutions is Incredible AM Pvt Ltd that provides patient-specific-implants and service to assist a surgeon to the individual patient in the best way possible.

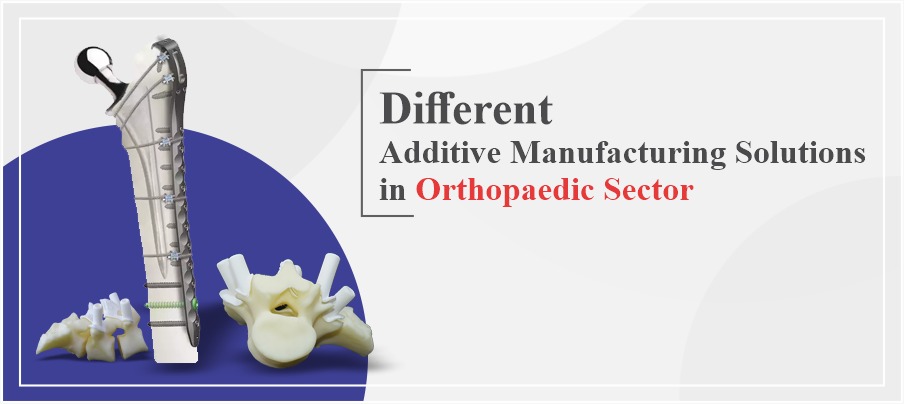

These are the different kinds of 3D printed solutions in the Orthopaedic Sector

The orthopaedic sector relies on additive manufacturing for three major types of implants viz. Joint, Spinal and Trauma. These three kinds are popular due to the current lifestyle and ignorance towards exercises and working out.

Joint Replacement

Joint Replacement is also known as Arthroplasty that is carried out to restore the function of a joint. Most people require Hip joint replacements, Knee joint replacement. The main cause of this condition is the ageing population facing degeneration of joints. The additive manufactures implants provide better mobility and also it is less painful. In addition to better stability during the surgery, with the patient-specific structures, it also initiates bone ingrowth, flexibility, improved alignment, minimal bone removal and less pain.

Spinal Implants

The increasing demand for spinal implants is the consequence of chronic back conditions caused by sitting for long hours in front of the computers in the office. The 3D spinal implants include fusion cages and artificial discs that repair and improve spinal cord injuries, vertebrae, or abnormalities and the replacement of degenerative discs. 3D printed implants are highly biocompatible; it offers numerous spinal column reconstructions.

Trauma Implants

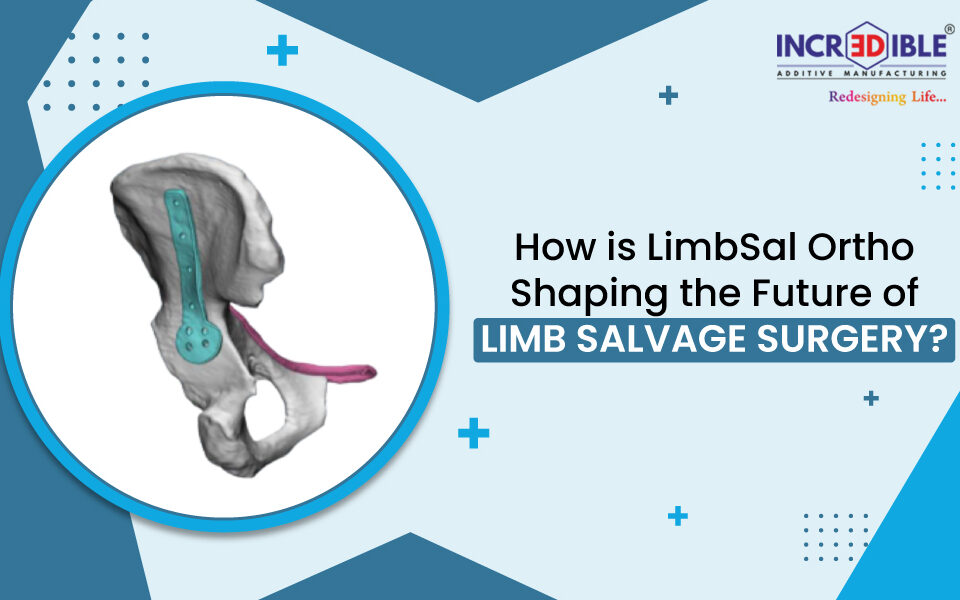

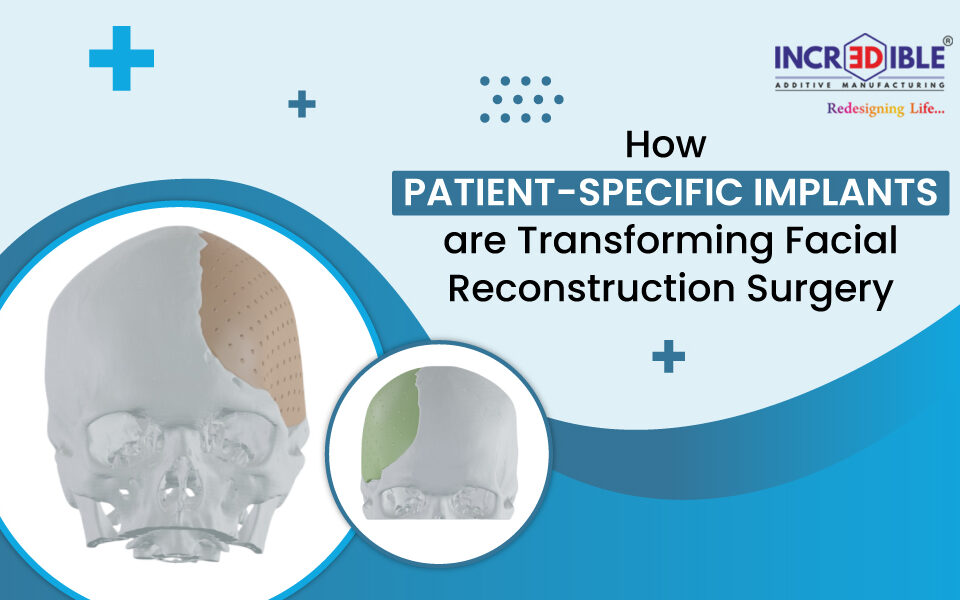

Trauma implants basically imply to the fracture cases which are often caused by accidents. Orthopaedic trauma is usually fixed by internal and external fixation devices. Other surgical treatments that need trauma implants are deformities and tumour diseases of bones like shoulders, legs, arms, or skull. These craniomaxillofacial surgeries are possible because of the optimal size, shape and mechanical properties of 3D printed implants.

Conclusion

Metal 3D printing (Additive Manufacturing) is a new-age technology that can trigger revolutions in the field of medicine, especially, the Orthopaedic sector. Incredible AM Pvt Ltd was established in 2017 is one such company stepping forward in the world of 3D printing. It caters to the unique business challenges in healthcare as well as engineering industries.