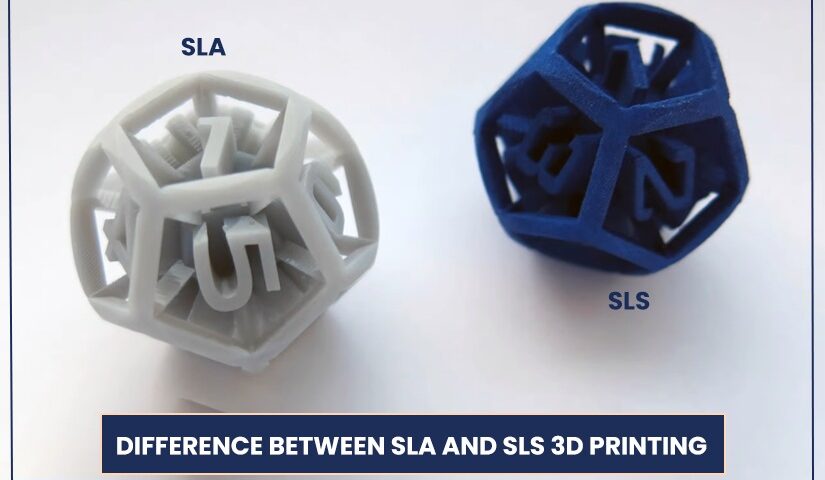

Difference between SLA and SLS 3D printing

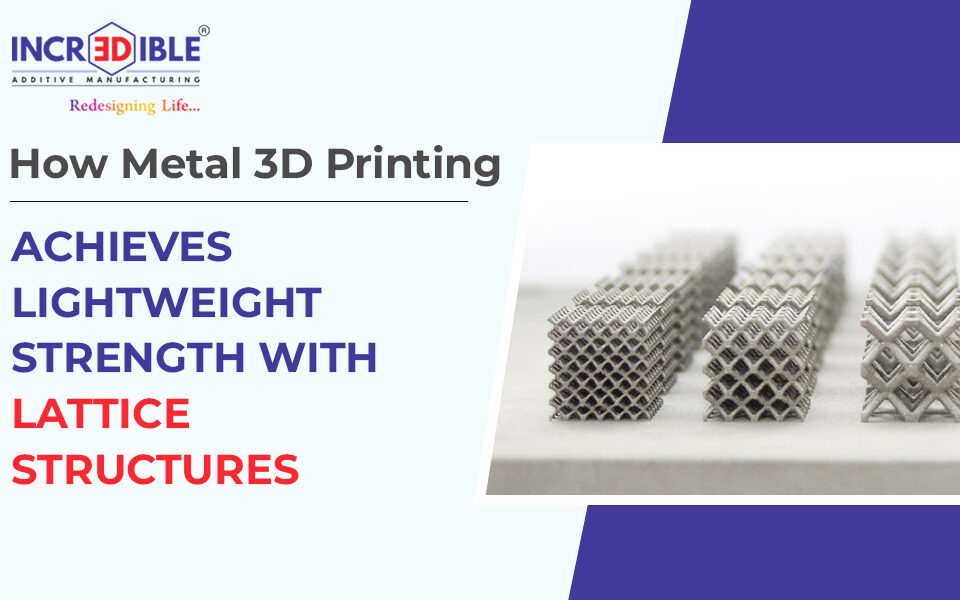

Metal 3D printing, the latest manufacturing technology is transforming the way metal parts are being manufactured. It makes complex and intricate shapes without using dies and tools. It is a ‘Near Net Shape’ manufacturing process where parts are built very close to the required dimensions.

FDM or Fused Deposition Modelling is the most preferred method in 3d printing. It makes use of depositing materials layer upon layer until the final product is obtained. Plastic 3D printing has different techniques such as SLS, SLA, FDM and MJF.3D incredible of Pune has over 40 years of experience in manufacturing and through this blog, we endeavor to bring out the differences between the two most popular techniques- SLA and SLS.

What are SLA and SLS?

SLA or Stereolithography is a 3d printing technique invented in 1986. It is also called photopolymerization as it makes use of a laser beam to draw a 2d section of an object on a thin layer of liquid resin to make a solid layer. The step is repeated and the layers formed are arranged above one another until a complete 3D object is obtained. Once a 3d object is obtained, it is soaked in liquid resin to clean it and remove the support structure that was created in the process.

SLS or selective laser sintering is a 3d printing process most commonly used in industrial applications. The method uses a laser beam to sinter, melt, and fuse particles of powder to form a 3d object. To start the process a thin layer of powder is placed on top of a surface. A laser beam draws a 2d section of an object by melting and sintering the particulates of powder together. Another layer is formed on the previous layer similarly. The process is repeated to obtain a complete 3d object.

How are SLA and SLS different?

Both SLA and SLS processes are popular techniques used for customized 3d printing. They have many points of similarities such as both use laser beam in the process and layers of 2d section obtained are put one above the other. But they are different. Let’s see some of the basic differences between the two processes.

Choice of material

The selection of material is one of the basic differences between the two processes. We saw SLA make use of polymers and liquid resins to obtain 3d printed products while SLS generally make use of ceramics and nylon material, though it sometimes also uses polystyrene.

However, materials used in both the processes have cons as well. The liquid resin used in SLA printing is toxic while breathing in powder particulates during SLS printing may have harmful effects on your health.

Size of the printers

SLA printers are comparatively much smaller and can be used as a desktop machine. On the other hand, SLS printers are larger and are used as benchtop machines. An SLS printer also consumes more power though it prints much faster and builds larger models.

Cost of the printers

You can get an SLA printer at a much lower cost. It can even be less than $500. While SLS printers are expensive. The minimum cost of an SLS printer is $5000. But the materials used in both kinds of printing also differ. A liquid resin used in SLA printers is relatively expensive while Nylon is inexpensive.

Quality of final product

SLA printed products have a smooth finish with highly detailed parts. However, the use of resin makes these strong but brittle. Thus, they become unsuitable for mechanical purposes. On the other hand, SLS printed products though have a rough finish are strong and flexible. They are also capable of creating highly complex structures. Thus, they are utilized for making mechanical products.

Thus, having gone through the differences between SLA and SLS 3d printing methods, you can now wisely make your decision.

Conclusion

The latest technology of 3d printing is finding wide applications in almost every sector. 3d printing is easy, less time-consuming, customized, and above all cost-effective. It is gradually replacing the traditional methods of manufacturing.

At 3D Incredible, we have the latest technology and machinery that is utilized in 3D printing. Moreover, it makes use of the best raw materials from known sources. The company is renowned for the production of high-quality, certified products. It incorporates all the branches of FDM 3D printing technology – SLS, SLA, FDM, and MJF. This makes the firm the best destination for all your 3d printing requirements.