The conformal cooling system made using 3d printing is a working solution with proven benefits for injection moulding. Additive manufacturing is witnessing a rise in popularity as a manufacturing technology. For the toolmaking industry, one of the most important markets, the conformal cooling system is regarded as one of the first real commercial applications of the latest manufacturing technology. 3D Incredible AM Pvt Ltd, headquartered in Pune, India, is a pioneer in the field and offers high-performing injection moulding tools for customers by utilizing additively manufactured conformal cooling solutions. Here, in this blog, we will learn about the advantages of conformal cooling with 3d printing.

What is conformal cooling?

For the plastic injection mould tools that closely follow or conform to the shapes of the parts to be moulded, an efficient cooling channel is of prime importance.

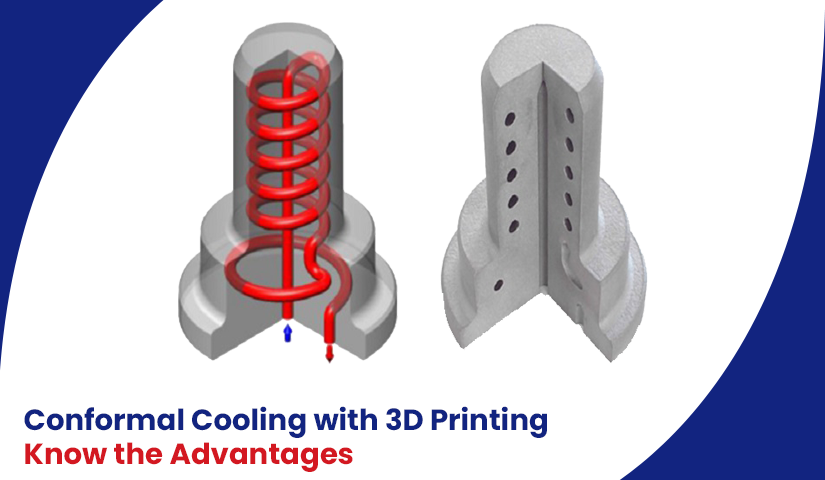

For a long time, the traditional cooling system consisting of a straight line cooling channel located in the midway of the object, irrespective of the shape of the object has been used. The conventional cooling system has inherent limitations. It often fails to provide uniform cooling in the mould cavity. The complex geometry, curved surface and varied thickness of the wall of the plastic parts pose difficulty for uniform cooling. Thus, it leads to inconsistent results and adversely affects the manufacturing cycle.

Conformal cooling channels, made using additive manufacturing technology, are effective in eliminating the limitations posed by conventional cooling systems. These customized 3d printed conformal cooling channels are designed according to the internal shape of an injecting moulding object. They are produced in a variety of cross-sections – rectangular, circular, semi-circle, elliptical, etc. that is exactly according to the moulded objects.

Moreover, the cooling passageway of such cooling channels is designed to follow the shape of the cavity and mould course. This helps in bringing about temperature uniformity that facilitates the rapid cooling process during injection moulding.

Advantages of 3d printed conformal cooling

The success of a manufacturing industry mainly depends on the time taken to manufacture products and on attaining the high quality of the products. Conformal cooling with 3d printing is helping the tool industry on both of these fronts.

Cooling mould parts is the most time-consuming part of the injection moulding process. Time reduction for part cooling increases the production process and hence there is an increase in the production cycle.

With the modern and improved cooling method, conformal cooling speeds up the cooling process of the mould parts and hence drastically reduces the cycle time, in some cases even up to 70%. In addition, this technology also benefits by

- Improving product quality with an excellent surface finish and accurate dimensions.

- Reducing warpage and wastage

- Reducing labour, number of machines, space and energy.

Thus, a conformal cooling system with 3d printing helps in the improved productivity, efficiency and reduction of overall production cost. To enhance the effectiveness of your business, it’s wise to switch to a novel method of the cooling system. Incredible AM is your trusted partner to provide 3d solutions for your business requirements.

Conclusion

Incredible AM Pvt Ltd located in Pune produces 3d printed conformal cooling channels to provide you with an improved manufacturing method. Our state-of-the-art manufacturing unit helps us to produce the best results and deliver the product in the shortest time interval. For over 45 years, we have been satisfying our clients with high-quality products and the best services. For the requirements of conformal cooling with 3d printing, do contact us.