The technologies such as Additive manufacturing, medical patient specific implant manufacturing also known as 3D printing are robustly growing in the healthcare industry. Some of the well-established processes in the surgical fields include 3D virtual surgical planning, fabrication of anatomical models, and patient-specific implants (PSI).

Reconstructive surgeries can be extremely challenging even to the most experienced surgeon especially due to complex anatomy. The sensitivity of the involved systems, and the uniqueness of each defect. Patient-specific implant (PSI) can be an effective solution in this situation as it mimics anatomically to the patient’s defected area.

We at 3D incredible, starting from the patient’s CT data, provide anatomically shaped patient-specific implants to reconstruct skeletal defects or enhance skeletal features. hence providing precision in aesthetics and functioning. The need to fabricate the PSI has led to many innovations and technological advancements in the medical field. Our custom implants, optionally combined with bio-models will surely benefit both surgeon and patient.

Benefits of Patient-Specific Implants:

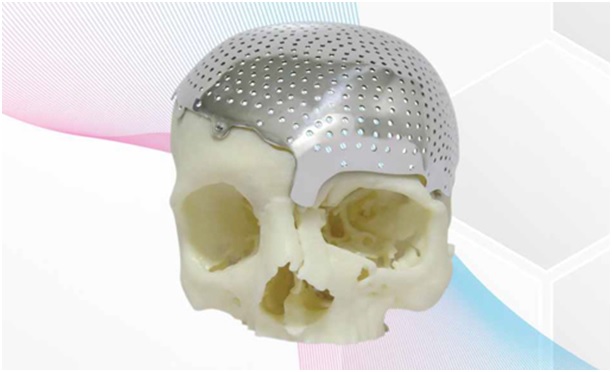

There are multiple benefits of manufacturing patient specific implants using 3D metal printing for the surgeons as well as patients. Patient specific implant manufacturing or 3D metal printed PSI offers better anatomic fit, reduced operating time, and satisfying aesthetic results compared to conventionally manufactured PSI. Customized implants allow surgeons to reconstruct the defect in the best possible way along with time minimization for improving patient outcomes and well-being. The PSI also allows producing complex anatomical shapes, meshed or porous structures. Virtually any design feature is possible using 3D metal printing, which is always a limitation in case of conventionally manufactured PSI. Take a look of some 3d metal printing application in the medical industry.

Types of Patient Specific Implant Manufactured by 3D Incredible:

There are various types of patient-specific implants manufactured by 3D Incredible that has helped numerous surgeons and patients. The different types of implants are Cranial Implants, Maxillofacial Implants, and Orthopedics’ Implants.

Cranial Implants:

Cranial reconstruction is required to restore the skull contour and to protect intracranial structures and normalize the cerebral hemodynamics. Our UltiFit-Customized Cranial Implant helps in providing exact symmetry & maintains original aesthetics. In neurosurgery, the use of these implants and prostheses is very important, as skulls have irregular shapes and it is hard to standardize a cranial implant. To meet these design & functional requirements, we at 3D Incredible use patented design specifications to design 3D implants.

Maxillofacial Implants:

Maxillofacial implants are the implant used to reconstruct the missing bone to provide the benefit of both functioning and aesthetic. Our Confidence – Mid Face implants are designed in a way to provide the minimum thickness as low as 0.7mm so as to reduce weight and also to reconstruct the complex structure with world class US FDA and CE approved the software.

Our Confidence – Mid Face product range has been developed to suit wide indications for the reconstruction of various facial anatomies like maxilla, orbit, mandible, and zygoma. Besides this, we also offer complete end-to-end solutions for orthognathic surgeries and free flap fibula graft cases.

Orthopedic Implants:

An orthopedic implant is a medical device manufactured to replace a missing joint or bone or to support a damaged bone. This medical implant is mainly fabricated using stainless steel and titanium alloys for strength and the plastic coating done on the exterior part act as artificial cartilage. In orthopedics standard implants are often not sufficient for some patients, particularly in complex cases and thus, these quickly produced custom implants and prostheses solve a huge problem.

Conclusion:

3D incredible work in hand with the largest group of skilled and experienced software developers and mechanical engineers who turn the vision into reality.

With extensive experience in CAD and having equipped with the latest 3D technologies, we can supply you with a wide range of patient-specific implants, based on anatomical data from the patients and your requirements as a surgeon.