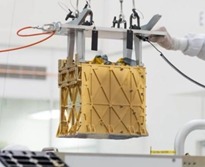

3D printing is very useful for aerospace industry in many aspects. Indeed, it could become a major asset for space travels in the future. Researchers are also finding different applications to this cutting-edge technology in space. 3D printed parts are sent to space, but some technologies, able to 3D print directly in microgravity or in the vacuum of space are also being developed. Additive manufacturing “for-aerospace” and “in-space” is a real blessing. With its various advantages, 3D Incredible is been contributing in increasing use of 3D printing in space industry.

Fig. 1. The SpaceX rocket engine using the 3D printed oxidizer valve during a test phase.

Fig. 2. The 3D printed SuperDraco rocket engine by SpaceX.

Fig. 3 NASA 3D printed MOXIE experiment makes oxygen on Mars

What are the benefits?

Boon in aerospace technology: The additive technology used to upgrade aerospace technology could simplify logistics. Ability to create high strength to weight components allow to create satellite structures.

Prototyping saves experiment gaps: A functional prototype created by 3D printing would save a lot of time. Working on 3D printers that are functional in space, working with the FDM (Fused Deposition Modeling) technology will contribute towards saving time lag between the experiments. Cost effective for less quantity production enables large saving in Research and development compare to conventional manufacturing techniques.

Material: The vast alloys available to print in 3D printing helps to serve not only the turbine, marine, automotive but also the space sector. Inconel, Titanium, Aluminium, Copper and Ferrous alloys in addition with carbon fiber composites makes 3D printing technology best suitable for space sector. Near net shape production achieves great accuracy and quality of components can easily serve space industry requirements.

Minimize the wastage: wastage in aerospace industry can cause loss of millions. 3D printing helps in bringing precision in designing, and reduced wastage of the costly material used. Being India’s 1st and exclusive 3D Printing Company to have ISO 9001 Certifications, 3D Incredibles focuses on good manufacturing practices to reduce wastage. This further leads to contributing towards environmental precautions.

Helpful in Daily life of space-goers: Using this technology will help significantly the astronauts in their daily life in orbits during space explorations. The tools or parts they need to replace during their space travel becomes a pain as it can be long and expensive to send them what they need. They could simply 3D print it. It is the same thing if a tool is missing. It would be so much easier and time-saving if they could just 3D print their screwdriver when they need it!

Conclusion:

The aerospace industry is a major segment to benefit from 3D printing. It has an extraordinary requirement of auxiliary parts. 3D printing gives the manufacturers, complete flexibility to prototype specific aerospace parts. And those can be produced in hundreds or thousands of pieces without any expensive tool changes. 3D printing also improves engineering and manufacturing competences of tools which are needed to create these parts. It can also facilitate light weight aerospace structures. 3D Incredible’s services contributes in the aerospace industry by helping fuel savings and reducing environmental impact.