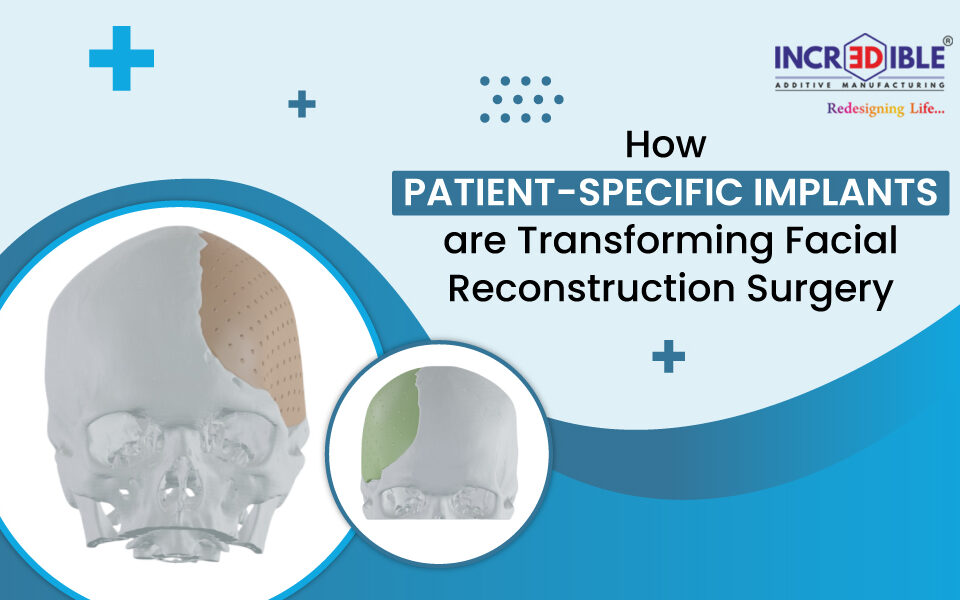

The arrival of 3D printing technology changes how oral and maxillofacial surgeries should take place. Surgical procedures in this field deal with difficult facial structures, so correct placement is necessary to deliver success. Doctors now manufacture unique OMF Implants using 3D printing technology to serve each patient. The custom process fits better with the treated tissue, and shorter surgical time produces fewer postoperative problems. The technology lets doctors produce implants and repair facial bones more accurately for their patients.

Personalized Implants That Fit Perfectly

Traditional implant designs fit only basic bone patterns since each patient’s bone shape varies. By using patient scans from CT or MRI machines, 3D printing creates OMF implants that match perfectly the intended position. This technique provides perfect pain relief and strengthens the repair process while letting patients recover more quickly. Because the implant perfectly fits the bone structure, the doctors can spend more time performing the surgery without reshaping efforts. The exact matching of the bones produces superior performance and produces results that keep going for a long time.

Enhancing the Surgical Process

The biggest advantage of using 3D-printed implants is that it helps surgeons work better during operations. They produce three-dimensional prints of the patient’s anatomy, which assists surgeons in practicing the operation ahead of performing it in real procedures. The technique provides surgeons with greater assurance for their work and makes them perform maxillofacial implants faster with fewer mistakes. The technology delivers custom-made implants to their exact placement position. The shorter surgical duration helps patients heal faster because it decreases their infection risk along with lowering their need for anesthesia and recovery time.

How Does 3D Printing Support Innovation in OMFS?

3D printed implant benefits doctors and researchers in both present surgery practice and future medical development. It permits medical professionals to evaluate different implant variations before investing heavily in development. The ability to change implant production methods and usage stimulates medical development. Doctors can test combinations of biocompatible materials and light metals, which make implants more comfortable and reliable for patient use. Study progress brings us closer to receiving better minimally invasive implants that repair severe facial damage better.

Can Patients Expect Better Recovery?

Yes. Customized 3D printed implants help patients recover more easily because they match perfectly to their bodies. The support from surrounding tissues becomes lighter, which lowers the risk of postoperative problems, including swelling and discomfort. Patients find they can do their regular activities, such as talking, eating, and displaying their smile, sooner than before. Special implants designed for each patient help them regain natural-looking facial aesthetics to rebuild their self-assurance. 3D-printed OMF implants deliver all essential benefits for the extended healing of patients because of their combined benefits.

Conclusion

Using 3D printing technology makes OMF implants better meet surgical needs for both appearance and functionality. The combination of digital surgery tools and medical care brings the best results while delivering accurate treatment to patients. Check out 3D Medical for tailored surgical solutions because they are the top technology provider in personalized implants.