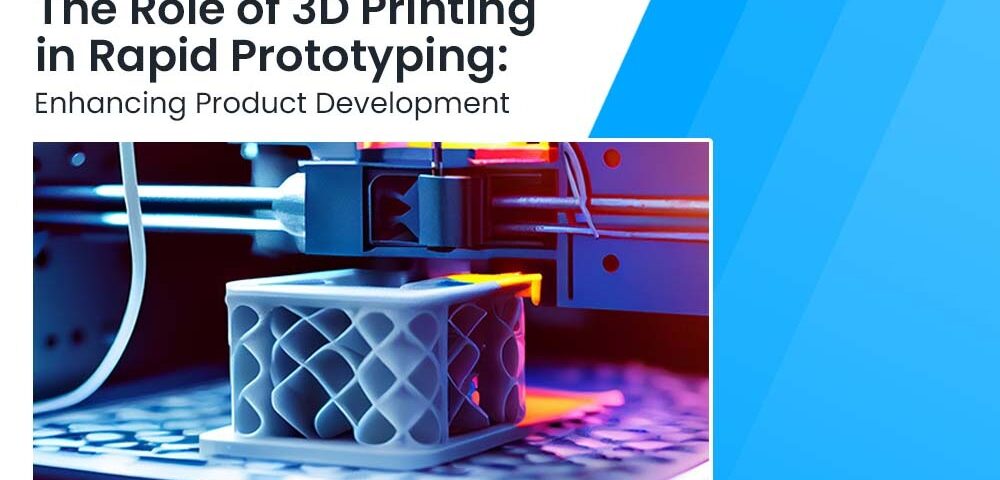

The demands of globalization and technological advancement mean that today’s organizations can only afford to introduce new products in the market in shorter cycles. Now they still require effective solutions for rapid development and manufacturing of small batches of products. This is where rapid prototyping becomes useful by providing a mechanism of manufacturing that requires minimal tooling and setup. With the use of rapid prototyping, firms can develop dynamic operational mock-ups based on digital models with less time and less money than traditional methods. One major technology that fuels this revolution is 3D printing, a tool that has revolutionized how organizations physically realize their visions.

Prototyping in the Product Development Process

Prototyping is the most effective step in the product development process since it helps the designers and engineers make a real model upon which they can assess the suitability of the product before manufacturing it. They help one determine the efficiency, user-friendliness, and effectiveness of a particular product. Prototypes can be created from a raw material, for instance, clay, foam, or plastic, about the requirements of the specific product. This process allows teams to pinpoint problems that may cause the quality of the product to be compromised or misunderstandings that may force unnecessary changes in the production line, thus providing customers with quality products that meet their needs fully.

Reason for choosing 3D printing in product development

3D printing rapid prototyping offers several advantages in product development. It drastically cuts time to market, to start. Designers may go straight from a digital design to a real prototype with 3D printing, as opposed to traditional manufacturing, which requires the creation of molds and tooling. Businesses may launch products more quickly thanks to this short turnaround, giving them a competitive advantage.

Testing and Evaluating Functionality

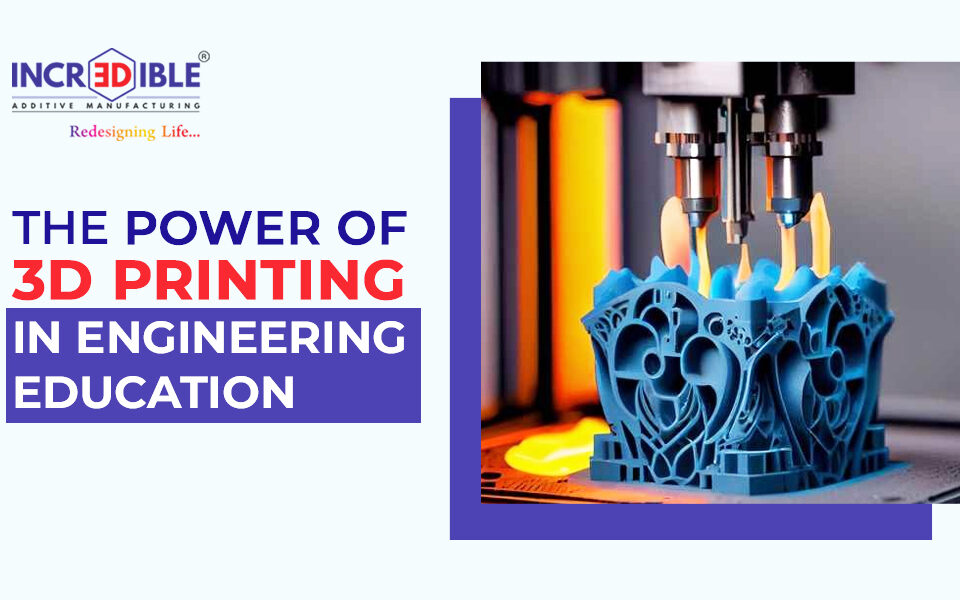

If implemented effectively, 3D printing enables designers and engineers to design and build working models that mimic the creation’s behavior. This allows for detailed testing to take place with a view to identifying certain complications in the design before mass production is commenced. Through applying functional prototypes, teams are also able to figure out the product functionality or strength and improve on the designs; without such enhancements, they are made at later stages, negating the outcome of expensive rectifications.

Flexibility

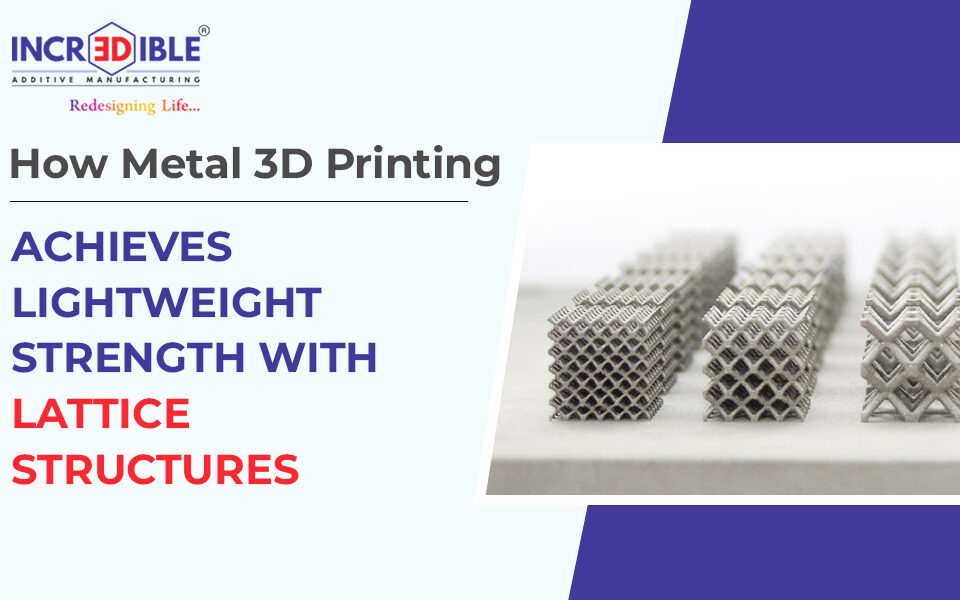

With traditional approaches, designs are restricted, but with 3D printing, fancy geometries, and fine features are possible. This technology has new opportunities to develop; it is possible to produce thin-walled structures, complex patterns, and unique single components that were previously not feasible.

Carry less risk

When using the idea of 3D printing upon making the prototypes, the risk is comparatively low given the fact that it is faster and more efficient when it comes to designing and testing. Usually quick delivery means quicker reviews and feedback, which is important considering designers can make any needed changes early in the process. Due to the collaborative process with marketing and quality assurance, product designers and engineers can fine-tune the final designs. It is therefore quite clear that a collaborative effort between different teams leads to the creation of more successful products with rapid prototyping.

Considerable cost savings

3D printing is cost-effective in a material sense. In conventional manufacturing settings, tooling can be very costly, which could pose major problems for firms operating under tight capital. Still, when coming to options for product development, 3D printing has a clear advantage as it does not require the use of tooling at all, thus saving much in upfront costs.

Conclusion

Using a 3D printing rapid prototyping tool is one of the most effective ways to boost a company’s productivity and speed up work for people who want to design new products. All the services required to make the prototyping process as efficient as possible are offered by 3D Engineering. When developing ideas, one can directly apply them to manipulation with the help of a 3D printer and later produce them, making it easier in terms of time and cost. It may be expensive to operate and require a technical team, but 3D printing is still a revolutionary asset to the product development process.