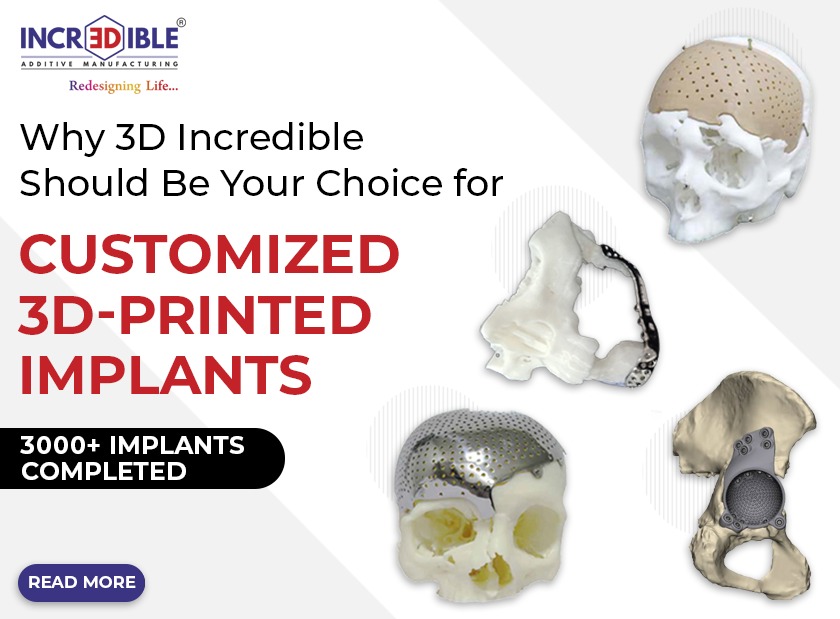

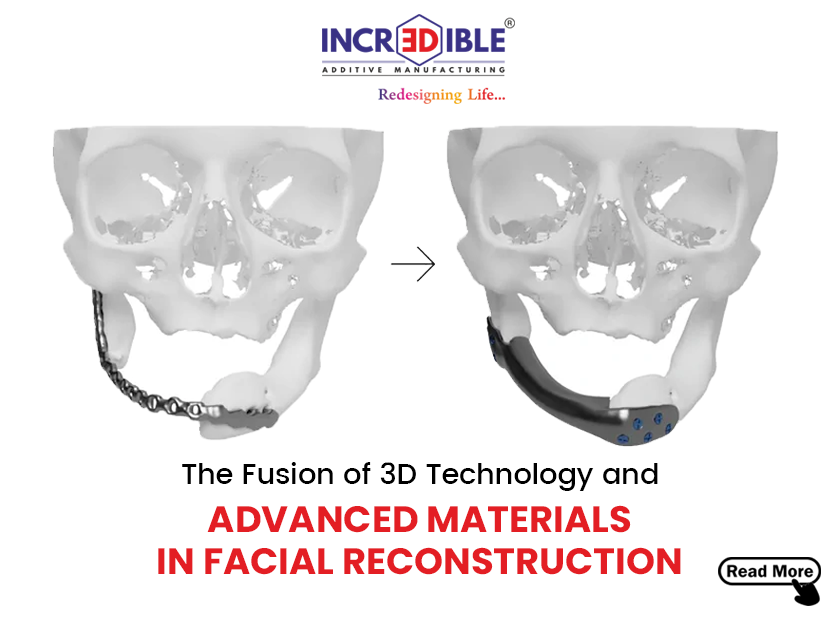

Reconstructing deformities is quite challenging for most surgeons due to the complex anatomy and cosmetic and functional effects of such deformities on patients. The use of pre-made alloplastic implants and autogenous grafts is often associated with resorption, infection, and displacement. Recent technological advances have led to the use of patient-specific implants (PSIs) in reconstructive surgery. These implants are manufactured using additive manufacturing technologies. Manufacturing such customized implant or patient specific implant (PSI), sounds to be a costly and difficult task, but 3D Incredible has overcome the hurdles, and finally, is been successful in achieving patient satisfaction.

This upgradation in technology is largely drawing attention of majority of the surgeon community due to its enormous advantages over the traditionally manufactured ones. But, woke surgeon shall keep few things in mind while selecting the products for his/her patients, such as….

1. Is the implant you are using came from ISO13485 certified manufacturer?

Manufacturers in the medical industry are expected to regulate their quality management processes and ensure best practices.

3D Incredibles is a pioneer in fulfilling these internationally accepted standard for a quality management system specific to the medical devices industry. It is India’s 1st and exclusive 3D Printing Company to have ISO 9001 and ISO 13485 Certifications.

2. Are you using certified biocompatible implant?

Several studies have suggested that not all patients can tolerate metallic implants containing nickel or cobalt. They exhibited several immunological responses. Therefore, though additive manufacturing doesn’t use these ingredients, it’s always advisable that while choosing a patient specific implant, you should be ensuring that the material is biocompatible.

3. Is your implant designed using licensed materialize software?

Piracy leads to limitations. To develop a perfect fit skull implants or cranial implant, a world class software is needed. A 3D Printed Implant needs to be a perfect fit as it is custom made and patient specific implant. 3D Incredible uses all top quality software. A licensed 3-matic, quantum, NX, magic software’s are used for designing

4. Is your customized implant manufactured in a controlled atmosphere?

While dealing with human lives, at most hygiene is supposed to be maintained. 3D Incredible maintains a class 10000 clean rooms to achieve the control atmosphere required to give you a perfectly hygienic 3d metal printed implant.

5. Is your customized implant validated successfully through the quality tests?

A car when approved for its safety has to go through several quality parameter tests then why not your patient specific implants? Make it a point to ask the manufacturer for results of bend test, fracture test, stress test, load bearing test before buying any 3D Printed Implant.

The 3D incredible plant is built as per FDA guidelines of 14000 sq. ft., our products go through Tensile Testing, Bioburden Test, Density Measurement Test, Biological Evaluation Test, Stability Test, and Chemical Analysis Test before reaching to your operation theater.

Conclusion:

The use of computer-designed PSI enables a more accurate reconstruction of deformities, eliminating the usual complications seen in preformed implants and resulting in higher patient satisfaction. But if you are planning to use customized or patient specific Implants, then you should definitely ask for the five things mentioned above.

As per the regulations, customized implants can be manufactured and implanted only against prescription from a surgeon, and hence choosing one becomes sole responsibility of yours. Therefore, a quality pro organization like 3D Incredible, assures that a best quality, hygienic and standard product reaches to your customer!