The advantages of 3D printing technology make it one of the most promising technologies to replace the traditional automotive manufacturing practices in the near future. The 3D printing technology is growing quickly in various industries, which appears to be a result of increased awareness and acceptance of the technologies among business leaders and engineers.

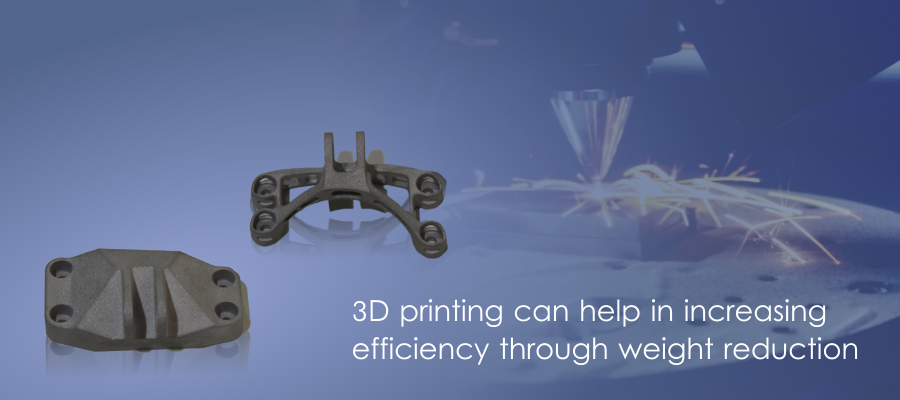

3D printing is already being used by automotive OEMs, including car, motorcycle, and CV manufacturers to transform the way they visualize, design, and build products. 3D printing has several advantages and increasing efficiency of parts through weight reduction is one of them. This is a real advantage in industries like Aerospace, Defense, Automobile and Medical.

Role of 3D Printing in Increasing Efficiency through Weight Reduction:

3D printing offers some great advantages for applications where you can change the part’s weight by in a manner so that the strength of the part is maximized but weight is minimized. Reduction of material from a part without compromising mechanical properties is a challenge, however metal 3D printing has enabled us to reduce a part weight through innovative lattice structures and honeycomb structures.

Lattice structures can be used to achieve excellent performance and multi-functionality while reducing the weight of parts. This concept comes from the desire that the functional area of part doesn’t gets disturbed and material is structured in such a way that it can sustain heavy load at the lowest weight thus giving high strength & low mass property. The free-form capability of additive manufacturing enables engineers to remodel their designs with lattice structures and manufacture them with ease.

Weight reduction is really important in the aviation industry, where a reduction of one kilogram in an Airplane can help fuel savings of up to 3000 USD per year. In the automotive industry, reducing cars weight contributes to fuel economy and lower CO2 emissions. Various studies have shown that a 10% reduction in weight can save around 6-8% in fuel consumption.

Conclusion:

3D printing has gained wide acceptance in the aerospace and medical industries for its weight reduction properties, while other industries such as defense & automotive are working intensively to adopt this technology for increasing the efficiency of vehicles.