The Medical sector has become ever-dynamic with the advent of technology and the implementation of 3D printing. Metal 3D printing has made it possible to create customized solutions for the ease of surgeons as well as patients. It has made the surgeries faster and easier with the concept of rapid prototyping. One of the biggest reason is the reduced development time and accuracy in the process.

As per a report by Wohler’s (2015), Medical sector is the largest consumers of the 3D printing industry and contributes 13% of the total revenue. Many different solutions like standard implants, bio models, surgical guides, and customized implants are offered by the 3D printing companies.

Additive Manufacturing has enabled quick creating of novel instrumentation in affordable prices. With Incredible AM’s instruments enable smooth and quick surgical procedures. These Patient-Specific Instruments are made using Titanium, Stainless Steel, and Cobalt Chrome.

What are Patient-Specific Instruments?

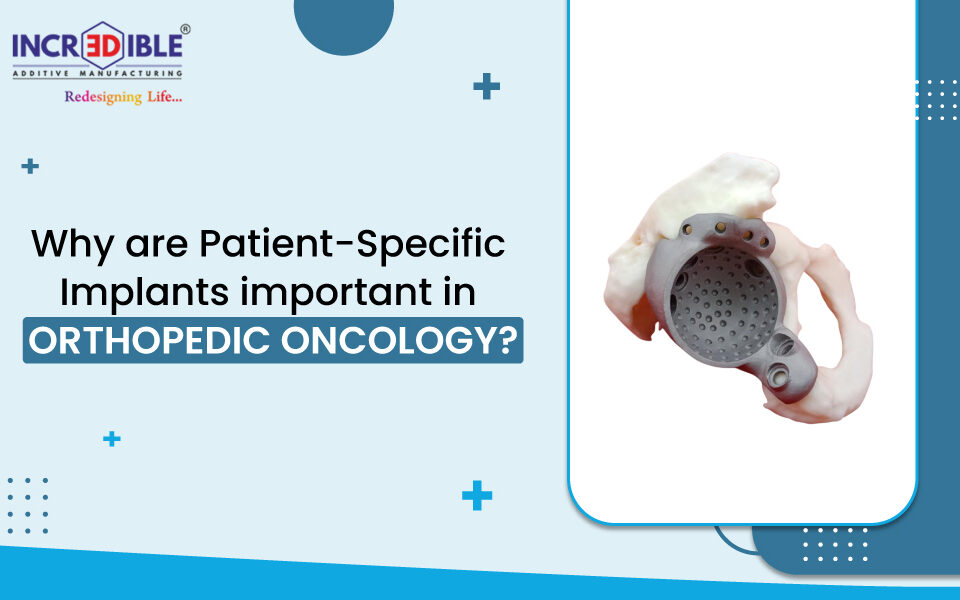

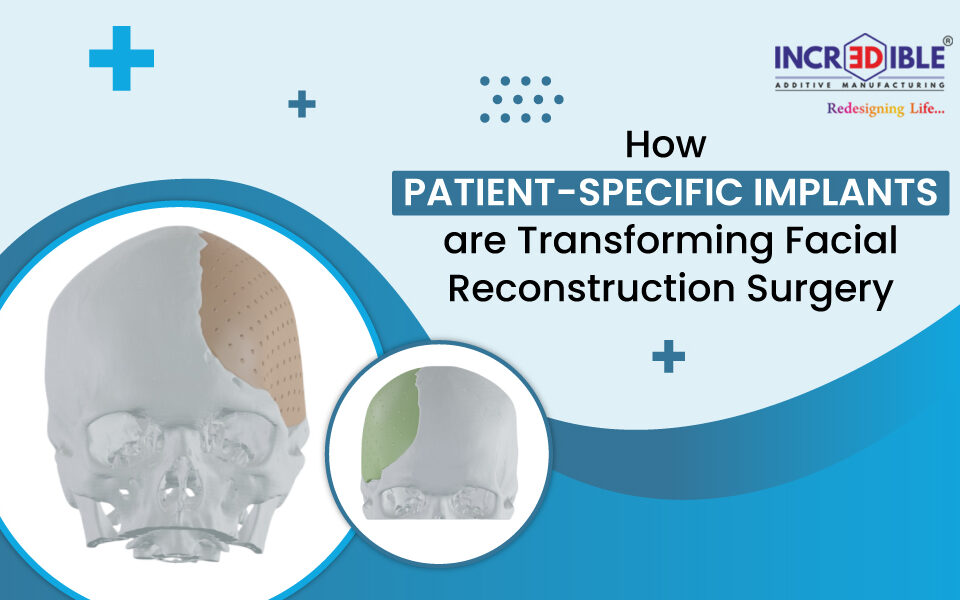

The Patient-Specific Instruments are basically customized designs of anatomies or models. These designs are created on the basis of the patient’s imaging data using image segmentation. The designs are then fabricated by additive manufacturing for medical applications. The aim of using this tool is to replicate surgical plans involving guiding and drilling in a specific planned direction.

The PSI is used to correct deformities or fracture malunion, in addition, it is recently being used for bone tumor surgeries. Since these are personalized instruments and require minimal operative setup, it makes the surgery easy and faster.

What are the Aspects of Patient-Specific Instruments that Enables Easier and Faster Surgeries?

Minimizing Complexities:

The contour, organic shape, and complexities are kept in mind while creating the PSIs. This has opened doors for many complicated surgeries to take place easily.

Customized Solutions:

As every patient’s health conditions and anatomy requirements are different, their solutions should also be different. Therefore 3D printed instruments are ideal for manufacturing PSIs catering to the unique problems of each patient.

Sterilizable Instruments:

Sterilization and sterilization compatibility are important material properties if we are considering it for medical applications. Hence, materials like cobalt chrome, stainless steel and titanium are used.

Decreasing the Lead Time:

The hallmark of 3D printing technology is that it allows the designers and engineers to create PSIs quickly using the realistic prototypes and in turn reduce market time.

What are the Applications of Patient-Specific Instruments?

- Imp

- Customized implant placement guide

- Screw fixation guide/drilling guides

- Bone resection guide

- Tissue aligning jigs/guides

Why Choose Incredible AM for Your Patient-Specific Instruments Needs?

- Company is having rich experience in manufacturing of patient specific surgical guides/jigs and patient specific implants.

- Company have done more than 300 such complicated surgeries successfully.

- Company is using world class high end USFDA and CE certified softwares to design such products results with high precision.

- The company has state-of-the-art plant with world-class manufacturing set-up.

- It has a team of experienced and engineers and professionals.

- It is featured with perfect designing and software skills.

- They use bio-compatible materials for creating tools and implants.

- The company’s lab is equipped with ultra-modern instruments.

- The company’s manufacturing process is ISO certifications like AS9100:2016, ISO 9001:2015, ISO 13485:2016.

- Their manufacturing process includes, converting CT scan dicom the imaging information into 3D models, creating designs of the implants, and lastly making 3D printed implants.

- They follow all the CT Scan Protocol.

- The company also follows all the required tests and validations.

Conclusion

3D Printed Patient-Specific Instruments have revolutionized the medical sector. The most reliable source of Patient-Specific Instruments is Incredible AM. The company provides quality, durable and affordable products.