For a technology that has not yet managed to reach any hospitals or healthcare organizations, 3D medical printing is well on the way to dramatically impacting the industry. The technology is now flourishing in the healthcare scene, amid a lack of mainstream acceptance, enabling complicated procedures such as the recent separation of twins with conjoined hearts by the use of 3D-printed models and virtual reality, a surgery for which no survivors were previously reported.

At the moment, there is a great deal of investment in 3D printing and there are some very simple ways that the technique can be used to strengthen current processes. There are places where you can decide where you can potentially save resources, increase recovery, minimize suffering, improve patient acceptance by using a 3D-printed substitute for the existing technique, both optimistic motivating forces that make the industry move forward.

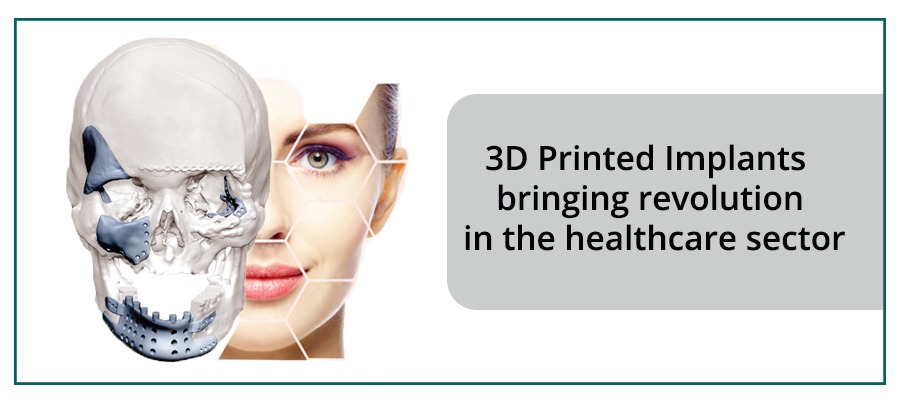

3D Printing in Healthcare Means Comfortable, Cost-Effective Implants

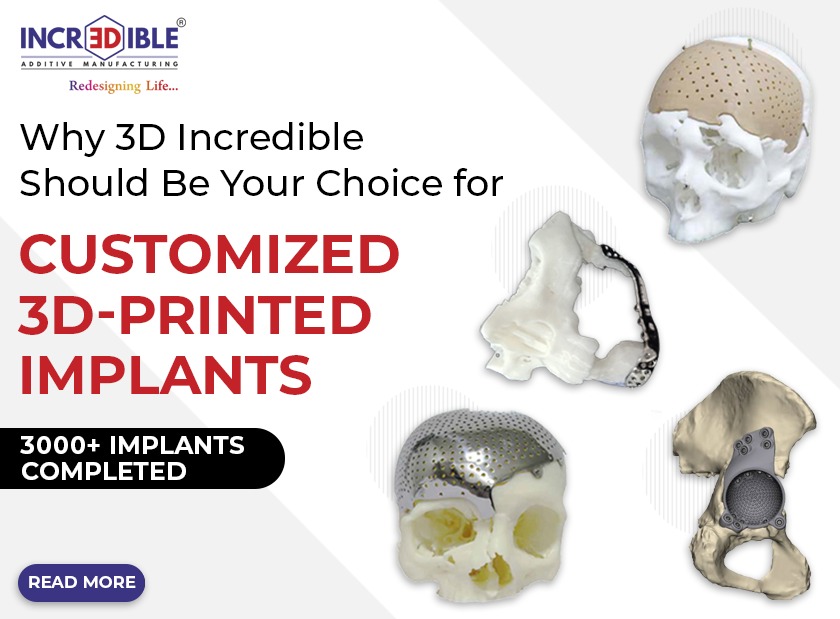

In the field of prostheses and implants, 3D printing in healthcare is already showing its importance. Incredible 3D splurge plans for 3D printers, tools, and training to facilitate the creation of custom orthotics, prostheses, and anatomical templates for customized healthcare. The network is built to have a positive effect on doctor preparedness, surgical teamwork, and, in turn, patient treatment and more streamlined costs by expanding access to 3D medical printing.

The goal for 3D printing is to see uniform availability at all hospitals around the country accelerating the production of customized healthcare, equipment, and technology for veterans and their families. 3D printing in medicine can not only help create personalized instruments and devices for patients with prostheses but can make the actual prosthetic system even more comfortable and functional. You may precisely build a replacement like a hip or a skull implant or any appropriate external replacement for anything missing in the body to suit even more than an off-the-shelf product by using imaging equipment directly from the patient.

As a result, surgery time will be much quicker, healing time will be much faster, and you will feel less pain. It turns out, in most cases, for the patient’s benefit. In comparison, 3D bone and organ printing can definitely be considerably more cost-effective. In the past, the construction of a prosthetic to repair a damaged hand could cost patients and the healthcare system tens of thousands of dollars or more. With the introduction of 3D printing, at a cheaper price, you can now print a prosthesis. This has an especially poignant application for kids with prostheses, who every few months outgrow the prosthetic devices.

What 3D Printing trends are bringing a revolution in the healthcare industry?

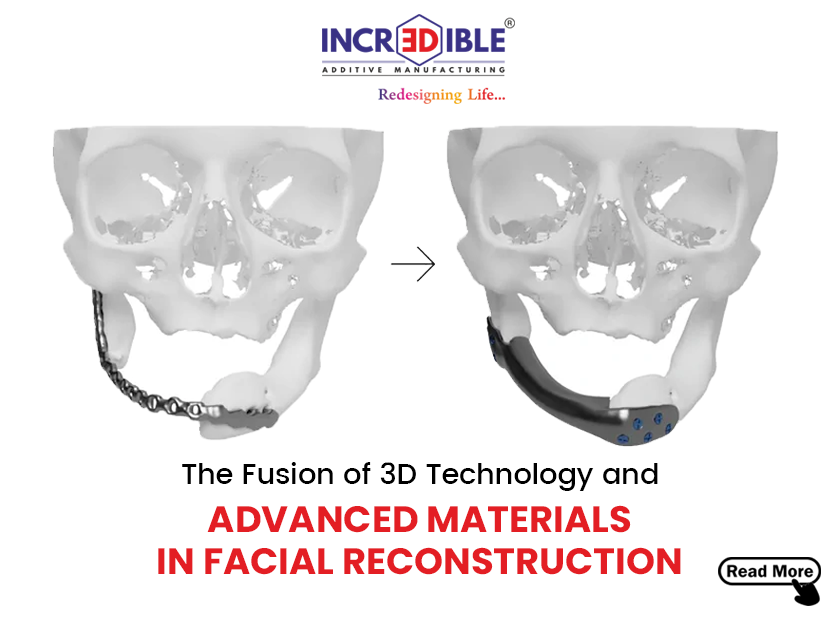

In refining the design of implants and devices, the medical device industry is beginning to truly appreciate the potential of 3D printing. To minimize the number of manufacturing steps and components in a system and thereby reduce the total cost of making a device or an instrument, the industry is seeking to harness the potential of additive software and hardware.

Such trends indicate that 3D printing technologies should be able to harness the strength of the healthcare sector to drive creativity and to deliver innovative goods to the market to optimize patient care.

Right now, we can see this revolution emerging in the spine industry where the interbody fusion systems used to be constructed almost entirely of used components such as PEEK and assembled using conventional subtractive processing methods. But now 3D printing is being introduced by the spine industry to develop new innovative products that can facilitate bone in growth and thereby enhance the fixation of implants to the host bone. Printing these machines also decreases the number of processing phases, and in many situations makes the additive operation more cost-effective. It is an innovative concept to drive creativity to deliver highly efficient products at reduced total prices that will increase the quality of treatment.

Conclusion:

Despite the apparent advances that 3D printing has made in medicine, problems exist. The development of materials that can be deposited using 3D printing is at the crux of holding back the spread of this technology. But with strong science and money pouring into space, groundbreaking products are expected to come onto the scene over time. In particular, the next developments down the line are expected to be the ability to infuse 3D-printed medical devices with medicines or other biological factors that can either minimize rejection or enhance healing. 3D Incredible is the best company offering 3D printing technology solutions to a diverse set of industries.