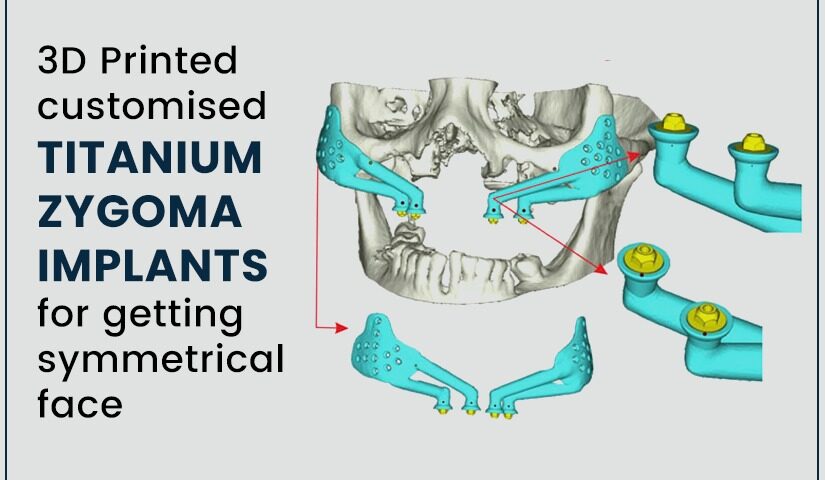

The zygoma defects that cause facial asymmetry can now be corrected with 3D-printed titanium implants specifically designed for the patient.

Zygoma reconstruction is different from the mandibular reconstruction. The primary distinction is that each patient will undergo the procedure with a unique outcome because the three-dimensional structure of the bone defect is significantly more complex than that of the mandible. Compared to the mandible, the zygoma shows more obvious external changes as a result of reconstructive surgery. In other words, the mandible has a more muted appearance after the implant than the zygoma.

The resulting exterior appearance is more complex and obviously indicative of zygoma changes. As a result, the implant for zygoma reconstruction should be made with more care and consideration. This suggests that there are more factors to consider both before and during the operation. The angle at which the implant is placed also limits its shape. The first 3d printing company in India, Incredible AM Pvt Ltd, provides zygoma implants that precisely conform to a patient’s contour and restore the aesthetics and functionality of the damaged part. This blog post will discuss where you can get a 3d-printed titanium zygomaimplant for a symmetrical face.

3D-printed zygoma implant created by Incredible?

The zygomatic defect patient undergoes clinical observation. Doctors now believe that patient-specific 3D-printed implants are the best option for reconstructing such facial deformities as a result of their observations. The 3D Incredible team consults with the concerned doctors about the design and entire manufacturing process before creating a zygomatic implant. The design is made with the assistance of medical professionals and the Incredible design team. Our designers produce exact designs for zygomatic implants using US FDA-approved software. Our group talks about the benefits of a personalized implant. The implant also aids the patient in regaining their confidence by maintaining their appearance and returning them to their pre-implant functioning. A distinctive aspect of the screw location is that it runs alongside the implant for better insertion.

The Incredible zygoma implants are manufactured in accordance with ISO 13485 requirements and tested for maximum safety and fit precision. When designing the implant, anatomical specifications, contours, and patient-specific bone thickness are taken into account. These implants have several advantages, including quick healing assistance, reduced invasiveness, and reduced risk. The implant’s precise placement and aesthetic perfection improve the recipient’s mental and physical health, allowing him to quickly get back to his usual routine. To ensure quality and safety, Incredible AM Pvt Ltd extensively tested its facility, equipment, and procedures.

A patient-specific titanium zygoma implant made by Incredible in Pune was used to treat the facial deformity of Mr Krishna Joggannavara, 17, by renowned Hubali, Karnataka, oral and maxillofacial surgeon DrManjunathVijapur. DrVijapur stated that the implant fits perfectly and the procedure to place it was easy.

Conclusion

For the best safety and fit accuracy, Incredible AM Pvt Ltd manufactures zygoma implants in accordance with ISO 13485 standards. Implants are made from the biocompatible material Ti6Al4V-ELI based on the patient’s anatomical requirements, forms, and bone thickness. The production unit maintains a class 10000 clean room, and the equipment, machinery, and procedures are meticulously verified and validated in order to ensure the quality and safety of implants.

In Pune, Incredible provides standard implants, bio models, and cutting guides in addition to patient-specific implants. For one, get in touch with us.