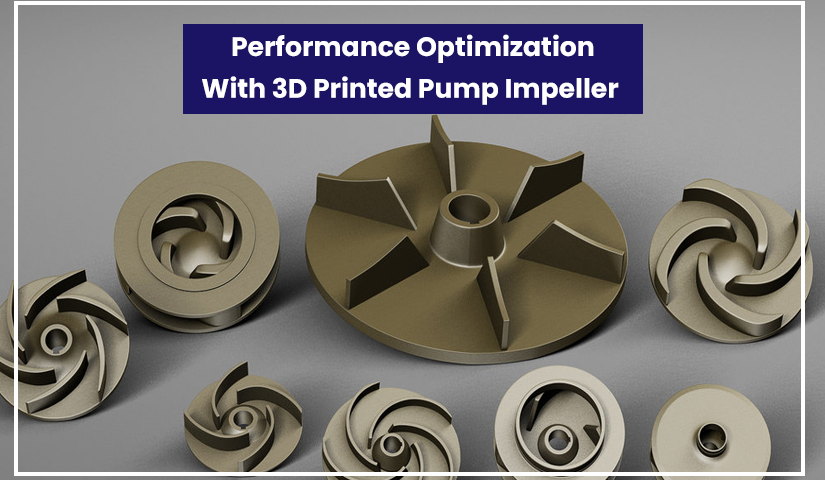

Designing a pump impeller is not an easy task. To get a pump with optimized performance is a step-by-step iterative process. It requires creating a design, building the impeller, testing its performance, tweaking the design, and repeating the process until an optimum design is obtained. To design and prototype complex shapes of impellers through conventional methods is an expensive and time-consuming job.

3D Incredible AM Pvt Ltd of Pune through the innovative 3d printing technology facilitates in optimizing the performance of the pump impeller and making the whole process fast and cost-effective. In this blog, let’s see how our technology is being helpful to the manufacturers who produce various kinds of impellers.

How does 3D Incredible facilitate the iteration of the pump impeller by 3d printing technique?

3D Incredible using 3d printing pattern eliminates the need for creating and modifying tools in each iteration.

We first create a computer-aided 3D (CAD) model of the impeller for casting. This quick process uses minimum human intervention and is able to deliver even a complex shape within a week. This CAD model is utilized in both conventional methods as well as 3D printing patterns.

The designing process of the impeller is crucial. It is done after careful calculation. The designer has to decide on the type and number of impeller blades and shape to make it efficient for converting the energy in the impeller.

After this, the model is sent for creating a 3d pattern. The time and cost of creating the pattern are lower than the conventional methods.

Once the pattern is created, it finally goes for the casting process. Here, in the casting process, the pattern is burnt out of the shell.

Now after the casting is created, it is tested to check its performance. In general, it may be possible that the performance is not up to the expectation. So, changes would be required in the impeller. In the conventional methods, tooling is modified to get a better result, for which extra cost and time are needed. But in 3d printing, the updated model is used to create a new 3d pattern that takes relatively little time and is sent for casting. Thus, the whole process saves time and money.

In addition, 3d printing also helps to evaluate several designs at one time. So, if a manufacturer decides to test several designs simultaneously and choose the best for production, 3d printing helps here. It drastically reduces the time taken for the whole process thus, making it a cost-effective deal. As a result, 3d printing helps in:

- Eliminating high tooling costs for conventional

- Reducing time

- Multiple designs can be evaluated at a time

- All this eventually helps the manufacturer to introduce the product in the market sooner.

To design the model of the pump impeller and its components and get their prototype, 3D Incredible make use of FDM, SLA, and other processes of 3d printing. The materials it utilizes for 3d printing of pump impeller are thermoplastics such as ABS or PVA, resins, etc.

Why should you prefer 3D Incredible for a 3d printed pump impeller?

Incredible AM Pvt Ltd of Pune has extensive experience of over 45 years in the field of manufacturing. We believe in making investments in state-of-the-art infrastructure, training our workforce, latest software, machines, resources, etc. With these, we cater to meet the demands of our clients who need improved and customized products.

We are ISO 9001, ISO 13485, and AS 9100 D certified for our quality services and products.

Conclusion

If you’re looking for getting a pump impeller of high-quality, Incredible AM Pvt Ltd offers you the best 3d printing solution. Our company offers competitive prices, excellent design, and software; quick and customized needs of our customers.