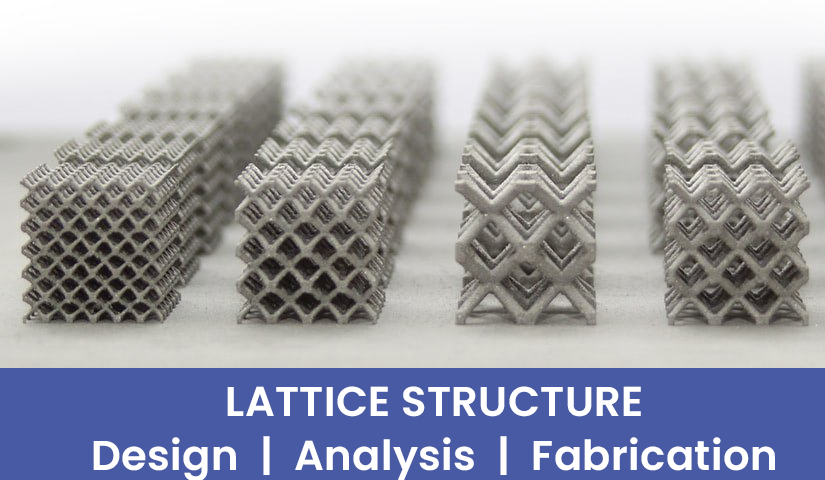

Additive manufacturing, the innovative technique allows time and cost savings in the product development process. It offers possibilities in creating free-form designs such as the creation of lattice structures. A lattice structure is a repetitive or non-repetitive 3-dimensional assemblage of connected nodes using beams. The collection of beams and nodes in the 3d structure gives regular and repeating 3d geometrical shapes, for instance, cubes, tetrahedrons, etc. Each unit of the lattice is called a cell. Lattice is regarded as uniform when it is formed from the repetition of the exact same cell in all directions or variable when it is formed of cells of different shapes and sizes.

3D Incredible AM Pvt Ltd of Pune is a one-stop-destination for 3d printing requirements. It manufactures lattice structures for different purposes since they offer multiple advantages such as the consumption of less material while distributing the required strength. To know about designing, analyzing, and fabricating lattice structures, read the whole blog.

How do we design and fabricate lattice structures?

Obtaining a 3d printed lattice structure is an intricate process. To obtain a 3d printed lattice structure, a generative design is used. Here, criteria such as a part’s connection points, mass limitations, and expected loads are defined. Further, an algorithm generates a number of solutions to meet the requirements. The most ideal of these solutions is selected through iteration. To create a lattice structure, several factors need to be considered. These are:

Cell structure: The cell structure that you can get through additive manufacturing is many and ever-growing. The common cell structure is cubic, star, hexagonal, diamond, octet, tetrahedron, etc. You can get uniform or mixed lattice structures for the desired application for your system. Different structures give different advantages such as some may be more efficient, some consume less energy while others may be aesthetically pleasing.

Cell size and density: The size and the density of cells depend upon the thickness and the length of an individual cell and the connecting nodes. Larger cells are easily printed but are stiffer, on the other hand, due to limited feature sizes, the printing of smaller cells is intricate but allows for homogenous system responses.

Material selection: The material used for 3d printing also impact the lattice properties. Smaller and denser cell goes well with elastomeric and soft materials in order to reduce sag during printing. While rigid materials allow a greater design range with a smaller number of cells with a large size.

Cell orientation: The angle at which a cell is printed has a great effect on the amount and placement of supports required, which in turn, affect the success of a print. A well-oriented lattice eliminates the need for separate supports as it is self-supporting.

How are lattice structures beneficial?

Though lattice structures are complex they have several benefits. Here, is the analysis of how a 3d printed lattice structure benefits?

- Increased strength to weight ratio: Latticing allows for the removal of the material in the non-critical and critical areas without compromising the functionality of the part. In decreasing the weight of the part, it helps to increase the strength to weight ratio.

- Increased surface area: Lattice structure provides increased surface area and makes the part suitable for applications such as heat transfer and chemical reactions.

- Act as a shock absorber: Lattice structure absorbs the energy and helps in protecting products from getting damaged due to collisions or drops. Thus, it is often used as a sacrificial component in a product.

- Cost-effective: Since 3d printed lattice structures can be made using less material without compromising the structural integrity of the component, the components or parts become cheaper.

Conclusion

Additive manufacturing of lattice structures has several benefits and is being used in manufacturing aeronautic components, automotive components, aerospace, etc. The state-of-the-art infrastructure of 3D Incredible plays a significant role in meeting the requirements of 3d printed designs and parts. We have an experienced workforce who are adept at creating intricate shapes and structures with the required strength and aesthetics. We design and fabricate lattice structures to suit your needs. If you require 3d printing products and services, we are there to help you. For your requirements, contact us.