STEREOLITHOGRAPHY (SLA)

This process offers quick prototyping capabilities with exceptional quality, good accuracy and nice surface finish, using UV laser as a source for curing liquid photopolymer. Widely used in jewelry, dentistry, casting and other applications.

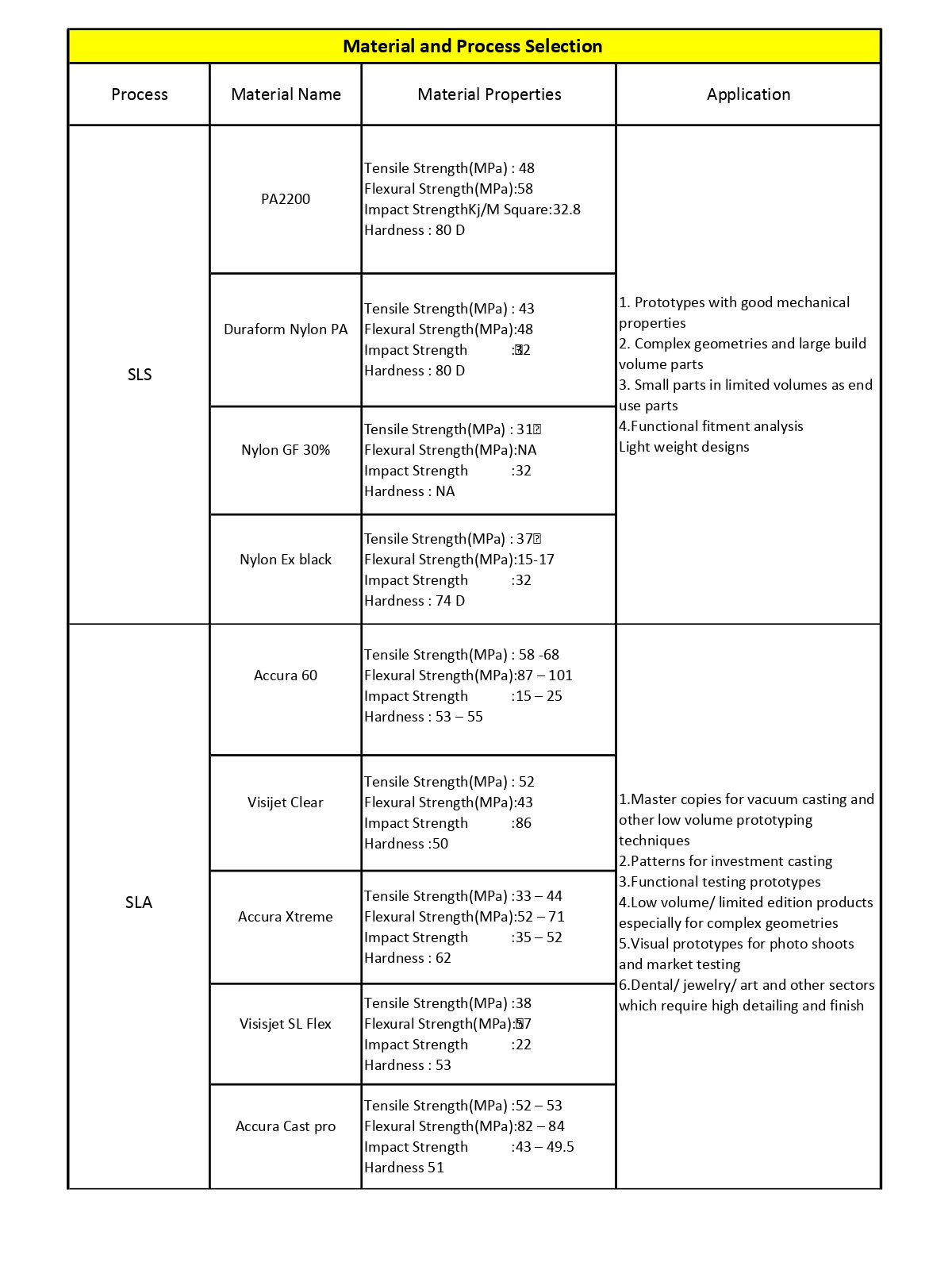

Application

- Master copies for vacuum casting and other low volume prototyping techniques

- Patterns for investment casting

- Functional testing prototypes

- Low volume/ limited edition products especially for complex geometries

- Dental/ jewelry/ art and other sectors which require high detailing and finish

Materials

- Acura 25

- Acura 60

- Visijet tough

- Visije clear

- Visijet white

Design Guidelines

- Min wall thickness: 0.8 mm

(<0.7mm thickness areas may have some issues) - Min clearance: 0.3 mm

(for Interlocking parts to aid fitment) - Min Details : 2.5 mm (text/ hole dia..)

- Max size: 650 x 650 x 450 mm (Larger parts done in parts and fitted/ glued)

Output Details

- Smooth, with tiny visible layers

- Accuracy: ± 0.2% (with lower limit on ± 0.2 mm)

- Layer thickness: 0.1mm

Post Processing

- Support Removal

- Curing

- Smoothing

- Primer

- Coating/ Painting

Other Details

- Lead Time: Depends on part (Min 2-4 days for dispatch. More for larger parts)

Achievable Feature Size:

| Feature | SLA | SLS |

| Build Volume | 145x145x175 mm | 340x340x600 mm |

| Thin walls | 0.6-0.8mm | 0.8mm |

| Holes | 0.8-1.0mm | 0.8-1.0mm |