In the past few decades, the ability to perform limb salvage surgery for primary bone sarcomas without compromising oncologic results is one of the most significant advances in orthopaedic oncology. The limitations in reconstruction techniques and endoprosthetic implant technology often translate into multiple revision surgeries in a patient’s lifetime for failures of the reconstruction.

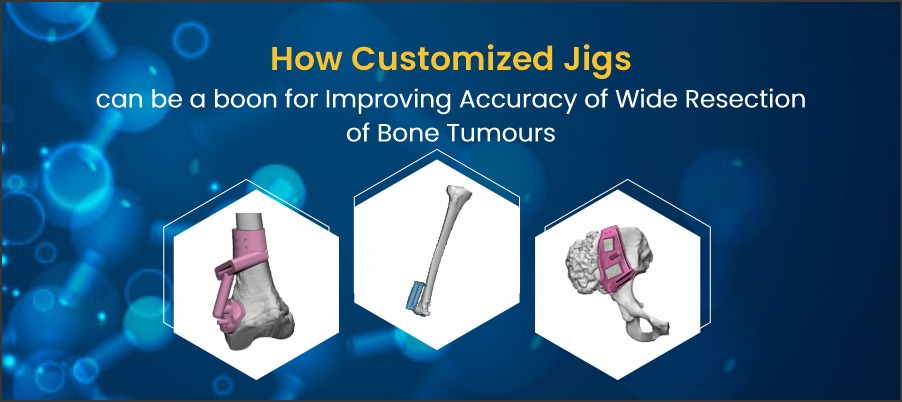

3D printing technology has proven to be a boon in these surgeries, providing support to the orthopaedic surgeons. Utilisation of customised 3D printed jigs greatly improves the accuracy of bone tumour resection.

About Customised 3D printed Jigs

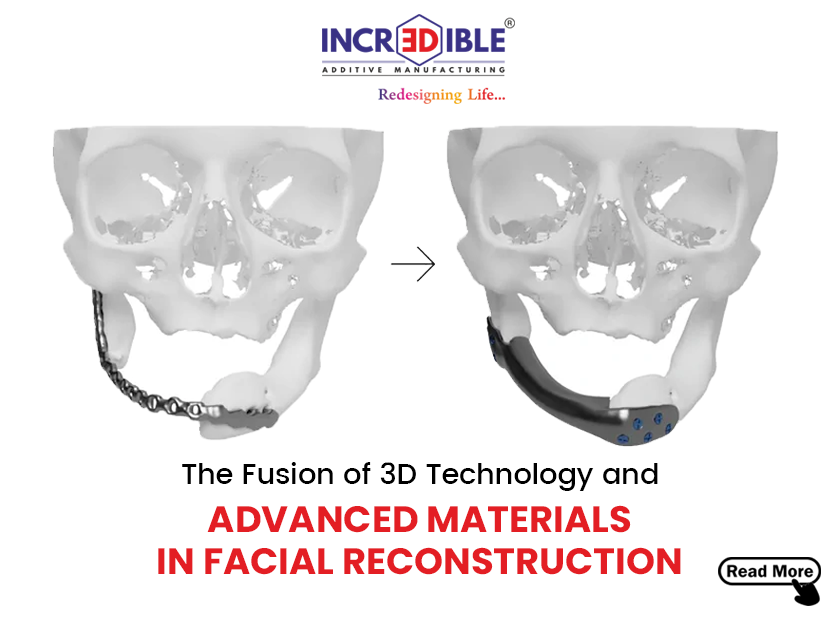

The design of a custom jig is typically based on either preoperative CT or MRI scans. The jigs are made of plastic and fit onto the bone surface in only one possible configuration, thereby orienting the surgeon to the proper bone location for correct jig placement. The jig can be designed to guide the path of surgical cutting tools, enabling the surgeon to exactly reproduce an ideal preoperative plan.

Improved accuracy with customised jigs

Custom jig-assisted technique for the joint-sparing resection of a bone tumour enables the surgeon to more accurately and reliably reproduce a given preoperative plan than a standard manual technique.

– Based on data collected, the surgeon aims to produce cuts that are at least 15 mm away from the ideal resection lines when using the manual resection technique. However, when using the custom jigs assisted resection technique, the surgeon can aim to produce cuts that are approximately only 4 mm away from the ideal resection lines.

– Extensive cartilage shaving is not a realistic option when attempting a joint-sparing resection. Digitally configured jigs would avoid contact with the cartilage in areas where there is a significant difference between the shape of the subchondral bone and the articular cartilage surface.

– The accuracy achieved with the custom jigs allows for new surgical advances in reconstructive orthopaedic surgery.

Conclusion

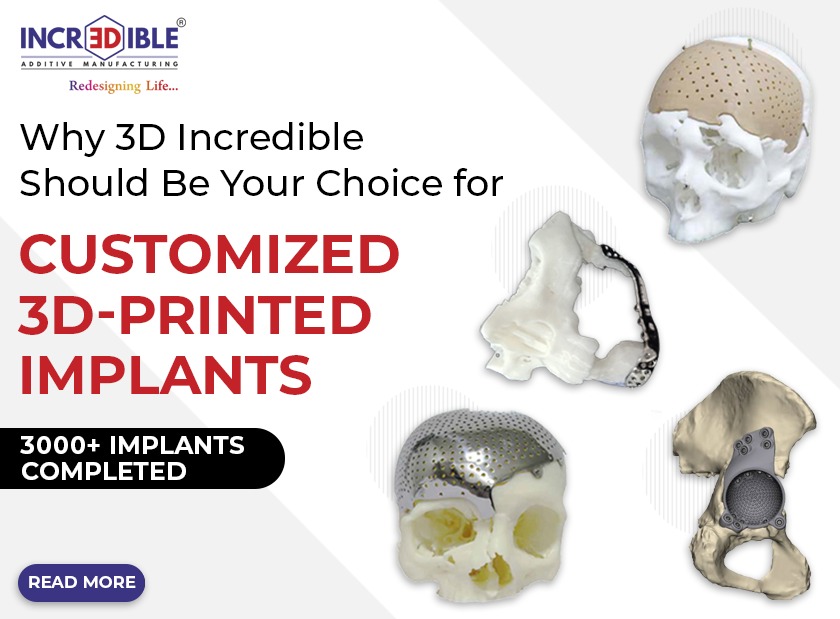

Customized three-dimensional (3-D) jigs have been shown to increase the accuracy of wide resection of bone tumour in comparison to freehand techniques. At the same time use of these jigs also lead to a better fit endoprosthetic implants because of accuracy of prepared site.3D incredible with its high-quality additive manufacturing has been able to produce customized implants for the patients under brand of LimbSal Ortho.3D printed jigs of customised material have proved to enhance the possibilities in these surgeries and improved its results in first attempt. Connect with us for these products for advanced surgical methods using additive manufacturing.