How 3D Printing Helps in the Evaluation of Ergonomics, Dimensions, and Accuracy of a Prototype

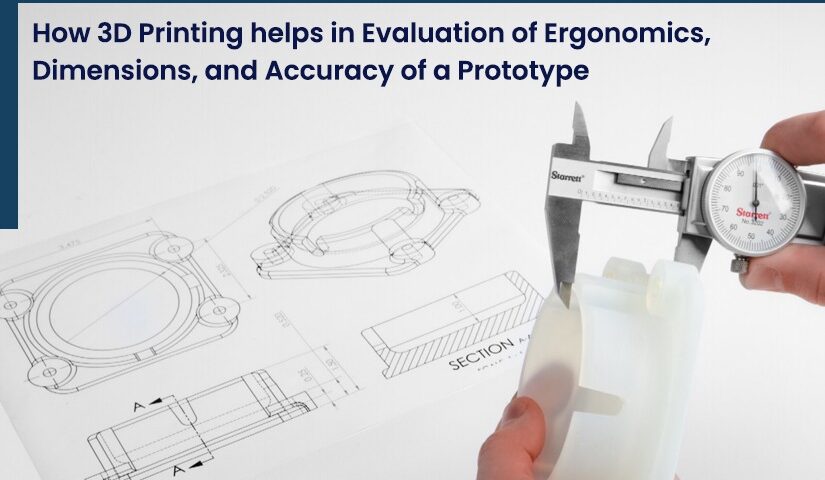

Prototyping is crucial for any development process. Machined prototypes have long been used for product development. However, with time, product development is becoming competitive every day, and companies are striving to launch their new products at the earliest. So, prototyping needs to be fast and precise. 3D printing, an innovative solution, provides a fast and precise prototype that helps omit the lengthy supply chain, design and procurement of tools and need for the costly setup that consequently saves time, cost, and effort of the product development process. 3D Incredible AM Pvt Ltd, based in Pune, is a pioneer in providing 3d printing solutions for all industries in product development using different 3d printing methods and materials. In this blog, let’s learn about how 3d printing helps in the evaluation of ergonomics, dimensions and accuracy of a prototype.

Benefits of 3d printing in developing prototypes

Evaluation of Ergonomics

3D printing has several advantages in product development, and one of its key features is that it helps in ergonomics evaluation.

In an ergonomic evaluation, 3d printing offers a quick and fairly cheap way to test multiple configurations and minor iterations of an idea until the correct feel is achieved. 3D printed prototypes enable you to for the accurate testing of ergonomic performance during the development phase. With such a procedure, you get customized ergonomics and tools that make working in manufacturing facilities much more comfortable and less risky. Moreover, for items like the contoured handles of a kitchen utensil, machined prototypes may be extensive and costly. This is because curved surfaces require a large number of finishing passes. On the other hand with 3d printing, producing a curved surface requires the same as is needed in a straight one.

Evaluation of Dimensional Accuracy

To obtain a dimensionally accurate final product, certain factors play a vital during the development of a prototype. These are precise designing, choosing the correct printing method, selecting the material from which the object will be made, and the size of the object. After finalizing the design, the right 3d printing processes are chosen to make the final product as accurate as possible. Here, let’s take up a few 3d printing methodologies and understand standard accuracy and also the drawback of these methodologies.

Fused Deposition Modeling (FDM)

This is one of the most common 3d printing processes that is used to produce quick prototypes. Industrial FDM printing encompasses a dimensional tolerance of ± 0.2% and a lower limit of ± 0.5mm. It creates objects by forcing out thermoplastics through a heated nozzle. Through this method, objects are printed one layer at a time and each layer cools at a different speed depending on its size and structure. This often causes warping and slight variations in the accuracy of the final object. Materials such as ABS, which require higher print temperatures, are at a greater risk of warping.

Stereolithography (SLA)

This 3d printing methodology produces smooth, visually accurate parts made from cured resin. Industrial SLA printing exhibits a dimensional tolerance of ± 0.1% and a lower limit of ± 0.3 mm. Since material such as resin takes time to harden completely, so when large, unsupported spans of material are printed, they might warp underneath their own weight or the weight of the surrounding layers. The material also shows warping when the object is peeled away from the printing bed during the final stage of the printing process.

Selective Laser Sintering (SLS)

This 3d printing process gives you fairly accurate dimensions when used to produce complex geometries. It exhibits a dimensional tolerance of ± 0.15% and a lower limit of ± 0.3 mm. The method uses lasers to sinter layers of powder together. Though it shows better accuracy than FDM, there is still a chance that the layers will not cool at the same rates. It often leads to warping, especially in larger SLS parts. The best way to get accurate dimensions is to leave the object in the powder bed until it is fully cooled.

Conclusion

3D Incredible AM Pvt Ltd, based in Pune, is a pioneer in 3d printing services in India. At our production unit, we give 3d printing solutions using 3d printing methodologies such as SLS, SLA, FDM, and MJF. We use the best materials to produce the most effective final products. To obtain dimensionally accurate and better ergonomics prototypes, 3D Incredible is the one-stop shop. For all your 3d printing requirements, connect with us.