Which Materials can be Printed at Incredible AM Pvt Ltd?

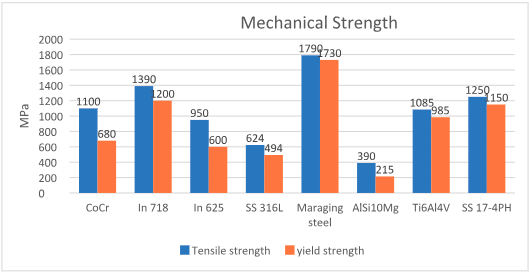

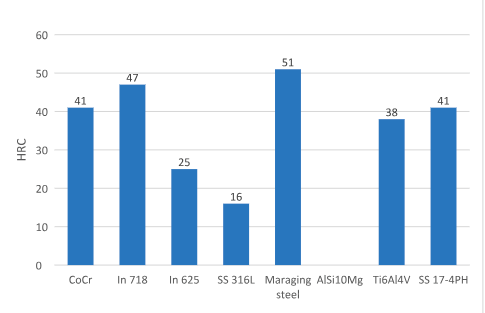

We can print 8 metal alloys specifically for Engineering and Medical industries. Cobalt chrome Titanium and SS 417-PH are primarily used in the medical field where as rest of the materials are applicable in Engineering field. The list of material is attached as below. For detailed information, please click the link given below.

Titanium (Ti6Al4V)

Stainless Steel (SS 316L)

Stainless Steel (174PH)

Cobalt-Chromium (CoCr)

Aluminium (AlSi10Mg)

Maraging steel

Inconel 728

Inconel 625

https://www.renishaw.com/en/data-sheets-additive-manufacturing--17862

Note:- New materials are constantly being added to the list, for more information, do contact us.

How to choose parts for metal 3D printing?

Metal 3D printing can produce intricate shapes which are not possible to produce otherwise. This capability has enabled designers to come up with innovative part designs which add value to either overall manufacturing process and/ product performance. Rapid prototyping, Hybrid Manufacturing, Reverse Engineering etc substantially optimise supply chain, where as topology optimisation, part consolidation, Lattice structure have significant impact on a product’s performance. Therefore, a part should be redesigned for better performance prior to printing. On the other hand, merely printing a conventional design which can be easily manufactured by CNC machining is not advisable.

What is the maximum size of a part which can be 3D printed?

Renishaw AM400 machine has build volume of 300X250X250 mm (H X W X B). If the part dimensions fit in to the build volume, the part can be 3D printed in the machine. In some cases, if a part is larger in size, the part can be sliced into two sections and printed separately followed by welding. In this case, welding line appears on the part, and also it affects overall quality, and therefore, if a part is functional, it is recommended to print the part as it is.

What is the delivery time?

Delivery time depends on various factors such as quality of data provided, material, quantity, design iterations, post processing activities required such as CNC machining or CMM inspection, need of fixture design and development for post processing etc. This process may take from 5 days to 15 days. On average, it takes about 8 days after payment has been received to dispatch a part.

How does costing work?

Costing is divided in 3 steps. Pre-processing, 3D printing and post processing. Pre-processing activity includes Designing, part feasibility, Reverse Engineering. Secondly, in the printing phase, the cost is dependent on number of factors such as build hours, support structure required, material, orientation of part etc. Finally, in the post processing phase, activities such as heat treatment, surface finish ,CNC machining, EDM etc activities do contribute. Every part doesn’t have to go through all above mentioned activities. Number of activities depend on case to case.

Is heat treatment mandatory?

In most of the cases, heat treatment is compulsory. During metal 3D printing process, residual stresses generated within the part geometry can lead to product failure while in application, and therefore, stress relieving heat treatment cycle is a must for functional parts. On the other hand, parts which are merely showpieces/non-functional can be delivered without being heat treated.

What data you need to provide to get 3D printed parts?

We need high resolution .stl CAD file of the part along with casting and machining drawing if applicable. We also need filled ‘Product Request Form’ which is available online on our website or you can get it from one of our representatives. The CAD file can be directly uploaded to our website.

How much density is achievable?

Most of the parts have density above 99.5% Up to certain extent we can control internal porosity as well. Casted parts have density around 95-97% so 3D printed parts can certainly be adopted in most of the applications.

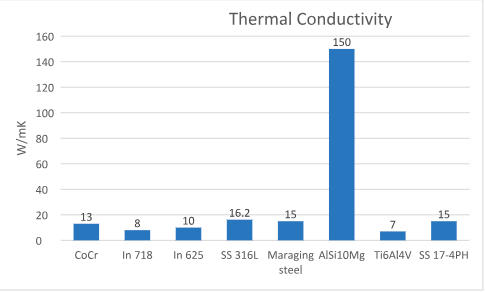

Which Material is best suitable for heat transfer applications?

Aluminium has very high thermal conductivity, and therefore can be used in the heat transfer applications.

How much accuracy is possible?

3D printed parts produced with SLM process are quite accurate. This process can achieve near net shape of a part with 0.2 mm (200µm) accuracy. Additionally, CNC machining can be done for further improvement up to 5-10 µm. We can print minimum wall thickness of around 0.5 mm depending on the height of the part. Circle of 1 mm diameter can be printed with high accuracy depending on the height.

How do we ensure product quality?

Process parameters have been established & validated by experimental testing. We import high purity metal powder which goes through extensive testing at ‘Incredible AM powder lab’ prior to printing. We follow ISO 9001& ISO 13485 quality control and assurance norms to deliver the best possible quality. Periodically, 3D printed parts go through comprehensive NABL accredited lab testing for quality assurance. Additionally, a sample part is printed and stored at Incredible AM part library along with every Medical Implant order in case our customer would like to re-assess the part which has been fitted into human body.

What surface finish is achievable?

3D printed parts have Ra values ranging from 7-12 µm depending on the material, but we can alter the value by post processing activities. These activities are capable of producing ‘Matt Finish’ and ‘Mirror surface finish’ where matt finish hardly removes any material from the surface, around 200-300 mg. However, mirror surface finish needs 0.5-1 mm additional stock for achieving 1-2 Ra value. Matt finish can achieve up to 3-5 Ra.

Is hybrid manufacturing possible with metal 3D printing? If yes, which material can be Hybrid manufactured?

Printing one material over other is a challenge, however it is possible. The difficulty arises at the interface where one material is forced to fuse metallurgically with another. Material properties such as thermal conductivity and coefficient of thermal expansion are key factors in the success. As a rule of thumb, closer the properties, chances of success are higher. For example, H13 and Maraging steel can be printed over each other because their thermal and mechanical properties are similar, and both are tool steels. Additionally, there are many more factors to it, but material property is a key.

Which parts are difficult to 3D print?

Spring, Threading, Seal, Gasket etc parts shouldn’t be metal 3D printed

What Services Incredible AM do provide?

Designing (Topology Optimisation, Conformal Cooling), Reverse Engineering, Metal 3D printing, Heat treatment, Bead Blasting, Ultrasonic Cleaning, CNC Machining, CMM inspection, Surface Coating/Plating

Does Incredible AM design Conformal Cooling Channels for customers?

Incredible AM has identified a designing vendor who has extensive experience in Mold and conformal cooling channel design. If customer is willing to design the channels at their end and provide .stl file, it is also acceptable.