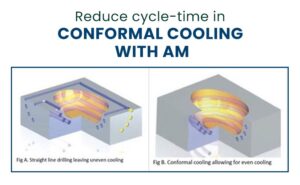

What is Conformal Cooling?

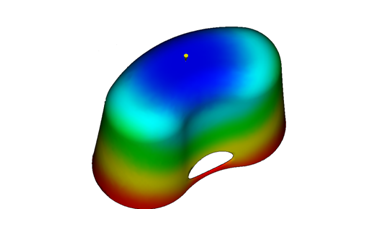

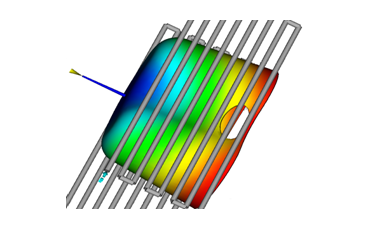

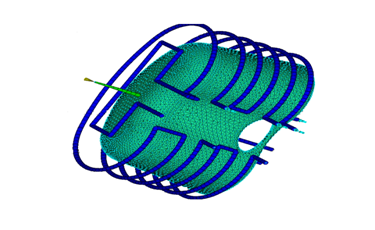

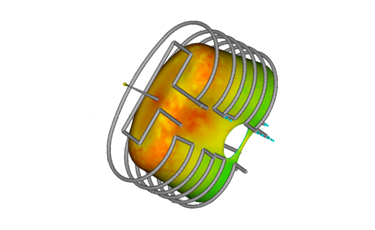

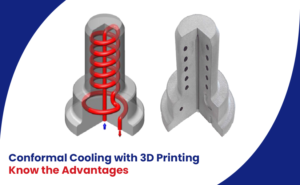

Complex plastic parts take longer to cool in Injection moulding process. Curved surface and varying wall cross section of a plastic part hinders uniform cooling which results in residual stress built-up, introducing warpage. In such geometries, achieving uniform cooling is challenging with conventionally straight drilled channels. Conformal cooling channels can be 3D printed in a variety of cross sections such as rectangular, circular, elliptical, half-circular etc. These channels need not to be straight and they follow part’s cross section. Cooling channels can be circular, elliptical, spiral etc. These complex cooling channels improve the overall efficiency of the plastic part process resulting in reduction of cooling cycle time by up to 40% along with improvement in surface finish. Increase in production may obsolete a machine or two in a manufacturing plant, consequently reducing labour, space and power requirements.

Benefits

- Increase in Injection moulding productivity by up to 40%

- Optimise inhouse resources such as machines and allied facilities

- Minimum warpage and shrinkage of plastic parts

- Improved surface finish quality of plastic parts

- Increased tool life

- Faster delivery time

Application Industries

Process