Since its inception in the 1980s, metal 3D printing, also known as additive manufacturing, has come a long way. metal 3d printing services began as a tool for rapid prototyping and has now expanded to include a variety of technologies. 3D Incredible has experienced a tremendous increase in the number of costumers that are aware of the benefits of the technology. Tooling aids, visual and functional prototypes, and even end-use parts are among the applications and use cases that differ by industry.

In industries such as aerospace, tooling, oil and gas, numerous tools are used which wear out and significant cost is involved in replacing the wear out spare by whole new spare or tool. Metal 3d printing with a hybrid building technique gives the liberty to save lot of time and cost involved in new tooling development for maintenance work.

Benefits of Hybrid Building of Functionally Graded Materials with Metal 3D printing in different fields are as given below.

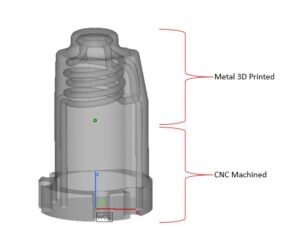

Concept of Hybrid Building with Metal AM technology

Aerospace:

Hybrid Building enables repairing of damaged and wore out aerospace components like turbine blades, aircraft spares parts by reprinting the damaged region on existing part. This prevents from replacing whole part and also the cost.

Tooling:

Injection molding and other forming tools gets wear out after certain number of cycles which requires large cost and time in making of new tool. The additive manufacturing with hybrid building technique saves this loss by enabling reprinting of tool on existing base insert and save large tooling cost and time.

Oil and gas:

The continuous operation industry where a stoping of opearation for just an hour results in large economic loss requires quick availability of spares and repairing of the part. Here the hybrid additive manufacturing plays a vital role in quick repairing of parts with best same functionality and least time.

Quality and performance of hybrid built part:

The hybrid manufacturing is the printing of new part on existing block with high power laser which ensures proper welding of two components. The proper heat treatment gives the homogeneous mechanical properties with desired quality and performance. The properties of the hybrid building is regularly validated at 3D Incredible by doing testing of tensile, hardness, welding strength etc.

The dimensional tolerance equivalent to machining accuracy is achieved by doing post printing finishing operations.

Other benefits of hybrid building with metal AM:

Metal AM is more economical for complex topology parts. The component which has simple topology or profile at one end and can be manufactured easily by conventional machining and has the complex topology at other end which cannot be easily machined and needs 3d printing, such components can be made by hybrid manufacturing by first machining the simple profile part first and building remaining part on it. This saves the 3d printing cost of simple profile part.

Conclusion

Hybrid building is beneficial in following ways:

Avoid replacement of whole part in wear out condition, by building the wore out region

Saves lead time involved in developing of full part again.

Saves cost of 3d printing by doing simple region by machining and printing complex region the machined block

Incredible AM Pvt Ltd situated in Pune India is a 3D Printing service bureau providing all solutions of 3D Printing in metal and plastic in all sectors of engineering and medical. With AS9100D, ISO13485 and ISO9001, the company has world-class infrastructure run by AM experts.