limb salvage surgery for treatment of Chondrosarcoma of Pelvic

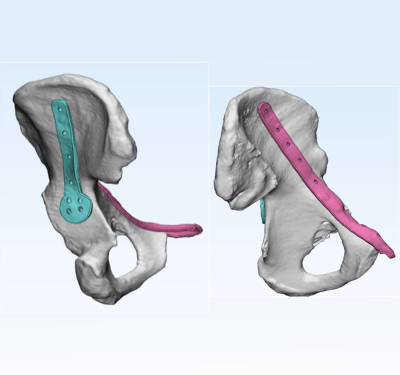

Implant Specifications:

- Name of the surgeon : Dr. Manish Agarwal

- Place : P. D. Hinduja Hospital, Mahim, Mumbai

- Implant size : Anterior plate: 136*60*116, Posterior plate: 42*23*107

- Surface finish : Matt finished both side

- Material : Patient specific anatomy model, customized bone resection jig

Introduction:

Incredible AM Pvt. Ltd. is the first company in India working exclusively with Medical 3D printing in a certified world class facility. The company has built the facility as per FDA norms. It is certified with ISO 13485 and ISO 9001. Key features includes Class 10000 clean room, US-FDA approved software, state of the art equipment and also an excellent team of doctors, engineers, biomedical engineers, CAD designers and medical consultants who are there to deliver outstanding services to doctors, hospitals & patients with complete validation & tests conducted to certify the process & product. Incredible deals with Customized Implants, Standard Implants, Bio models as well as Cutting Guides

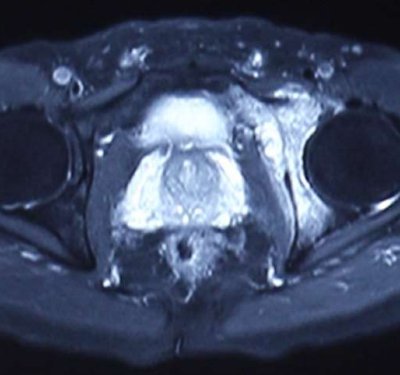

Tumor in left groin region

Background :

A male patient of 50 years old hailing from Mumbai, Maharashtra, presenting with complaints of pain in left groin. Imaging followed by Biopsy concluded Grade II Chondrosarcoma. Dr. Manish Agarwal, India’s Leading Onco Orthopedic Surgeon in P. D. Hinduja Hospital, Mumbai, Maharashtra decided to go for extracorporeal resection & reimplantation (ECRT) as local line of treatment. For this, customized cutting jigs & customized implant were planned and ordered.Solution:

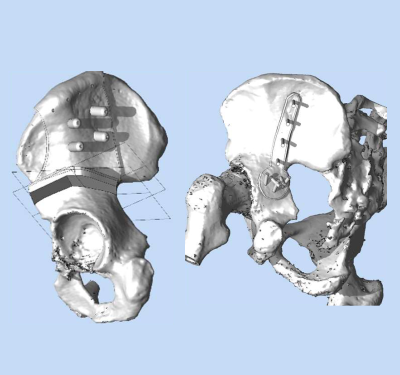

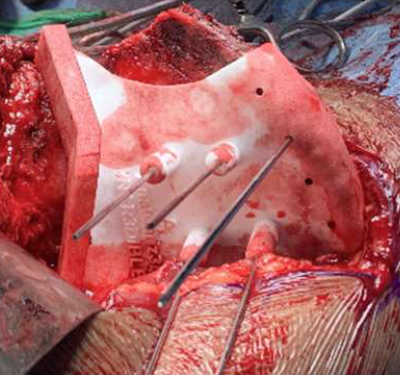

Dr. Manish Agarwal, India’s leading Onco Orthopedic surgeon in Mumbai, Maharashtra being a pioneer in using treated tumor bone/ECRT as a method of reconstruction aided surgeries studied medical history, imaging and histopathology reports. It was decided to proceed with ECRT line of treatment. Salvage of acetabulum with ECRT is more of challenging procedure due to complex anatomy of hip, limitation on access due to vital organs in pelvis and particularly due to functionality of load bearing joint. Hence Dr. Manish Agarwal decided to use patient specific cutting guide and patient specific anterior and posterior plate to fix radiated bone fragment back to the position to give maximum functional benefit to the patient. 3D Incredible team discussed with Dr. Agarwal, the designing and entire manufacturing process. The case was initially started with surgical planning and case stimulation with the help of US FDA & CE approved Materialise Mimics software by superimposing CT & MRI DICOM data & anatomical model. As anatomical model maintained 1:1 ratio with the anatomy, hence showed excellent detailing of the tumor, the model was also used to design jig & implant on actual bone, which helped the presurgical planning to be more accurate. Once the planning was finalized, the surgery was to be accompanied with not only customized plates but also cutting guides & jigs. Customized jig helped in precise cutting of hip bone tissue particularly useful with the narrow margins. Jigs are manufactured using biocompatible Nylon material which is autoclavable. The design was completed with valuable inputs between the doctor and the 3D Incredible design team together. The benefits of a 3D printed implant was it`s customization which resulted in an anatomically perfect fitted implant. The variable sizes help in strengthen the particular area required. Finite Element Analysis was carried out at the design which to determine the strength, stability and functionality of the plates. The specialty of the design was the screw location and direction were defined as per surgeon’s requirement to get maximum bone purchase and to achieve the same pre-defined trajectory of screws provided. Excellent combination of combi and locking holes provided to ensure strong and stable hold of bone fragment.

Cutting guide jigs & implant design

Cutting guide jigs

Intra-Op resected

Radiated bone tumor fragment

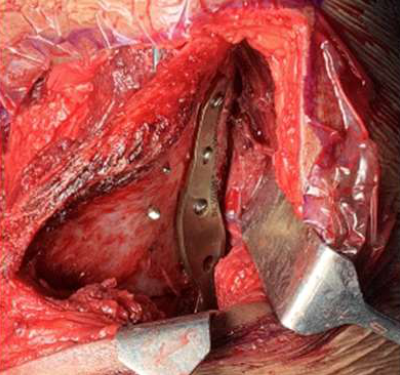

Implantation of Anterior

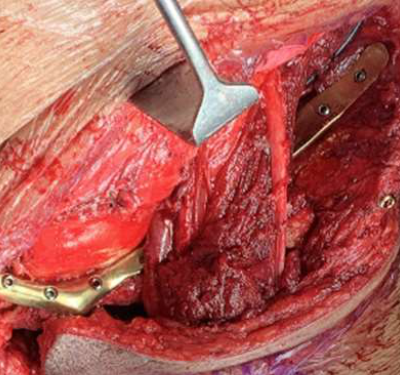

Implantation of Posterior plates

Quote from Doctor :

“Custom made cutting jigs allowed us to make precise bone-cuts as planned. Custom made plates further made reconstruction of the bone with anatomically contoured plates with desired screw trajectory for maximum hold, Custom plate allowed us to preserve the growth plate. We could customize the locking by predeciding the screw direction and position within bone. The custom plate fits the deformed bony contours and aids reduction.”

Post- OP radiographic images

Conclusion:

Implant was manufactured under ISO 13485 guidelines & tested to give an accurate fit & utmost safety. Cutting guides and jig from 3D Incredible helped the surgeon to give an accurate cut and complete the surgery in one go. Once the resection was done, customized plates from 3D Incredible was implanted. Plates were manufactured using Ti6Al4VELI, a biocompatible material; as per anatomical requirement, contour and bone thickness which are patient specific. 3D Incredible customized cutting jig and customized plates helped to reduce OT as there was no further adaption of standard implant required on OT table. Anterior and Posterior plates have been designed in such a way that ensure proper holding of acetabulum to enhance faster recovery and excellent functional results post ECRT surgery. Incredible AM Pvt Ltd has undergone rigorous testing & validation of its plant, equipment and process to ensure safety and quality.Contact Us

Plant Address

Gat No. 699/1, Koregaon Bhima,

Behind Kalyani Forge, Tal- Shirur,

Dist- Pune 412 216,

Maharashtra, India.

Landline: +912137667900

Landline: +912137667934

Pune Office Address

G-11/S11, Paresh Industrial Complex, Shankar sheth Road, Pune 411037, Maharashtra, India.

+91 7030940790 (Engineering)+91 7030952720 (Medical)

info@3dincredible.com